The 3-2-1 Principle of Jig Fixture Design

Jigs and

fixtures are used extensively for mass production. This article will explain

what the 3-2-1 principle is and how it is important for jig and fixture design.

One

method of reducing manufacturing cost per component is to reduce

machining cycle time. The manufacturing cycle time can be reduced by

reducing nonproductive time

like loading, unloading, and the placing of work piece onto the machine. Here

jig and fixture design has important role to play. Productive time for a

machine is the time required for metal cutting operation by the

machine.

In short,

the fixture is a tool that ensures correct and quick clamping (or loading) of

the workpiece with respect to the machine tool.

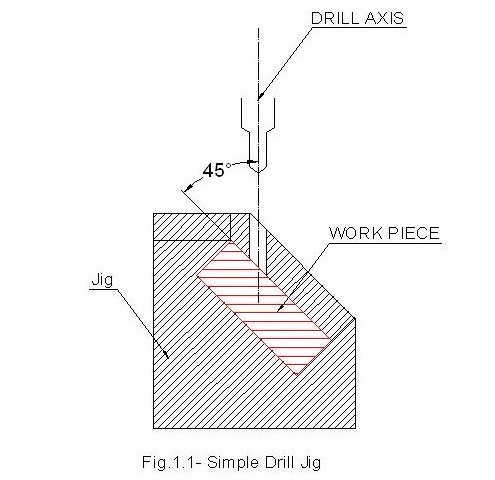

For

example, you have a drill machine and want to make a 10mm diameter hole at the

point of intersection of the two diagonals of a square plate. The hole should

be inclined at 45 degree angle with the surface. Now you have two choices,

either you clamp the workpiece with the vice or use arrangement like below:

3-2-1 Principle of Fixture Design

For a

fixture designer, the major portion of design time is spent deciding how to

locate the workpiece in the fixture.

You know

that any free body has a total of twelve degrees of freedom as below:

6

translational degrees of freedom: +X, -X, +Y, -Y, +Z, -Z

And 6

rotational degrees of freedom:

-

Clockwise around X axis (CROT-X)

-

Anticlockwise around X axis (ACROT-X)

-

Clockwise around Y axis (CROT-Y)

-

Anticlockwise around Y axis (ACROT-Y)

-

Clockwise around Z axis (CROT-Z)

-

Anticlockwise around Z axis (ACROT-Z)

You must

fix all the 12 degrees of freedom except the three transitional degrees of

freedom (-X, -Y and -Z) in order to locate the workpiece in the fixture. So, 9

degrees of freedom of the workpiece need to be fixed.

But, how?

By using the 3-2-1 method as shown below:

Rest the

work piece on three non-collinear points of the bottom surface

(XY), and you will be able to fix the +Z, CROT-X, ACROT-X, CROT-Y and ACROT-Y degrees

of freedom.

Now, rest

the workpiece at two points of side surface (XZ), and you will

be able to fix the +Y and ACROT-Z degrees of

freedom.

Now, rest

the workpiece at one point of the adjacent surface (YZ), and

you will be able to fix the +X and CROT-Zdegrees of

freedom.

So, you

can successfully fixate 9 required degrees of freedom by using

the 3-2-1 principle of fixture design.

Conclusion

The jig

and fixture are tools used for holding the workpiece in a correct location for

mass production. Various types of fixtures (like drilling

fixtures, milling fixtures, and welding fixtures) are used in

industry. The 3-2-1 method is the fundamental principle for all types of

fixture design.