Distilled Water Treatment On Board Ships

Learn about the reasons for treating distilled water, as well methods of sterilization.

It is a general practice to generate freshwater from seawater onboard for domestic purposes. On an average the crew consumes about 70 litres/person/day (in case of passenger ships, 225 l/person/day). Usually we used to take only a minimum quantity of fresh water from the port for domestic services (since we are not allowed to use the freshwater generator in port).

At sea we used to generate freshwater from seawater by two methods.

1. Reverse osmosis (in brief called R.O.)

2. Low pressure Evaporators

Usually the jacket cooling water from the main engine is used so that the heat taken from the engine is utilised ( this is in case of a low pressure evaporator)

Reasons for treating the distillate

· The temperature of the jacket cooling water entering the freshwater generator is around 75-80°c. So the low operating temperature inside the evaporator cannot sterilize the distillate properly, as some of the germs and harmful organisms are killed only at 100°c and hence the distillate has to be treated.

· There are chances of the water becoming infested with the bacteria due to colonial organisms. Sterilization by the addition of chlorine and electro-katadyn process is recommended in Merchant Shipping Notices M1214 and M1401 respectively.

· The distilled water has none of the dissolved solids in common that is present in freshwater and also it has no taste (ie, it tastes flat).

· Distilled water tends to be slightly acidic as it absorbs co2 readily. This condition will cause problems like corrosion, and the human digestive tract will be disturbed.

Some of the methods incorporated to avoid the above problems are :

· Chlorine sterilization

· Electro-Katadyn method

· Ultraviolet sterilizer

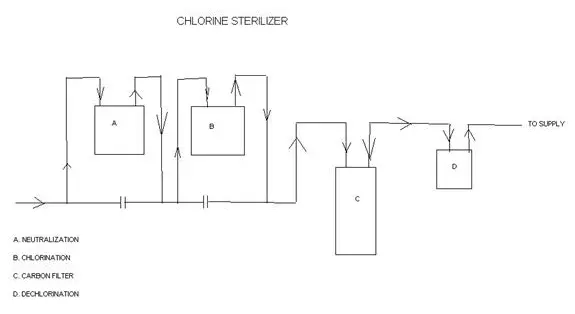

Chlorine sterilization

Distilled water (the distillate) passes initially through a neutralizing unit which contains magnesium and calcium carbonate. Here the carbon dioxide will be removed (to avoid acidity). The addition of hardness salts gives taste to water. Now water passes through the sterilizing unit which contains a sterilizing agent. This agent (chlorine) is carried either as constituent of sodium hypochlorite (liquid) or as granules of calcium chloride dissolved in water to bring chlorine content to about 0.2ppm. The distillate is then taken through carbon filter and dechlorination unit containing calciumcarbonate to remove chlorine taste from the water.

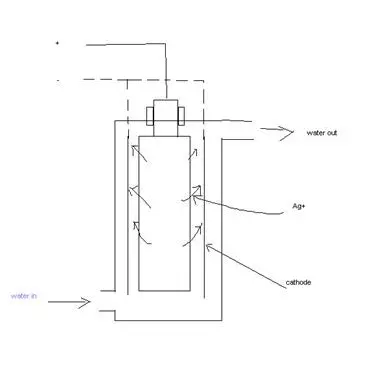

Electro-katadyn method

This method can be used as an alternative to chlorination. In this method silver anode is used. Silver being toxic to various risky and harmful organisms remains in the water. The silver anode gives out silver ions according to the current setting.

We can consider two cases. One when large quantity of water has to be treated and another in which a small quantity to be treated.

· In the first case: Only a part of water is bypassed to the unit. Here a high current setting is used so that large amount of silver ions are injected to the water and the bypassed water is then mixed with the rest of the water.

· In the second case: For treating low quantities of water the low current setting is used and the whole quantity of water is passed through the unit (ie no water is bypassed).

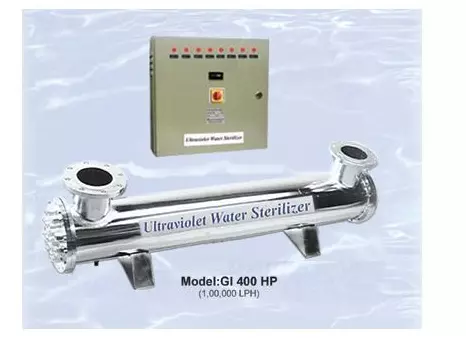

Ultraviolet sterilizer

This unit is fitted in between the hydrophore tanks and the supply points(tap). The stainless steel irradiation chamber consists of low pressure mercury vapour tubes placed in a quartz jacket. The ultraviolet radiation provided by the mercury vapour is used to kill all the bacteria, viruses and any other harmful organisms which are not trapped by the filter. It consists of a cylindrical tube having one inlet and outlet for water so that the water is sterilized as it passes through.