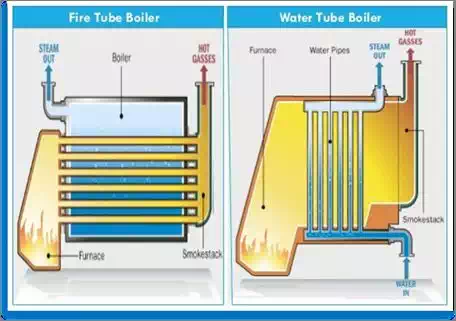

Comparison Between Fire Tube and Water Tube Boiler

Comparison between Fire Tube and Water Tube Boiler can be done in 14 aspects. Those aspects are operating pressure, passage of material type in tubes, rate of steam generation, handling of load fluctuation, floor area requirement, efficiency, operator skills, design, maintenance cost are listed below in the tabular form.

S.No | Fire tube boiler | Water tube boiler |

1 | In Fire-tube boilers hot flue gases pass through tubes and water surrounds them. | In Water-tube boilers water passes through tubes and hot flue gasses surround them. |

2 | These are operated at low pressures up to 20 bar. | The working pressure is high enough, up to 250 bar in super critical boilers. |

3 | The rate of steam generation and quality of steam are very low, therefore, not suitable for power generation. | The rate of steam generation and quality of steam are better and suitable for power generation. |

4 | Load fluctuations cannot be handled. | Load fluctuations can be easily handled. |

5 | It requires more floor area for a given output. | It requires less floor area for a given output |

6 | These are bulky and difficult to transport. | These are light in weight, hence transportation is not a problem. |

7 | Overall efficiency is up to 75%. | Overall efficiency with an economizer is up to 90%. |

8 | Water doesn’t circulate in a definite direction. | Direction of water circulated is well defined. |

9 | The drum size is large and damage caused by bursting is large. | If any water tube is damaged, it can be easily replaced or repaired. |

10 | It requires more floor area for a given output. | It requires less floor area for a given output |

11 | Simple in design, easy to erect and low maintenance cost. | Complex, design, difficult to erect and high maintenance cost. |

12 | Even less skill operators are sufficient for efficient operation. | Skilled operators are required for operation. |

13 | The treatment of feed water is not very essential, as overheating due to scale formation cannot burst thick shell. | Treatment of feed water is very essential as small scale deposits inside the tubes can cause overheating and bursting. |

14 | Used in process industry. | Used in large power plants. |