Secondary Combustion Systems for Wood Stoves

Heat emitting from burning wood can be extracted in two ways. The primary combustion of wood is what we see when wood is set alight and a flame starts. The heat extracted from this flame is what many barbecue enthusiasts may be all too familiar with. However, combustible seasoned wood offers additional source of heat energy. In most cases, such as the one of your Sunday afternoon barbecue enthusiast, this heat is allowed to escape. With secondary combustion systems for wood stoves, this secondary heat can be used to add additional heat energy to the primary heat.

Clear benefits of secondary combustion are increased heat output with less wood, lower emissions, and decreased creosote formation.

How Secondary Combustion in a Woodstove Works

In most current day production wood stoves, a baffle plate can be located between the flue outlet and the fire chamber. It is here where secondary combustion occurs. A baffle plate creates a pressurized system for efficient flow rate and distribution throughout the system. In other wood stove models, the presence of a baffle plate can be replaced by a ceramic honeycomb. Both serve as catalysts to the combustion process. Their core function is to filter the combustion smoke making it pollution free.

The ignition of secondary gases may cause the temperature to increase anywhere from 450 to 1600 degrees Fahrenheit.

Phenomenal temperatures such as these, though, can create a type of vacuum within the stove which in turn could cause the wood to burn as fast as what the increased temperature demands. This effect can be counteracted by a small intake hole providing oxygen to the stove. The oxygen supply enables the burning wood to burn for longer periods.

In a normal stove, a fire burning at its optimum causes a draft which forces the air away from the fire. As can be imagined, the potential heat is then redirected up the chimney (as hot air rises). Ideally, a chemical reaction needs to occur in two or more steps. Heat inefficiency occurs when the second step cannot take place. The byproduct of this inefficiency results in creosote deposits on your chimney. The two steps can be listed as follows:

1. Carbon plus Oxygen gives Carbon Monoxide

2. Carbon Monoxide plus Oxygen gives Carbon Dioxide

· In a secondary combustion wood stove system, optimum efficiency from your wood fire would result in the optimum occurrence of both steps of the chemical reaction. The baffle plate or ceramic honeycomb function as catalytic converters which process the escaping heat as additional heat for the combustion process. Creosote is the combustible byproduct of inefficient combustion that usually gathers in chimneys and pipe outlets stemming from the fire place.

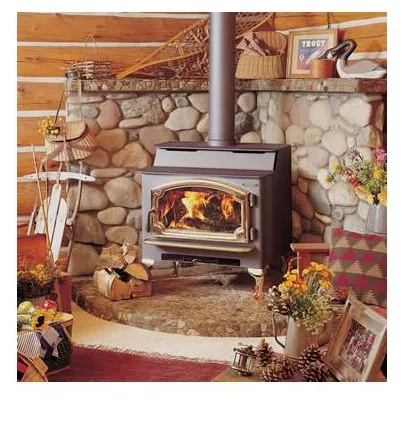

· One practical method of eliminating the formation of creosote is to turn the draft control on your wood stove down. Although this increases wood burn time while simultaneously creating additional heat, caution needs to be taken to ensure the fire does not smolder. If your wood stove has a viewing window, you would easily identify when the fire is being starved of oxygen as it would probably go out. If you do not have a viewing window, you can attach a flue gas thermometer approximately 20 inches above the stove and ensure that the temperature always remains above 325 degrees.