Stiffening And Stiffeners

The word 'stiffening' essentially suggests the purpose of providing extra

stress-bearing capacity or rigidity to the existing structural

member.

Does simply erecting four successive plates in a mid-ship section, for instance serve the purpose?

The answer is a big no. Every structural member

requires a stiffening in some form not only to be stable itself, but also to

provide resistance to the various amount of internal and external causal agents

leading to stress concentrations on the structure. These stress concentrations

as you know are fatal, even if neglected once! Thus stiffening from grass root

level is of utmost mandate for every single component irrespective of size,

location, form and purpose. Stiffeners are these secondary structural

components which conjoin with the principal members giving rise to the complete

framework of stiffened panels.These panels in unison all throughout the

designated length, beam and depth form the final structure of the ship's hull.

The stiffeners also have their own classification:

· Longitudinal Stiffeners: As the name suggests, they provide longitudinal stiffening,viz., retain the rigidity against the longitudinal bending and buckling of the ship. As the waves in the open seas are unpredictable and maybe sometimes highly precarious, failure. Longitudinal stiffening mainly focuses on the length-wise stiffening parallel to the center line. The primary objective running through the mind of all designers and naval architects are the basic concepts of shear force and the resultant bending moment which may be given as:

All of them are attributed to either of the three groups:

1. Longitudinal- They are the stiffeners running longitudinally along the bottom of the ship (parallel to the baseline) from fore to aft. They stiffen the bottom-shell plating of the hull, hence preventing it from the external forces such as the wave loads and the internal forces such as loads of cargo or the other contents of the hull. Essentially they are girders of specified scantlings depending on the applicability of the vessel type.

1. Stringers-If we concentrate on the longitudinal stiffening at the side shell girders, stringers are the answer. They are like longitudinals, sideshell plating strengthening members on the hull. Even as the sideshell platings are prone to high amount of transverse wave stresses, they are also reserved to the maximum degree of rigidity

2. Deck Girders/ Longitudinals: Longitudinal stiffening underneath the main deck, i.e, in conjunction to the inner deck plating. They deck is prone to various types of loads, like passenger/crew, live loads, deck equipment, superstructure, green water etc. Thus deck girders running fore to aft serve the bulk of the purpose. However, they are not having high section modulus as lower bottom shell plating as the deck is considered relatively less affected by high stress as compared to the bottom.

· Transverse Stiffeners. They provide transverse stiffening across the breadth/beam of the ship. They are mutually orthogonal to the longitudinal stiffeners. Akin to their longitudinal counterparts, they too can be segregated into three forms based on their functionality.

1. Frames are the larger portions of these transverse stiffeners which run from the keel to the main deck uninterrupted. Frames occur at specified intervals throughout the length of the ship. The spacing between the frames is dependent upon the dimensions and the operation of the vessel along with its type. One crucial thing that must be kept in mind is that they are not to be confused with Stations nor Bulkheads. While the former is an imaginary hypothesis assumed by naval architects while shaping up their lines plan, the latter is a composite structural feature. But frames only align themselves with the side shell and the bottom shell plating without interfering with the inner aspects providing an integral contribution in stiffening plating transversely.

2. Floors assumed to be the continuation of the frames at the base. In general, they can be simply interpreted as the transverse stiffening of the bottom-shell plating. In the case of a single bottom ship, frames are sometimes connected directly to floor plates. The lower ends of tween deck frames are connected directly to the deck plating or are extended beyond deck-head and fixed at brackets.

However, in most of today's ships, the concept of double hull has been imbibed. Hopefully, all of you know what a double hull represent? For the novice, it is just enough to know that they are two-layered system of bottom plating, i.e an outer shell plate and another inner bottom shell plate with some clearance. Floors are generally sandwiched between the inner and outer shell plating to provide sturdiness to the bottom hull. Floors even have their type like solid floors and bottom floors, about which we refrain to comprehend at this juncture.

3. Deck Transverse They, like deck girders stiffen the deck-shell plating, but across the allowable beam. However, their strength and spacing depends on the type of the vessel and the 'superstructure loads'.

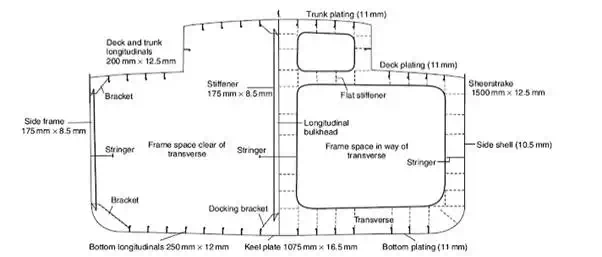

Fig. 12 A typical cross-section of a 5000 DWT coastal tanker showing all the essential stiffeners and resultant stiffened panels ( Courtesy: Ship construction by D.J. Eyres)

Reiterating the last point on Deck Transverses, it may be worthwhile to say

that the placement and the number of the longitudinal or stiffener framing

system is solely dependent on the type of vessel, capacity, service,

sea-states, cargo optimizing the owner's economical constraints with due

adherence to the Factors of Safety.

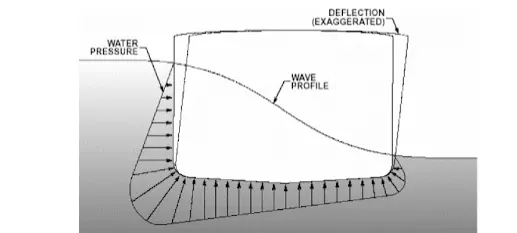

It may be suffice to know that in most of the smaller ships having Length-to-Breadth ratio not very high, the number of transverses are more than the number of longitudinals. The spacing inbetween the transverse stiffening members are also very less; they are crowded! This type of framing system known as Transverse Framing System is mostly deployed in the smaller vessels where longitudinal bending is not much of an issue. Transverse stiffeners provide resilience against transverse forces such as those induced by the side waves which can cause unwanted Racking and Torsional motions in the ship.

Fig. 13 Profile of the sideways wave forces and the transverse deflection/deformation inducing racking motions

On the contrary, in large/lengthy vessels such as general cargo ships or the majority of the passenger liners which are prone to longitudinal bending, buckling, flexure, there is more number of longitudinal stiffening induced in all along its length. The spacing between the longitudinals are reduced considerably. A ship of this type may be reckoned as a 'Longitudinally Stiffened Ship'.