Jigs vs Fixtures

The terms

“jig" and “fixture" are many times referred as the synonyms of each

other, sometimes both the terms are used together as “jig fixture."

Although, both jig and fixture are used in mass production process,

functionally the two are different tools.

What is a Jig?

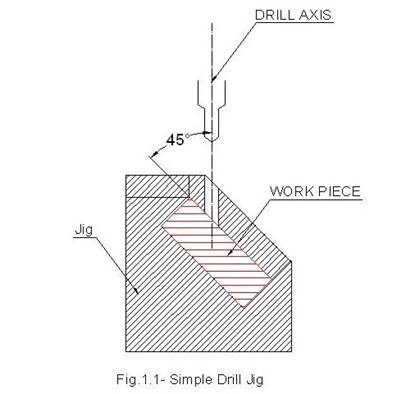

In simple

terms, the jig is a tool that guides the cutting (or machining) tool. The most

common type of jig is the drill jig, which guides the drill bit for creating

holes at desired locations. Using drill jigs increases production rate

drastically by eliminating the time spent using a square scriber, height gauge,

centre punch, etc. The picture below shows the functionality of a simple drill

jig:

Like

drill jigs, welding jigs and woodworking jigs are also used in industry quite

extensively. Woodworking jigs are useful for creating intricate wooden profiles.

What is a Fixture?

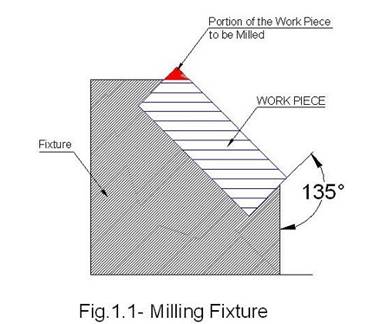

The

fixture is a tool which holds the workpiece with the machine bed precisely at

the desired location. The fixture also reduces the nonproductive loading,

unloading, and fixing time of the workpiece. For example, you need to use a

milling machine for giving a chamfer at the corner of rectangular work pieces.

You can use a vice to hold it in the desired position, but in that case every

new work piece will take lots of time for fixing it. On the other hand if you

can make a milling fixture like the one shown below and bolt the fixture to the

milling machine bed, then you need not waste much time for fixing the work

pieces every time:

You just

place the workpiece and it will automatically aligned to the required angle,

and straight away you run the machining operation, no need to measure the

angle, and no need to be worried about the accuracy.

Conclusion

Both the

jigs and the fixtures are used to reduce the nonproductive time of

any mass production process. The principle of location or the 3-2-1

principle, CAD tools (like ProE), and FEA tools

(like ANSYS) are used for the design of the jigs as well the fixtures. The

jig is used for guiding the cutting tool (like a drill bit), and for doing so,

jigs have components like a bush, which comes in contact with the cutting tool.

On the other hand, a fixture never comes in direct contact with the cutting

tool. Fixtures assure the position and alignment of the work pieces for getting

the required machining operation done.