Introduction:

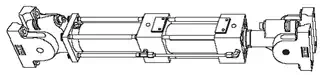

Linear actuators are mechanical devices that convert the energy as extraction of power from air or electricity from liquids, in order to create motion in a straight line that is contrasted with a circular motion of the electric motor.

These linear actuators move the work tables that are on the industrial machines, modulation of control valves, material handling equipment, robotic and any computer equipment. These are also used for the force application. Several movements can be done with this equipment that includes blocking, clamping, ejecting, descending, pulling or pushing. They are used to drive shovels and lifts in the construction equipment that provides easy oscillations.

Basic principle of working:

The main principle involved in their operation is an inclined plane. The threads of a lead screw acts as continues ramp that allows the small rotational forces that are to be used over long distances in order to accomplish movement of a large load over a very short distance.

How do they work?

The external and the non-linear forces are the dependants of actuators to drive the piston back and forth movements, still different linear actuators works in different ways. This piston is a sliding piece that is actually moved with or against fluid, air pressure or electricity. It is generally fitted with a short cylinder within a cylinder vessel.

- In steam engines the motion is created by steam and motion of fluid that pumps transmit.

- In hydraulic pumps the actuators mechanism dependent on the hydraulic pump in order to compress and decompress the available two sides of a piston to have back and forth motion. A shaft is attached to the piston that is responsible for the shaft movement.

- The wax motor linear actuators use electric current to melt the wax blocks which are main cause for the expansion. This wax expands and contracts with the varying electrical currents i.e. a plunger which is pressed against it moves back and forth in a linear motion.

Power and operational options:

There are many available linear actuators with more force options. Lead screw systems of the clamps and vices, levers that are found in the manual juicers or the can crushers are the manual mechanical methods. The cylinders with pistons are powered by the air that is compressed and is used to move the machine parts. The pistons in the hydraulic cylinders provide very large strokes and forces for the construction equipment as shovels, jacks and lifts. The short throw cylinders for the braking systems are also included in them. The solenoid coils that are short throw electromagnetic linear actuators will turn switches and valves to ON and OFF along with lock and unlock of the car doors. The linear progressions of the electromagnetic motor poles are used for the people movers, trams and the material conveyors.

Static and dynamic linear actuators:

Screw type linear actuators can have a static loading capacity that means the motor stops will have actuators with essential locks in order to provide support to pull or push the actuator. The acme screws will have very high static loading capacities that have extremely low load capacity.

The dynamic loads are used in some specific designs that are added with screw type linear actuators using the electromagnetic brake system that is used to apply braking friction to the driving nut. The actuator uses an electro magnet counter acts of the spring and this release braking forces. The thread pitch of the screw and the design of the nut will be a linear actuator to define the specific load capacity that may not be adjusted dynamically.

Applications:

- These are used in industrial automation mostly in machine tools, peripherals of computers as disk drivers along with printers.

- Home automation, manufacturing using electronic technology, laser processing and storage devices.

- Linear actuators are used in valves, motors, switches, pumps, medical imaging, solar, farming, and automotive plus other robotic applications.

- The electronic devices that require linear motion uses these linear actuators. Power pumps, power drills and many other industrial applications use these actuators.

- In robotic industry these are used for the fuel injection with linear motion.