Ballast Free Ship Design

Introduction:

Ballast water is fresh or seawater, held in tanks and cargo holds of ships to increase stability and manoeuvrability during transit. Ballast water is essential to the safe and efficient operation of modern ships, providing balance and stability to un-laden ships (often returning empty during return voyages) as well as loaded ships. Its superb operational advantages, however come at a cost.

It poses serious ecological and health threats due to transfer of a multitude of marine species (non- native species) into an altogether different host environment containing different native species.

Didn’t quite get that?

e.g.- The ballast water is taken from coastal port areas(source point) and transported inside the ship to the next port of call(destination point) where it may be discharged, along with all the surviving organisms. This way, the ballast water may introduce organisms into the port of discharge which do not naturally belong there. These introduced species are called exotic species. Populations of exotic species may grow very quickly in the absence of natural predators. In this case they are called ‘invasive’. However, most species can’t survive in the new surroundings – temperature, salinity etc. (Remember, Survival of the fittest?) being less than optimal. Thus only a few species are ‘successful invaders’, however those that do survive, establish a population and have the potential to cause major harm! Aquatic invasions are considered the second greatest threat to global bio-diversity after habitat loss, are virtually irreversible, and increase in severity over time. If that is the case, then one can’t even imagine the damage, caused by transfer of 3 to 5 billion tons of ballast water each year.

SOLUTIONS:

NO BALLAST SHIP (NOBS) CONCEPTS:

There are mainly three projects in which the concept of a ship with zero ballast water has been developed:

· Delft University of Technology (DUT)-‘Monomaran Hull’.

· Det Norske Veritas(DNV)-‘Volume Cargo Ship’

· Daewoo Shipbuilding and Marine Engineering(DSME)-‘ Solid Ballast Ship’

1. ‘The Monomaran Hull’ – An unloaded rolling ship (without ballast water) requires adequate stability. DUT proposed a monomaran hull by adopting a catamaran shape to the base of the broad single hull.

2. ‘Volume Cargo Ship’ - DNV proposed a design similar to DUT but with a trimaran hull shape thus imparting high level of stability.

3. ‘Solid ballast ship’ – In this case, the ballast water is replaced by 25 tonne Solid ballast in standard containers. However the application of this method is limited to container ships only. The hull form (size) remains the same.

Another solution to this problem is the Yokohama buoyancy control compartment concept, which converts conventional ballast tanks into a series of buoyancy control compartments.

|

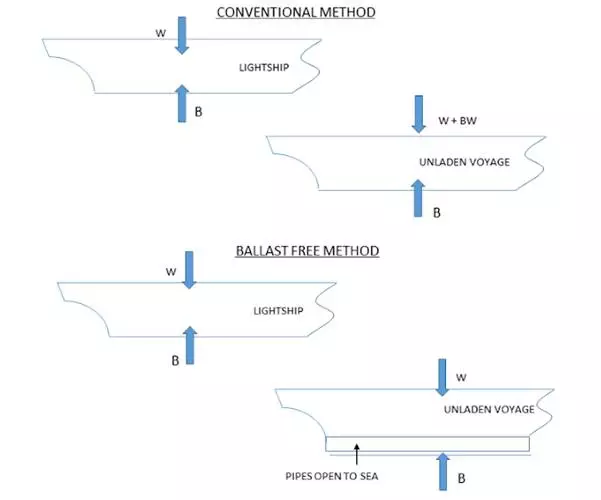

(Fig. 1: Comparison between conventional ballasting and ballast free ship design. (Courtesy: www.nsdrc.com/Publications-"Development of a ballast free ship design" by Avinash Godey, Prof. S.C. Misra, Prof. O.P. Sha) |

Each compartment is flooded to provide adequate draught in the unloaded

condition then continuously flushed at normal voyage speeds to ensure efficient

exchange without the need for pumps. Each compartment is fitted with intake and

outlet valves that are optimally designed and positioned for each compartment

so as to maximize its flushing rate during normal voyage speeds.

Although ballast water treatment is an effective way of tackling ballast water issues.