Under the Skin: Part 1

Have you ever wondered what lies within the skin of the prodigious engineering marvels such like ships? You may be surprised to learn that ships or vessels like we humans and other living creatures have an intricate 'skeleton' underneath! Analogous to the complex network of bones and ligaments in living beings, they have a well-engineered arrangement of structural members in varying attributes.

Fig. 1 A high-definition picture of Queen Mary 2

You may still be in some doubt!

Large number of big and small components make up

the hull structure which is the primary phase of manufacturing of any vessel

and is the most tedious task. It is believed that the safety and sustainability

of the vessel during its service is a chunk dependent on the ingenuity of the

structural members and thereby the entire structure. Failure of any single

component leads to disastrous results. So, it is a challenging task to undergo

detailed selection, arrangement, analysis and testing methods to these

structures. With due respect to the traditional mechanical analysis methods of

materials along with empirical probabilistic methods, modern computational

testing methods accompanied by Finite Element Analysis and other precision

software have eased the cumber of the olden days providing a wider scope of

accuracy and precision.

SHIP'S HULL- AN OVERVIEW

A ship's hull is comprised of a criss-cross network of perpendicularly placed

plates or members which are fixated to each other at all possible degrees of

freedom. Some crucial members include extensive varieties of plates, struts,

columns, bars, beams, stanchions, angles, brackets, knees, elbows and so on.

Must be wondering the arrangement of all of these in a mere vessel? And that

too which floats and treads in water for such a long span of time!

The answer is quite simple. There is a holistic placement of all of them in

accordance to their capabilities which complies with their strength,

scantlings, locations, loads/stresses and their utilities. A ship, as we know

is a large structure aimed at overcoming all hindrances of distance, carriage

and cargo, sea-states, environmental vagaries, titanic loads accompanied by the

pressing issue of safety of life as well as property (cargo/machinery). Naval

architects, shipbuilders and designers owe a considerable amount of showmanship

regarding design, lines plan, materials, scantlings, strength and model

testings, intricate architecture of each component, related calculations and

final accuracy in materialization of the arduous job. An obvious question

arises at this juncture: What should be the apt choice for material selection

as far as the hull is concerned?

What is the material used?

Mild steel and wrought iron has been a sought-after choice of shipbuilders

around the globe after the departure of the yesteryear wooden/timber

vessels.However, in the recent times, wrought iron is losing its popularity

owing to its corrosive nature and being bulkier.Mild steel earns the reputation

of its abundance, ease in assemblage, lightweight along with required

strength, ductility and malleability. However it is prone to failure

under high stresses and hull shocks. It also has a degree of unreliability when

it comes to their service as girders, struts or internal supporting members,

with due respect to larger ships of today having massive tonnage. Furthermore

it is highly corrosive in nature and is also prone to other problems like

fouling. So, another breed of steel, High Tensile Steel/High Strength Steel

with increased yield points have stolen the limelight. They include grades of

steel like AH,DH,EH. Their yield point lies in the range of 315-350 MPa!

|

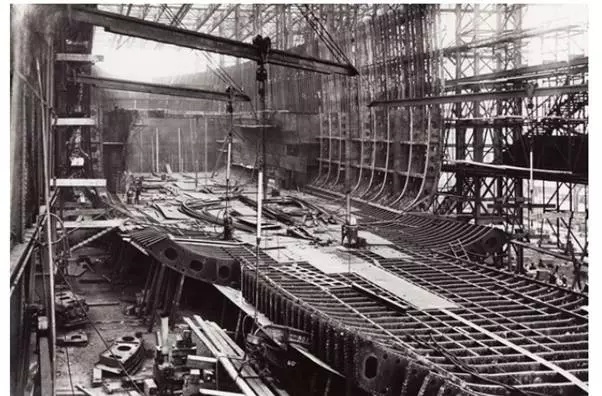

Fig.3: A very rare pic of The Titanic in construction. Wrought iron and mild steel were the chief materials used along with rivet joining |

But as it is said, everything has its pros and cons. High Steel Strength,

despite its high degree of toughness has poor response when it comes to the

problem of flexural bending. As longitudinal bending is inevitable in most of

the large ocean-going vessels, they often pose the risk of fracture due to

intensive bending moments at uncongenial sea states. The advent of composite

fabricated members in the modern shipbuilding has changed the scenario. Though

the SOLAS requirements and a majority of classification societies were dubious

about its utility in the superstructures or other deck areas, thanks to its

reduced fire resistance, the mid-1980s saw a gradual upraise of composite

fibers in the industry. As usual, supporting reasons existed!

· Lightweight. This helped in easily meeting the critical dead-weight barrier assigned to a ship. So this, up to a certain extent helped in greater "inclusion" of added mass on board which was a constraint if material was a bulky one like steel.

· It has a lower life cycle cost coupled with cheaper maintenance and durability.

· Due to its light weight, it amounted to lower fuel consumption.

· Higher stiffness and accorded to greater flexural bending moments by the virtue of its elasticity.

· Was tough and rigid with minimal scope of cracking. Offered greater resilience.

· Often use of composite material allowed higher superstructure and more accommodation space in passenger vessels designed for a given displacement.

· Its resistance to corrosion and fouling when present as a component in the hull structure was a boon.

FRP-sandwich panels/GRP-sandwich panels and PVC enforced steel plating found great predominance. Polymeric and non-polymeric materials found equal importance. However, composite had disadvantages as well like being highly flammable or being difficult to manufacture along with yielding at very high temperatures. Thus the decisive step is being taken as to optimize between steel and composite materials in suitable proportions for the best results.

part from these,

forged steel and cast steel are used in secondary structural components like

rudder posts, stern frame and stem according to the specifications of the

latest classification societies. Some classification rules even give higher

adherence to the existing Aluminium Alloys as the principal material for the

construction of deckhouses, superstructures, hatch openings, covers etc. over

composite materials.