The Benefits of Parametric Modeling & The Sensitivity Study

Anyone who uses a finite element analysis tool will tell you that there is nothing more exciting than starting a brand new model. It’s the thrill of the unknown. The solution is out there and all you need to figure out how to find it. Answering questions like how much detail is required? What loads do I need? and How am I going to get this darn thing to converge?, are what being an engineer is all about.

So you dive into the process, spending the next few hours, (or days, or months) living on coffee, forgoing sleep, nutrition, social interaction, and sometimes personal hygiene, until the answer is at your fingertips. This is typically followed by a let-down period as you sit stoically waiting for the next engineering challenge to pass your way. But, there is a fate worse than this idle down- time to the engineer. Rather than a new problem, the engineer is asked to perform a “sensitivity study”.

The hard cold reality of today’s design environment is that products need to be stronger, lighter, cheaper, and brought to market ahead of the competition. The luxury of big safety factors and margins on our designs are a thing of the past. We have to cut it much closer now with the certainty that the design is robust regardless of tolerances in the manufacturing process, the material lot, and the design loads. We need to perform sensitivity studies on our designs.

Just the phrase “sensitivity study” is in contrast to our engineering selves. (Not many of us are known for our sensitive sides.) In the product design arena, sensitivity studies require that we dig more deeply into a problem that we have already solved. They often require reworking a model where the thrill of discovery is long gone. Modeling becomes drudgery, repetitive, a “process”. It’s a living death for the engineer. And think about how our managers feel. Engineers can be ferocious creatures of habit. Getting us to adopt a new method not of our own choosing can be a daunting task.

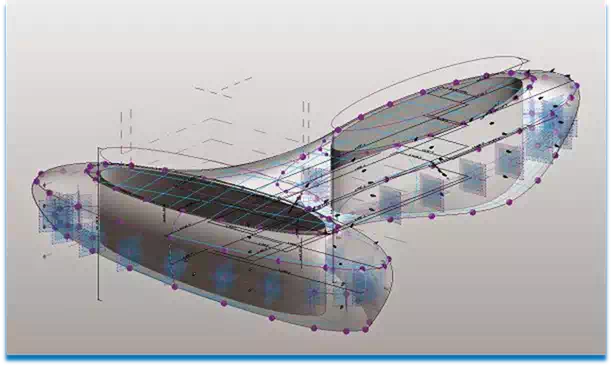

However, it doesn’t have to be that way. We are all using CAD models in the design process which are inherently parametric and can be stretched and twisted and altered like electronic silly putty at the click of a button. By linking the response of the finite element model to alterations in the geometry we can introduce into the sensitivity study a term that no engineer can resist: automation!

So now this sensitivity study thing is starting to look pretty good, because it presents a challenge in place of a repetitive task. How can we take advantage of the parametric nature of the geometry to evaluate the effect on the end result? And why stop there? Let’s look at what happens when we vary the material coefficients and loads. Let’s automate the mesh convergence part of the analysis and link the mesh settings to the geometry for consistency.

Setting up the model still has all the thrill of discovery with the added benefit of determining which variables play a dominant role in the response. Design tables can be entered manually or generated automatically using your favorite algorithm. The responses can be plotted and charted in a variety of ways. A whole new challenge of determining the “best” design within the parameter space is born. Managers can use this challenge as a way to convince their design engineers to embrace the sensitivity study. As one managerial clairvoyant once said, “We can howl at the edge of the forest all day long, but we’re not going to get any Bigfoots to come out unless we fry up some bacon”. So come on fellow missing links, let’s fire up those CAD and analysis tools and bring home the bacon!