Five Useful Tips for Plastic Part Design

Plastic

part design is a specialized job and a little different than product design

using metals. Five important tips for plastic part product design and

engineering will be discussed in this article.

From your

car to your computer, you will find the use of plastic parts in almost

everything everywhere around you. Most of the plastic parts are manufactured by

some type of molding process. As a design

engineer, the following five tips will be handy for designing plastic parts:

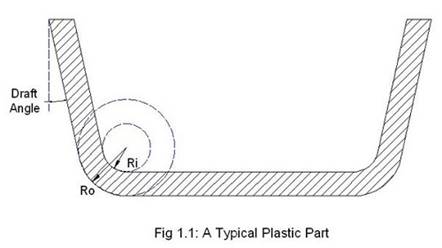

1. Draft Angle: Draft angle is the

slant angle of a plastic part (as shown in the picture above). Providing a

proper draft angle is important for the (easy) removal of the plastic part from

a mold.

Draft angle should be as much as possible.

Standard

practice is having a draft angle of 1 to 2 degrees if there are no textures or

lettering in the surface. In case of lettering and textures, an additional

draft angle of 1.5 degrees per 0.025 mm depth of the texture is recommended.

2. Wall thickness: While

designing the plastic parts, design it for the wall as thin as possible. The

thicker the wall, the slower the cooling rate and the greater the chance of

getting defective plastic parts. If you need a thicker wall, go for it but make

sure the wall thickness is uniform throughout the part. In case you cannot

avoid uneven wall thickness, then assure gradual changes in the thickness.

3. Radius: Avoid sharp corners

in order to minimize stress concentrations and molding defects in the

designed plastic part.

The

recommended value of radius is at least equal the thickness of the plastic

part. And the centre point for the internal and the external radius should

coincide. In other words, external radius = internal radius + thickness.

4. Rib: One method of

avoiding warpage in plastic part is providing one or more ribs in the design.

At the same time, the thickness of ribs should be kept to minimum or it will be

subjected to molding defects

like shrinkage.

The

thickness of the rib should be in between ½ to 1½ times the wall thickness of

the plastic part. The height of the rib should be less than three times the

thickness of the plastic part. A one degree taper angle is recommended for rib

design.

5. Boss: Sometimes you may

have to design plastic parts with bosses. Standard practices for designing

bosses in your plastic part are:

6. The ratio of the

outer diameter to the inner diameter of the boss should be between 2 to 3.

7. The boss wall

thickness should be around ½ to 1½ the wall thickness of the plastic part.

8. The height of the

supporting gussets for the boss should be around 2/3 the height of the boss

itself.

9. The taper angle for

the boss should be around 1 degree.

Conclusion

The

plastic part design procedure has some similarities with casting design.

However, the thickness of casting components is normally higher than that of

plastic parts. CAD modeling of

the plastic part can be done using ProE or Unigraphics. However

specialized CAD packages are also available.