What is a Belleville Spring Washer

In many

practical situations, you may have come across washers that were not totally

flat, but curved in nature. These curved washers are called Belleville spring

washers.

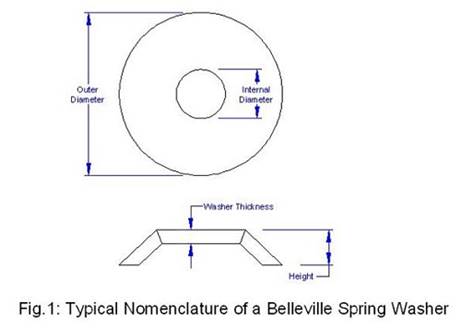

How They Look

As you

can see from the picture above, a Belleville spring washer is curved in cross

section. Apart from that' everything is similar to an ordinary washer. It has a

centre hole, through which bolt is inserted for assembling it.

How a Belleville Spring Washer Works

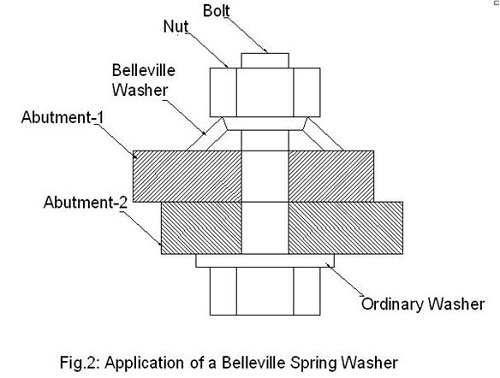

A

Belleville spring washer is placed at one end of a bolted joint in place of

ordinary washer. Specific torque (depends upon the Belleville spring washer

design) should be applied for tightening the nut. After the tightening is done,

the spring action of the Belleville spring washer protects the joint from

loosening even in a rough environment.

Parallel and Series stacking of Belleville spring washer

If a

bolted joint requires multiple Belleville spring washers to be used at a place

then the washers can be assembled in two possible ways:

1.

Butting the concave surface of the top washer to the convex surface of the

bottom washer.

2.

Butting the convex surface of the top washer to the convex surface of the

bottom washer or vice versa.

The first

case is called “Parallel" stacking and the second case is

called “Series" stacking.

What Are the Advantages of a Belleville Spring Washer over

Ordinary Washers

○ Belleville spring

washer offers continuous clamping pressure to the bolted joint, as a result the

bolted joint does not become loose while operating in

a vibration prone environment.

○ As compared to a

helical spring washer, it takes less space for installation.

○ Belleville spring

washers can be assembled in parallel to increase the load-withstanding capacity

of the joint.

○ Similarly,

deflection of the joint can be increased by assembling multiple washer in

series.

Conclusion

Curved

cross section of Belleville spring washer produce spring action in

the bolted joint. To get the full benefit of a Belleville spring washer,

check out the Belleville spring washer design load and apply tightening torque

accordingly.