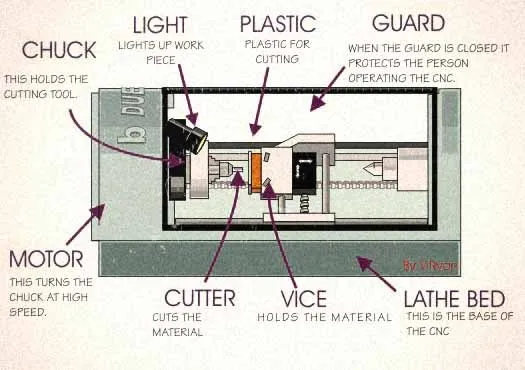

The control and movement of the lathe machines can be done with the help of computers. The function of the lathe machine actuated by the Computer Numerical Controls (CNC) is known as CNC lathe. Have a look at the figure for a clear idea –

Vice: Vice is actually like a clamp which holds the job. At the time of machining the material must be held tightly otherwise it will shake or vibrate and can fly out which can cause serious damage. So the main function of the vice is to hold the material in the perfect position for cutting and shaping.

Guard: The guard provides protection to the CNC machine operator. The guide keeps the dangerous areas enclosed with some kind of barrier. Dangerous area means the spaces from where chips can be shoot and head towards the machine operator.

Chuck: This part holds the material that is needed to be shaped or cut. Materials should be fastened to the chuck with care otherwise the material can fly out of the chuck causing damage. Sometimes chucks are used to hold the cutting tool.

Motor: The motor is the main mover in the CNC lathe. This devise rotates the chuck of the CNC.

Lathe Bed: It is the base of the lathe machine. Usually CNC machines use special foundation for making the machine stationary so that the lathe bed doesn’t move or vibrate.

Cutting Tool: Very high quality steel is used to make the cutting tools. Different types of cutting tools are used to shape the material.

· It can work continuously all over the year. It can be run 24 hours a day for 365 days! It needs some periodic maintenance for a short period of time.

· CNC machines can thousands of products having same shape and similar dimensions. Once the machine is programmed with the design it can produce tons of products without any deviation from the design.

· CNC machines doesn’t need skilled workers. Less trained people can operate the machine.

· Improved software can update the machine output.

· Virtual software can provide the training of the operator which helps him while running the machine in real life.

· Modern design software can be incorporated with the CNC to make precise products.

· There is no need to make prototypes. A company can go to direct production if they have CNC machines.

· It works automatically so no need for huge man power or money to run the machine.

· CNC lathes are very expensive then the conventional manual lathes.

· The operation of the CNC lathes is very simple. There isn’t any need of skilled personnel to run the machine. As a result engineers are reluctant to learn the basic machining operations.

· Very few people are needed to run a CNC machine. On the other hand manual lathes always needs an operator to complete the job. Expansion of CNC technology can cause unemployment.