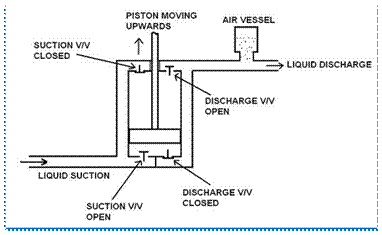

Air Vessels

Air vessel is a closed chamber containing compressed air in the top portion and liquid (or water) at the bottom of the chamber. At the base of the chamber, there is an opening through which the liquid (or water) may flow into the vessel or out from the vessel. When the liquid enters the air vessel, the air gets compressed further and when liquid flows out the vessel, the air will expand in the chamber. An air vessel is fitted to the suction pipe and to the delivery pipe at the point close to the cylinder of a single-acting reciprocating pump.

The Air vessels are used for the following purposes:

(a) To get continuous supply of liquid at a uniform

rate.

(b) To save the power required to drive the pump.

This is due to the fact that by using air vessels, the acceleration and

friction heads are reduced. Thus the work is also reduced.

It may be noted that by fitting an air vessel to the

reciprocating pump, the saving of work and subsequently the power is about 84.8

% in case of a single acting reciprocating pump and 39.2 % in case of double

acting reciprocating pump.