How to Design a Compression Valve Spring

The valve springs are a critical component for any engine’s performance. This article will talk about how to design a valve spring.

What is Valve Spring?

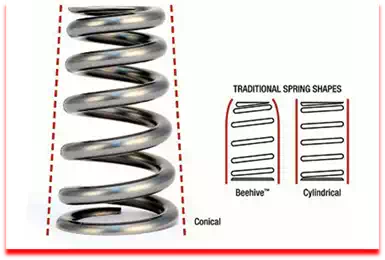

● A valve spring is a compression type spring that is kept around a valve stem and retained by a part called a retainer. The length of valve movement, called lift distance, determines how much the spring will be compressed. An external force on the valve spring opens the valves and the springs get compressed.

Essential Equations for Compression Spring Design Calculation

● The following equations (apart from some basic equations) will be used for designing or selecting a valve compression spring:

Relation between the applied external force and generated maximum shear stress in the wire:

● Tmax=W*(8FD)/(pi*d^3)……eqn.1

● Where, Tmax is maximum shear stress generated in wire

● W is Wahl correction factor

● F is applied external force

● D Nominal diameter of the spring coil

● d is wire diameter of the spring

● Further, W can be calculated as

● W= (4C-1)/ (4C-4) + (0.615/C)…..eqn.2

● Where, C is spring index [i.e. ratio of spring wire diameter (d) to nominal spring diameter (D)]

Relation between number of active coils and spring constant:

● Na= (G*d^4)/ (8*D^3*K)……….eqn.3

● Where, Na is required number of active coil

● G is shear modulus of the spring material.

● d is spring wire diameter

● D is nominal diameter of spring

● K is spring constant

Steps for Valve Compression Spring Design

● The equations explained above should be used in the following order to get a valve spring design solution. Alternatively, you can use compression spring design calculator that is available on the Internet.

○ Typically, you would get the following data as input for valve spring design:

● 1. Either applied external force (F) or maximum generated shear stress in spring wire (Tmax).

● 2. Value of compression (delta) under externally applied force.

● 3. Any two values among spring wire diameter (d), nominal spring diameter (D) and spring index (C).

● 4. Shear modulus of the spring material (G)

○ Use eqn.2 for calculating Wahl correction factor (W).

○ Use eqn.1 and find out unknown of F and Tmax.

○ Calculate valve spring stiffness (K) using the equation F=K*delta.

○ Use eqn.3 for calculating required number of spring coil (Na).