Shaft Design for Combined Bending and Torsion Load By

Equivalent Bending Moment and Torque Method

This

article will discuss drive shaft design concepts and shaft design formulas for

shafts subjected to combined bending and torsion loading.

In a

previous article we have seen how to design a drive shaft only for

bending. But, for many practical shaft design problems you have to

consider bending as well as torsional load when designing the shaft. Such drive

shaft design problem can be solved in two ways:

○ By calculating the

equivalent bending moment and toque of bending and torsion.

○ By using the

principle stress concept.

In this

article we will limit our discussion to the equivalent bending moment and

torque method.

Equations to Be Used

○ Equivalent bending

moment equation:

Meqv. = 0.5 [M + SQRT (M^2 + T^2)]

..eqn.1.1

○ Equivalent torque

equation:

Teqv.

= SQRT (M^2 + T^2)

..eqn.1.2

○ Equation of bending

stress:

Tb =

(32*M/(pi*d^3)

eqn.1.3

○ Equation for

torsional shear stress:

St =

(16*T)/(pi*d^3)

.eqn.1.4

Where,

Meqv. Equivalent bending moment

M

Bending moment

T Torque

Tb

Bending stress

St

Shear stress

d

Diameter of the circular shaft

Shaft Design Problem for Combined Bending and Torsion

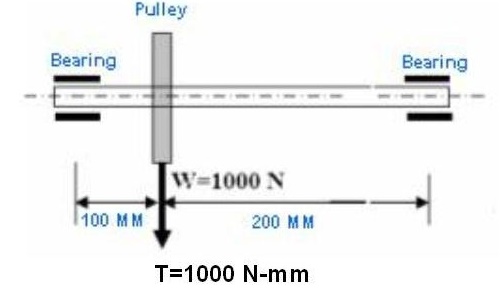

Refer the

picture above, apart from the self weight (1000N) of the pulley a torque (1000

N-mm) due to belt tension is also applied on the shaft. Assuming the maximum

allowable stress in tension for the shaft material as 40 MPa, The following

steps need to be performed for obtaining the minimum diameter of the shaft as

per maximum principle stress theory:

○ Maximum bending

moment applied on the shaft = 1000 * 100 = 100000 N-mm

○ Applied torque is

given as 1000 N-mm.

○ Equivalent bending

moment (from eqn.1.1):

Meqv.= 1207 Mpa

○ Equivalent torque (

from eqn1.2):

Teqv.= 1414 N-mm

○ Maximum principle

stress (from eqn 1.3):

Sigma1

= Tb= (12301/d^3)

○ Now for getting

minimum shaft diameter as per maximum principle stress theory, we have to

equate Sigma1 with allowable stress, hence:

40 =

(12301/d^3)

Or, d

= 6.7 mm

Conclusion

Most of

the time you will come across a shaft design problem with the combination of

bending and torsional loading. Accurate use of the four shaft design formulae

will lead to the solution for most cases. You can get help from the FEA

tools as well.