Pressure Regulatory Mechanism in Inert Gas (IG) Systems on Ships

Pressure in the Inert Gas (IG) system needs to be maintained within an ideal value – neither too high nor too low. Learn why is this necessary and how is this achieved on board ships.

Introduction

We saw the design considerations required for the piping and valves on the IG systems used on board ships. In this article we will learn about the pressure regulating mechanisms incorporated in the IG system and their uses.

Need for Pressure Regulating Mechanism

You might think that the inert gas delivery system does not involve very high pressures to what is the point of having all these extra paraphernalia on the system. The answer to this question is that though the IG system may not be handling pressures of a huge magnitude it is the safety consideration which necessitates the incorporation of these devices. Basically there are two main functions which these devices need to perform in the IG system. Firstly they need to ensure that there is only one way flow of gases from the IG plant to the IG distribution system across the cargo gas barriers (click here if you have forgotten the layout of the IG system). Such a blowback could occur if the deck water seal fails or the IG plant develops some kind of a technical snag. Secondly even if all systems are working perfectly fine, there might be a need to control the rate of flow of inert gases to the tanks.

How is Regulation Achieved?

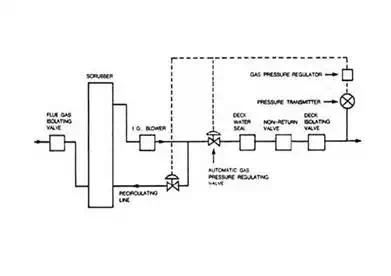

There are two ways in which the pressure in the distribution system can be manipulated. It could either be done through variable speed of the inert gas blowers which is a crude way of doing it and the other is to have pressure regulating valves which is a modern technique. The latter is shown in the diagram below which shows an arrangement for pressure regulation using automatic valves and a recirculating line.

The operation of the system is quite simple. The pressure transmitter senses and transmits the pressure signal to the regulator which in turn controls either one or both of the regulating valves located on the main inlet line and the recirculation line respectively thus taking care of any pressure variations in the desired direction. In case of simpler systems the automatic pressure regulating valves may not have the hi-tech regulatory mechanism shown here but simply be operated by weight. This principle is similar to the one utilized to maintain adequate pressure inside the pressure cooker used in kitchens. When the pressure is too low the valve is shut and keeps it inside while if it rises above a certain value which is adjusted using the weight on the outlet, the excess pressure gets relieved thus leaving only an optimum pressure inside the vessel. Similarly in the case of IG systems on ships it is ensured that under ideal conditions there is a positive pressure with respect to atmosphere so that there is no ingression of air in the system which could lead towards a region within the flammable triangle in the flammability graph. Any pressure in excess of that positive pressure also could be dangerous and needs to be relieved to the atmosphere using safety valves.