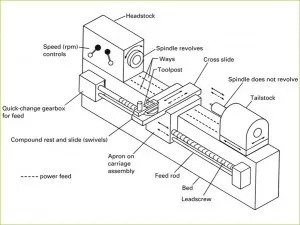

In lathe machine a rotating workpiece is held between the rigid supports while a stationery tool is used to cut the workpiece to give the desired shape. It is very important machine for metal cutting. Different parts of lathe machine are needed to be known to conduct the machining work perfectly. So lets discuss in details –

Bed: It is the part where different operational parts of the lathe machine is mounted. Generally it is single piece cast product made of hardened steel. If the lathe machine is large in size then the bed can consist of more than a single piece. Beds are heavy in construction that’s the reason it can damp all the vibrations that occur while machining. The guides or slide ways are present on the bed for guiding the other parts like tail stock etc. The bed supports all other major components.

Carriage: It contains cross-slide, apron and cross slide, compound rest , saddle etc. It supports the tool and guides it along the desired direction for perfect feed.

Headstock – It works as a housing for the driving pulleys and gears. It is located at the left side of the lathe machine. It provides various drive speeds. Headstock holds the jaws and supplies power .

Tailstock – Tailstock is used for supporting the workpiece from the other side. Tailstocks can slide along the bed. It is an important lathe machine component.

Feed Rod and Lead Screw-Feed – Feed rod and lead screw almost serve the same purpose. Feed rod is used for basic turning. But lead screw is used for threading.

Lets discuss the assemblies of the most important lathe parts.

Bed – Beds are made of grey cast iron and used for vibration damping.

Headstock assembly – It consists of spindle, transmission and drive motor.

Tailstock assembly – The assembly of tailstock involves longitudinal way clamp, transverse way clamp and quill for cutting tools, live centers or dead centers.

Carriage Assembly

It includes cross slide, helps to hold the tool post at different orientations . It can provide longitudinal as well as transverse movement.

Quick-change gearbox

It provides power to the carriage assembly. It works along with the lead screw.

Ways

Guides the carriage and tailstock to perfect direction.

n this article we will discuss about the different types of lathe machines. The four main types of lathes are

· Speed Lathes

· Engine Lathes

· Tool Room Lathes and

· Turret Lathes

So let’s start .

It is very simple is design. It only has headstock, tailstock and a very simple tool post. It can operate in 3-4 speeds. The spindle speed is very high. It is used for light machine works like wood turning, metal spinning and metal polishing.

Engine lathes are the most common types of lathe machine. It is designed for low power operations as well as high power operations. Various lengths of the machine is available. The length can be up to 60 feet. Engine lathe is commonly seen in every machine shop. Various metals can be machines. The machine can operates at a wide range of speed ratios.

It is a very versatile lathe machine. It can give better accuracy and finishing . It has wider range of speeds . It can give different types of feeds. It can be a great device to manufacture die.

It is a great machine for quick operations. It has various types of tool posts mounted on a single structure. As a number of tools are set up on machine, the job can be completed very quickly with the help of a single setup. A capstan wheel is used to position the next tool. A sequential machining process can be done by using the turret lathe without moving the workpiece. It eliminates the error that occurs due to misalignment.

These are the machines which are allows the worker to perform tasks which are not possible in normal lathe machines. These lathes include –

· bench type jeweler’s lathe

· Automatic lathes

· brakedrum lathes

· multispindle lathes

· crankshaft lathes

· duplicating lathes