Aircraft Hydraulic Engineers

An aircraft's hydraulic systems are among the most vital components for ensuring a safe flight. The hydraulic systems include the landing gear control, flying control surfaces, wing control, wheel steering and many other sub-systems.

The generation of hydraulic pressure is made through hydraulic pumps, reservoirs, fluids, pipes, valves and other components, and it is converted into control surface movement with the aid of actuators. The flying control surfaces (ailerons, rudder and elevator) are used for the aircraft's navigation.

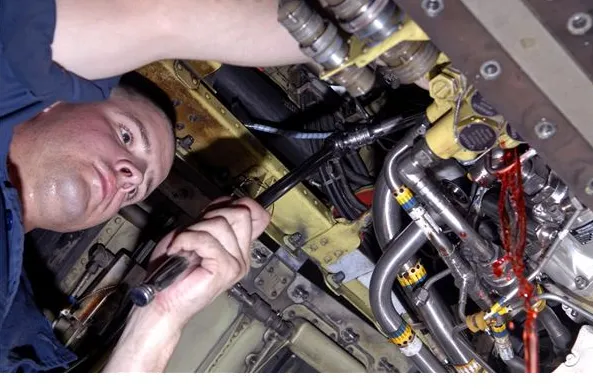

The aircraft hydraulic engineer plays an important role by maintaining these systems in perfect condition according to technical standards and procedures. He can be employed by civil aviation companies or companies specialized in the aircraft maintenance field and construction (aircraft plants). Another option is to provide military service.

Qualifications – Skills – Competences

The basic requirements for following an aircraft hydraulics engineering career are the following:

· Basic high school education

· Technical training and certification. Completion of military training courses (e.g. US Air Force Base ) or training obtained through civil authorities and organizations or companies.

· Practical and theoretical knowledge of the aircraft's hydraulics, pneudraulics and other associated systems (electrical and mechanical), refueling procedures, checking controls etc.

· Be physically and mentally fit

· Ability to work quickly and accurately under pressure and difficult conditions

· Team spirit and collaborative skills

· Diligence, self-discipline and strong sense of responsibility

Responsibilities

The aircraft hydraulics engineer is generally responsible for maintaining all the hydraulics sub-systems and components in perfect condition. More specifically, he is in charge of installing and inspecting the pneumatic and hydraulic systems, removing, repairing and replacing any components that don't work properly or according to the accepted performance standards. He should be able to perform regular system operation checks and take corrective action in case of any malfunction. After the necessary checks are completed, he prepares and signs a report to certify that the systems work in excellent condition and they conform to the technical standards.

Among other obligations, he should be able to perform his duties without any assistance in difficult situations, work efficiently within the team and take directions from the chief engineer to ensure maximum performance. Since, he is in daily contact with high technology systems, constant training is absolutely to keep up with the design modifications and advances.

Working Conditions

The profession of the Aircraft Hydraulic Engineer demands a strong sense of responsibility and dedication. The engineer will have to perform both line and base checking activities. The first one involves pre-flight checks performed on the airfield between the flights, often under a tight schedule. The second involves more thorough checks and repairs performed in the hangar, after the aircraft has completed a certain number of flight hours. The demands are high since engineers don't have regular working hours and are sometimes required to work under harsh weather conditions. An engineer may also have to work alone or in cooperation with other colleagues,engineers, technicians etc. and in many occasions travel abroad to fulfill his duties.

Plenty of vacancies seem to be available for aircraft pneudraulic and hydraulic system technicians and assistants internationally. Many of the jobs are available online on sites like www.aviationrecruiting.net and www.engineer-jobs.com . An important thing for an applicant to remember, is that most of them require flexible working hours and the ability to travel often.

Aircraft Hydraulics Systems