Hatch Covers

It is generally accepted that leaking hatch covers are a principal cause of dry cargo wetting. Hatches leak for a variety of reasons, but mainly because of poor maintenance or failure to close them properly. Leaking or badly maintained hatch covers can lead to more serious consequences than wet cargo- flooding accelerated corrosion or even loss of the ship.

A watertight hatch cover is a cover designed to prevent the passage of water in either direction under a head of water for which the surrounding structure is designed. A weathertight cover is a cover designed to prevent the passage of water into the ship in any sea condition. Hatch covers are constructed to be weathertight, which means that, in any transient condition, water will not penetrate into the ship through the covers.

However, it is apparent that minor leakage into a cargo hold during a hatch cover test is often erroneously considered to be within a weathertight standard in practice, no leakage is the requirement. Your vessel will also carry oil and hence requirements are more stringent with respect to water tightness. Many mariners think hatches are robust, monolithic structures, thereby failing to appreciate the small tolerances on housing and gasket compression.

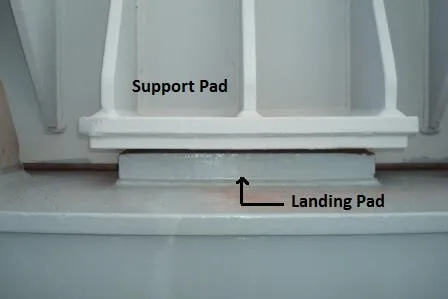

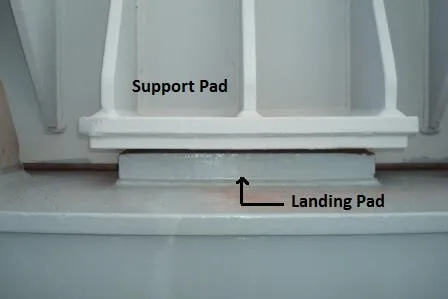

For example, a 4 mm wear on the steel-to-steel contact pads is sufficient to damage rubber sealing gaskets beyond repair; 5mm sag along the length of the gasket can cause a large gap between the compression bar and gasket.

It is better to think of the hatches as complex, finely –made structures, to be handled with care. It is our aim here to explain the key issues of hatch cover security and to achieve pro-active maintenance. It is crucial for safety at sea and protection of the environment to maintain hatch cover water tightness and strength. Please see the Appendix 2 and 3 for checklists on hatch maintenance and PMS.

Manufacturer | SEOHAE MARINE SYSTEMS |

Complies With | ICLL AND IACS URS21 [REV.4] |

Operational Parameters | CONSTRAINTS |

Max Heel | +/-3 DEGREES |

Max Trim | +/- 2 DEGREES [ abt 5.5 mtrs] |

Material | MILD STEEL 50% AND GRADE 36 HIGH TENSILE 50% |

Each hatch cover is operated by 1 hydraulic motor via rack and pinion driving system installed in the middle of the port side. All hatches roll open to the port side. The control stands are located at the aft transverse coamings between the hatches.

1F 11,400 X 17,100 /13280 mm

The other 9 hatches are of equal dimensions: 17,100 x 19000 mm.

Wheels are made of high tensile steel material and the forward hatch wheels are provided with rail flanges whilst the aft wheels do not have these rail flanges in order allow for a degree of free movement.

Weather Tightness: Solid Type Packing [NBR]

The rubber packing’s are installed in retaining channels made from hot rolled flat bar.

Is made of stainless steel with round top flat bar [ sus 304] on hatch coaming top.

Each Hatch Cover | ABOUT 73 MT |

Hardware | ABOUT 6 MT |

Additional Hardware | ABOUT 8 MT |

Total Approx Weight of Hatch Cover | ∞ 75MT |

The Cargo Cranes have a SWL of 30MT.

The purpose and function of a hatch cover and its coaming is to prevent ingress of water into a cargo hold after a large opening has been cut in the deck for cargo access. Hatch covers are a movable structure designed to a weathertight standard.

Typically hatch covers are lightweight steel grillages. Modern design methods using finite element technology enable more efficient material distribution which results in lighter (thinner) structures. Construction from high tensile steel results in even thinner plate being used. For this reason these lightweight structures must be ‘handled with care’. Prevention of corrosion is essential-safety margins are finite.

Hatch covers provide a primary structural and watertight barrier to prevent water ingress into cargo hold. Rigorous inspection, regular maintenance and prompt repair of damaged covers, securings and support are essential to maintain fitness for purpose and, in particular

· To maintain sufficient strength to resist green seas landing on hatches in extreme weather

· To maintain a barrier against ingress of water during normal seagoing weather conditions

Failure to maintain hatch covers correctly can lead to physical loss of a cover in extreme weather and hold flooding and possible foundering. Minor leakage can cause cargo damage and, if over a prolonged period , damage to the ship ‘s internal structure . Long-term structural decline can lead to structural collapse and total loss.

Fig 1: Support Pads and Landing Pads Making Steel to Steel Contact