Working of Manual Transmission

When you start a manual transmission car, before you turn the key, you disengage the clutch by pressing down on the clutch pedal. This disconnects power flow between the engineís input shaft and transmission. This allows your engine to run without delivering power to the rest of the vehicle.

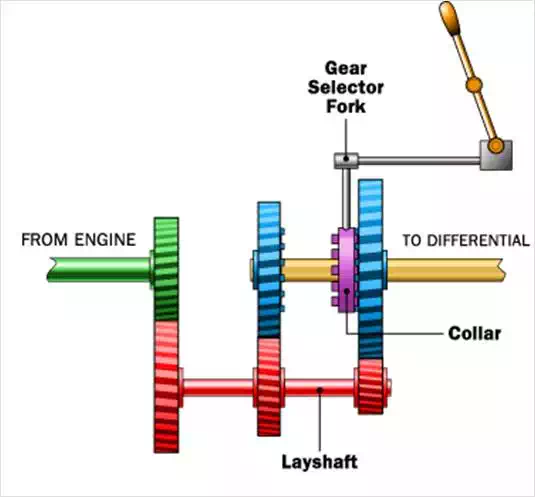

With the clutch disengaged, you move the gearshift into first gear. This causes a shifting rod in your transmissionís gearbox to move the shifting fork towards first gear, which is mounted to the output shaft via ball bearings.

This first gear on the output shaft is enmeshed with a gear thatís connected to a countershaft. The countershaft connects to the engineís input shaft via a gear and spins at the same speed as the engineís input shaft.

Attached to the shifting fork is a synchronizer collar. The synchronizer collar does two things: 1) it firmly mounts the driving gear to the output shaft so the gear can deliver power to the output shaft, and 2) it ensures that the gear syncs up with the speed of the output shaft.

Once the synchronizer collar is enmeshed with the first gear, the gear is firmly connected to the output shaft, and the vehicle is now in gear. the first gear is large, it causes the output shaft to spin more slowly than the engineís input shaft, but deliver more power to the rest of the drivetrain. This is thanks to the wonders of gear ratios.

To increase the speed of the output shaft, we need to shift up to second gear. So we step on the clutch to disconnect power between the engine and transmission gearbox and shift into second gear. This moves the shifting rod that has a shift fork and synchronizer collar towards second gear. The synchronizer collar syncs up the second gearís speed with the output shaft and firmly mounts it to the output shaft. The output shaft can now spin faster without the engineís input shaft spinning furiously to produce the power the car needs. For the rest of the five gears, itís rinse, wash, and repeat.