Design an Idler for a Conveyor Belt System

The

idlers are an important part of a belt conveyor system; they provide stability

to the conveyed materials. There are mainly three types of idles used in the

industry namely, flat idlers, trough idlers, and garland idlers. In this

article we will discuss only the flat type belt conveyor idler design.

The Basics of Flat Idler Design

Typically,

the following inputs are used for starting up the design process of the flat

idler:

○ Capacity of the

conveyor generally expressed in tons per hour.

○ Bulk density of the

conveyed materials generally expressed in tons per cubic meter.

○ Conveyor belt width

generally expressed in meters.

○ Belt speed generally

expressed in meters.

The

output aims from the design process are:

○ The spacing of the

idlers generally expressed in meters.

○ The idler speed

generally expressed in meters per second.

○ Load on each idlers.

○ Idler diameter

generally expressed in meters.

The

following design equations are used across the industry for calculating the

different design parameters of the flat idlers:

○ Spacing of the idlers

S =

(8*T1*H)/ (mb+ml)*g

..1.1

Where,

S is in

meters

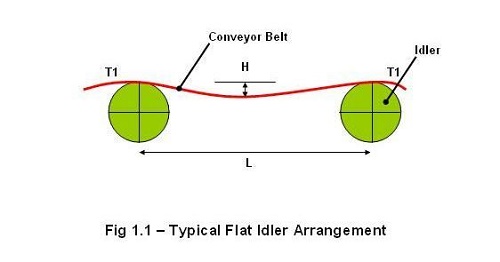

T1= Belt

tension near the idlers as shown in the picture (N)

H=Belt

sag (m)

mb = weight of the belt (kg/m)

ml =Weight of the conveyed material (kg/m)

g

=Acceleration due to gravity

○ The weight of the

conveyed material can be further calculated as

ml= (10*W)/ (36*V)

1.2

Where,

mb is in kg/m.

W =

Capacity of the conveyor (tons per hour)

V = Belt

speed (m/sec)

○ Idler speed

N =

(60*V)/ (Π*D)

1.3

Where,

N is in

RPM.

V = Belt

speed (m/sec)

D =

Diameter of the idlers

Loads on

each idlers

○ F= (10*W*S*g)/

(36*V)

1.4

Where,

F is

in Newtons

g =

Acceleration due to gravity

W =

Capacity of the conveyor (tones per hour)

S =

Spacing between the two idlers.

V = Belt

speed (m/sec)

○ Maximum bending

stress on the idlers

b=

(8*F*L)/ (3*Π*D3)

..1.5

Where,

b is in Newtons per

square meter

F = loads

on each idlers (Newton)

L =

length of the idlers (Meter)

D =

diameter of the idlers (meter)

One Practical Belt Conveyor Idler Design Example

Now,

lets see how to use the basic design equations for actual design purpose. We

will take the following data as input:

Capacity

of the conveyor W = 1000 t/h

Belt

speed V =1.68 m/sec

Belt

tension near idler T1=50000 N

Idler

length L =1.2 m

Belt sag

= 0.015 m

Weight of

the belt mb=15

kg/m

Idler

speed N= 50 rpm

Design

procedure:

○ First, we will

calculate the weight of the conveyed material using the eqn.1.2 as:

ml = (10*1000)/(36*1.68) = 165.34 kg/m

○ Now, to calculate

the spacing between the two idlers we will use the eqn.1.1

S=(8*50000*0.015)/(15+165.34)*9.81

= 3.391 m

○ The diameter of the

idler can be calculated from the eqn.1.3 as below:

D=

(60*1.68)/ (3.14*50) = 0.64 m

○ Total load acted on

each idler can be obtained from the eqn.1.4 :

F=(10*1000*3.391*9.81)/(36*1.68)=5500

N

○ Maximum bending

stress applied on each idlers can be obtained from the eqn.1.5 as below:

b=

(8*5500*1.2)/ (3*3.14*0.643) = 21385.176 N/m2

If the

maximum bending stress calculated from the above equations is higher than the

accepted limit of the bending stress then, you have to reconsider the input

assumed parameters, for example you may have to set the lower idler speed or

you have to think of the lower belt sag value, so that idler spacing got

reduced and so the load per idler.

Conclusion

There are

three types of idlers used in the conveyor industry, out of which only the flat

belt conveyor idler design calculations are discussed here theoretically. We

have not used the factor of safety in the design calculations here, or in other

words the factor of safety is considered as one throughout the calculations.

The theoretical calculations are ideal for the preliminary design. FEA

tools like Ansys or Pro Mechanica should

be used for the final virtual validation of the design.