How Intake Resonators improve Volumetric Efficiency

The volumetric efficiency and resonators in an air intake system are two closely related terms for the performance of naturally aspirated internal combustion engines. This article will discuss Helmholtz resonator designs and how intake resonators work.

The intake manifolds of modern naturally aspirated IC engines are integrated with resonators. The purpose of the Helmholtz resonator is to improve the volumetric efficiency of the engine and also to help with engine sound attenuation. This is possible due to the special features of the Helmholtz resonator designs.

What is the Volumetric Efficiency of an IC Engine?

The volumetric efficiency of an IC engine is the ratio of the volume of air fuel mixture (or air) entered into the combustion cylinder to the volume of the cylinder when the piston is at bottom dead center. The volumetric efficiency is directly related to the torque output of the engine. Turbocharged engines can easily achieve a volumetric efficiency over 100%. For naturally aspirated engines, higher volumetric efficiency is achieved by using resonators integrated with the inlet manifold design.

Basics about Helmholtz Resonator Designs

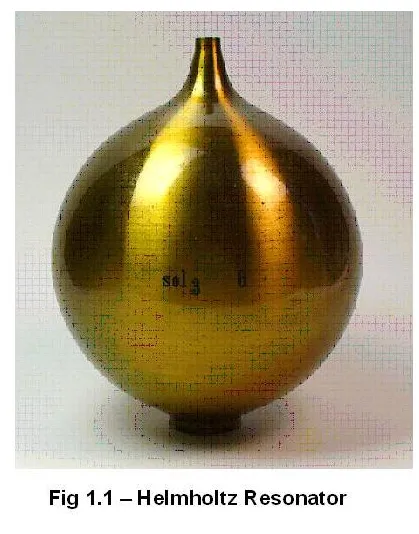

The designs of Helmholtz resonator (or only resonator) is characterized by the large cavity at its belly and a thin neck. See the picture below:

It basically works on the theory of harmony. As the air (or any gas) tries to ram into the resonator through its neck, the pressure inside the cavity increases and the air bounces out, but while bouncing out quickly due to inertia, it creates a partial vacuum near the neck of the resonator and the air is again sucked in. The process continues like the phenomena of a ping-pong ball hitting the ground. The resonator acts like a shock absorber for the pressure waves.

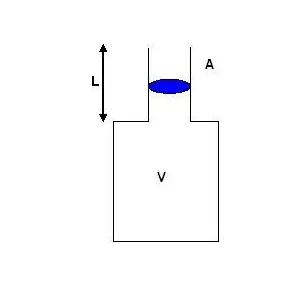

The frequency of a resonator can be calculated as below:

Frequency f = (c/2Π).√ (A/L.V)

Where,

c = the speed of sound.

L = length of the neck

A = area of the neck

V = cavity volume of the resonator

How the Resonator can improve Volumetric Efficiency

· In an IC engine, air or the air-fuel mixture is sucked inside the cylinder while the piston is moving toward bottom dead centre (BDC).

· As the filling process progresses, the charge air gains more and more momentum, so the speed of the charge air increases gradually.

· As soon as the piston reaches BDC, suddenly the inlet valve closes. But, the air in the intake manifold still has a substantial amount of velocity (or dynamic pressure).

Conclusion

This article discussed the relation between IC engine volumetric efficiency and resonators in air intake system. The volumetric efficiency of an IC engine can be increased by using the resonators provided they are properly tuned. While tuning the system, the volume and the design of the inlet manifold also need to be considered because the air inside the intake manifold will also participate in resonance.