Subsea Technology

The exploration and production of oil and gas reservoirs in a variety of water depth has become a challenge to the offshore industry.

Since these subsea developments are moving further offshore and into deeper waters, the technical challenges of such projects are continuously increasing.

For deep water developments a wide range of subsea layouts and production systems, greatly differing in complexity, are utilized.

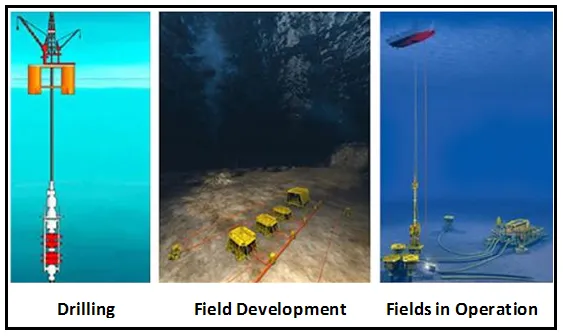

The latest subsea technologies have been proven and formed into an engineering system(the subsea production system) which is associated with the overall process and all the equipment involved in drilling, field development and field operation.

All segments of a subsea production system – From: Subsea engineering handbook – ELSEVIER 2010

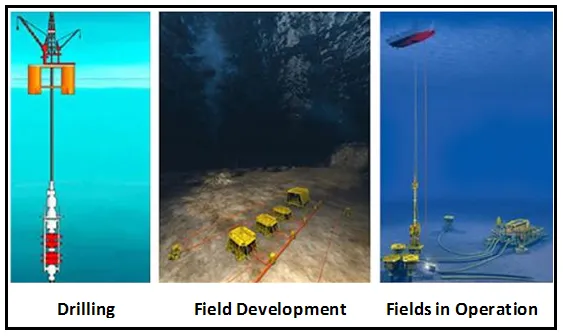

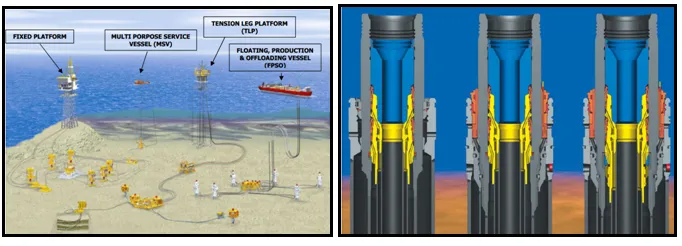

A subsea production system consists of a subsea completed well, subsea Christmas trees and wellhead systems, subsea tie-in to flow line system, jumpers, umbilical and riser system and subsea equipment to operate the well.

The single or clustered well can be connected through the flow line to a fixed platform, FPSO (Floating Production, Storage and Offloading) or onshore facilities.

Alternatively, an existing subsea production system can be connected to a newly operated production well by means of a subsea tie-back (popular in the development of new oil and gas reserves).

Due to the high pressures, potentially large temperature gradients and the harsh environment in deep-water, the subsea systems and equipment are subjected to complex and critical load cases.

Therefore in all offshore pipeline systems the transportation of fluids including the flow of oil, gas, water and mixtures should be analyzed to optimize performance and minimize the operational risks.

In subsea field development, the following issues should be considered:

SUBSEA PRODUCTION SYSTEM OPERATION

The typical operation of subsea production system can be summarized as follows:

Schematic of a typical subsea layout – From: Schlumberger Oilfield Review – 2006

SUBSEA ARCHITECTURE

The goal of subsea field development is to safely maximize economic gain using the most reliable, safe, and cost-effective solution available at the time.

Offshore architecture encompasses the hardware, systems, and equipment used to drill for, produce, and transport oil and natural gas from offshore locations.

This includes surface facilities, subsea equipment, and pipelines, as well as the tools and systems used to operate and maintain them.

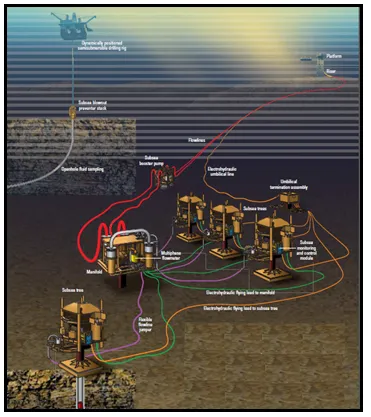

Subsea production systems architectures are generally arranged as shown in the figure below, but others are considered, based on several and different issue to be considered.

Subsea production system architecture – Typical subsea production system with wet tree (Source: Subsea engineering handbook – ELSEVIER 2010)

Some subsea production systems are used to extend existing platforms. example, the geometry and depth of a reservoir may be such that a section cannot be reached easily from the platform using conventional directional drilling techniques or horizontal wells.

Based on the location of the tree installation, a subsea system can be categorized as a dry tree production system or a wet tree production system and the water depth can also impact subsea field development.

For the shallower water depths, limitations on subsea development can result from the height of the subsea structures.

Even though wet well systems are still relatively expensive, their attraction in reducing overall capital expenditures has already been made clear.

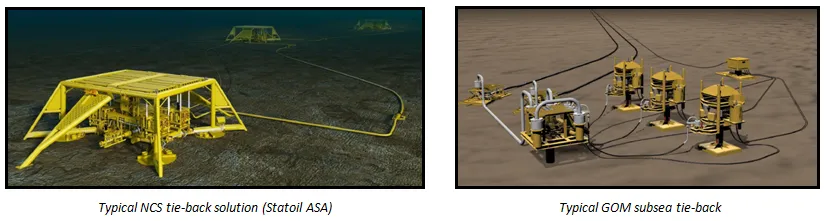

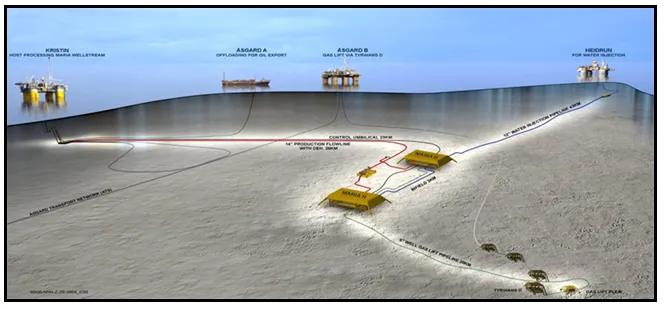

Subsea tie-backs are becoming popular in the development of new oil and gas reserves.

With tie backs architecture, existing infrastructure and platforms as well as pipelines are utilized with new subsea prospect being tied into old platforms.

These developments are often characterized by utilizing conventional and cost effective solutions and may therefore not be regarded as technology drivers, and due to known production regime, these developments may be developed efficiently and with little effort spend on tailored design

The Norwegian Continental Platform (NCS) is a region where subsea development have been adopted and represents an area of pioneering subsea technology application.

A typical NCS subsea field developments are based on the subsea equipment being located in template structures.

The template is the foundation that carries the weight and loads of the structure, and supports the wellhead and drilling activities, manifold and control system as well as the protection structure.

The protection structure covers the template, manifold and the trees to protect the equipment from third party damages as e.g. dropped objects, anchors or trawl equipment.

In other parts of the world where there is not a requirement that the equipment is overtrawlable the typical solution is to distribute the modules (trees, manifolds, etc.) with each having its own foundation on the seabed.

This will often be described as a clustered manifold solution, where a number of wells with XT’s are located as standalone units, producing through a jumper spool to a comingling manifold.

The control system is also a central unit (Subsea Distribution Unit – SDU) and distributes control signals, electrical and hydraulic power to manifold and Subsea Control Modules (SCM) as well as distribution of injection chemicals.

In ultra-deep water where the seabed tends to be softer, the SDU will be located onto the foundation that carries the manifold.

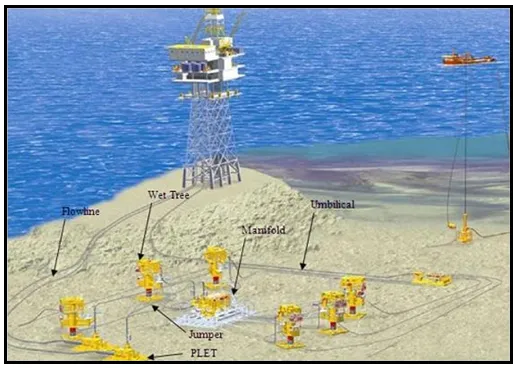

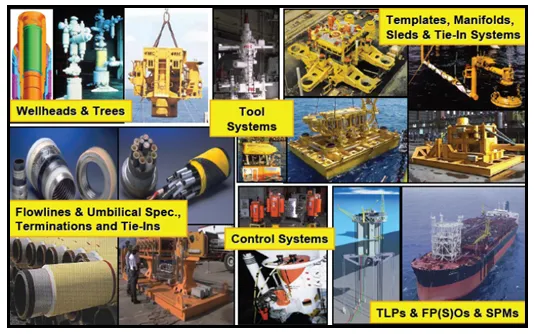

The subsea production system consists of the following components:

The figure below illustrates the major components of a subsea production system.

Subsea production system building blocks – From FMC Technologies

SUBSEA DRILLING AND WELL SYSTEMS

The subsea drilling and production business is dependent upon a variety of vessels to support exploration drilling, development, production and workover of wells in shallow and deepwater.

New and innovative operational methods are continuously being envisioned and developed to support these efforts.

The figure below displays four typical methods in which subsea well systems may be tied back in order to accommodate production.

For the a workover or completion, a semi submersible rig is typically used and for intervention, it is normal to use diving vessels or smaller service rigs.

Left :Offshore rigs and structure and subsea production systems

Right: Subsea Drilling System can be provided in different wellhead systems, for example FMC Technologies provides: Standard, Rigid Lock, and Large Bore as shown in the figure below, each of the system has different characteristics and finds diverse application.

SUBSEA WELLHEADS AND XMAS TREES

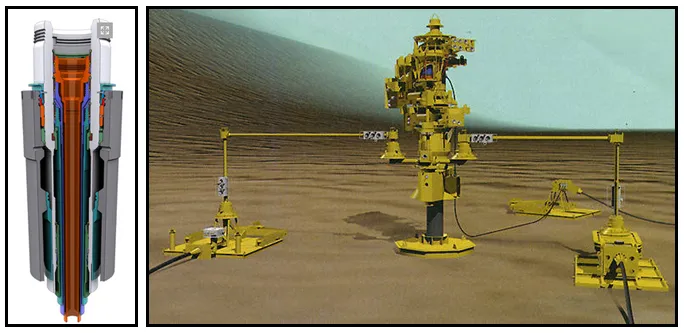

Subsea wellhead is a pressure-containing component at the surface of an oil well that provides the interface for drilling, completion, and testing of all Subsea operation phases.

It can be located on the offshore platform or onshore, in which case it is called a surface wellhead or it can also be settled down on the mudline, in which case it is called a subsea wellhead or mudline wellhead.

Subsea wells can be classified as either satellite wells or clustered wells.

Satellite wells are individual and share a minimum number of facilities with other wells.

The primary advantage of satellite wells is the flexibility of individual well location, installation, control, and service – each well is handled separately, so that its production and treatment can be optimized.

When several subsea wellheads are located on a central subsea structure, the system is referred to as a clustered system.

This arrangement provides the possibility of sharing common functions among several wells, such as manifold service or injection lines and common control equipment, which then require fewer flowlines and umbilicals (reducing costs).

Disadvantages of clustered systems are that drilling or workover operations on one well of the cluster may interrupt production from others and special simultaneous drilling and production procedures need to be implemented.

The subsea production tree is an arrangement of valves, pipes, fittings, and connections placed on top of a wellbore.

The valves can be operated by electrical or hydraulic signals or manually by a diver or ROV.

Left: Subsea Wellhead System – From: Onesubsea (Cameron & Schlumberger company)

Right: Schematic of the subsea tree which provides the interface between the wellheads and the infield flowlines – from Offshore Technology

SUBSEA MANIFOLDS

Production Manifold (Source: Onesubsea – Cameron & Schlumberger company)

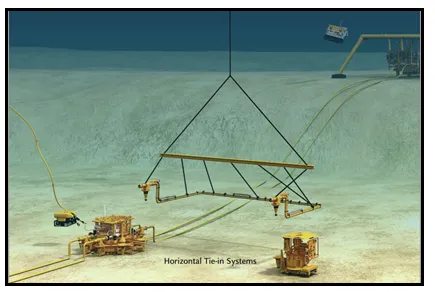

PIPELINE ENDS AND IN-LINE STRUCTURES

Pipeline end terminations (PLET)/ pipeline end manifold (PLEM), and in- line structure (ILS) are subsea structures designed to attach the pipeline end and then lowered to the seabed in the desired orientation.

The PLET/ PLEM is located at the end of a subsea pipeline, while the inline structure is located in the middle of the pipeline – a rigid or flexible jumper is utilized to tie-in the PLET/ILS to the other subsea structures e.g. tree, manifold, or other PLET/PLEM.

JUMPERS

In subsea oil/ gas production systems, a subsea jumper is a short pipe connector that is used to transport production fluid between two subsea components (for example, a tree and a manifold, a manifold and another manifold, or a manifold and an export sled).

It may also connect other subsea structures such as PLEM/PLETS and riser bases and ir can be used to inject water into a well.

The offset distance between the components (trees, flowlines, and manifolds) dictates the jumper length and characteristics.

Flexible jumper systems provide versatility, unlike rigid jumper systems, which limit space and handling capability.

Jumper are used to connect manifold systems to wells, sleds to wells and/or manifolds to sleds.

They can be chosen in rigid and flexible configurations in sizes from 4 to 18 inches diameter and lengths exceeding 150 feet (50 meters).

Tie-in connections are either vertical or horizontal, based on system selection. (Source: FMC Technologies)

UMBILICAL SYSTEMS

An umbilical is a bundled arrangement of tubing, piping, and/or electrical conductors in an armored sheath that is installed from the host facility to the subsea production system equipment.

An umbilical is used to transmit the control fluid and/or electrical current necessary to control the functions of the subsea production and safety equipment (tree, valves, manifold, etc.).

Dedicated tubes in an umbilical are used to monitor pressures and inject fluids (chemicals such as methanol) from the host facility to critical areas within the subsea production equipment.

Electrical conductors transmit power to operate subsea electronic devices.

Umbilical dimensions typically range up to 10 in. (25.4 cm) in diameter.

The umbilical will include multiple tubings normally ranging in size up to 2 in. (5.08 cm).

The length of an umbilical is defined by the spacing of the subsea components and the distance these components are located from the host facility.

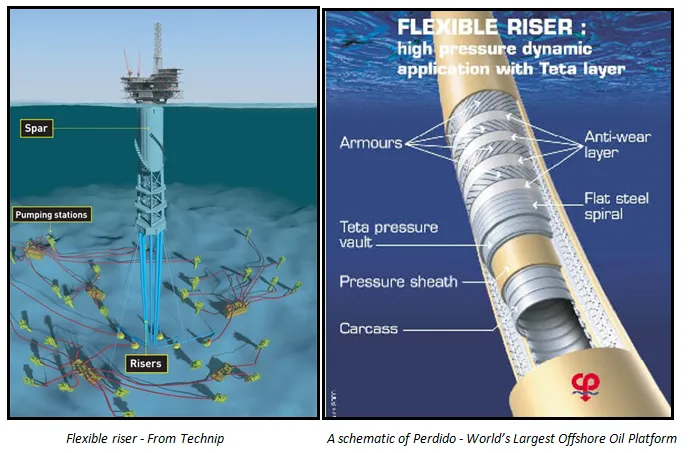

PRODUCTION RISERS

The production riser is the portion of the flowline that resides between the host facility and the seabed adjacent to a host facility.

Riser dimensions range from 3 to 12 in (76.2 to 304.8 mm). in diameter. Riser length is defined by the water depth and riser configuration, which can be vertical or a variety of wave forms.

Risers can be flexible or rigid and contained within the area of a fixed platform or floating facility, run in the water column.

SUBSEA FLOWLINES

Subsea flowlines are the subsea pipelines used to connect a subsea wellhead with a manifold or the surface facility.

The fiowlines may be made of flexible pipe or rigid pipe and they may transport petrochemicals, lift gas, injection water, and chemicals.

Flowlines may be single pipe, or multiple lines bundled inside a carrier pipe.

Both single and bundled lines may need to be insulated to avoid problems associated with the cooling of the produced fluid as it travels along the seabed.

The possible higher pressure condition results in the technical challenge of providing a higher material grade of pipe for high- pressure, high-temperature (HP/HT) flowline projects, which will cause sour service if the product includes H2S and saltwater.

Higher temperature operating condition will cause the challenges of corrosion, down-rated yield strength, and insulation coating.

Schematic of field development showing deployment of flowlines

From: Reinersten

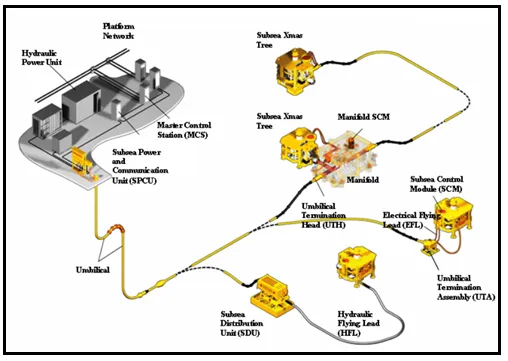

SUBSEA CONTROL SYSTEM AND INSTRUMENTATION

The subsea control system is a vital element in the subsea production system and it is vital that this performs reliably throughout the life of the field.

All subsea equipment located on the sea floor in both shallow and deep water need to be operated remotely.

Hydraulic and electrical functions need to controlled and monitored from the host facility control station. The control station (master control station or MCS) for the production control system can be located on a platform or on a floating facility such as an FPSO.

Selecting the correct type of control system is critical to ensuring safe, efficient and long term reliability of the system

Critical components of the system can be retrieved to surface for maintenance and replacement as required and the graphic below shows the major components of the subsea control system.

Subsea control system building block – From FMC Technologies

In a subsea system control system, typically hydraulic and electrical controls umbilicals will be connected between subsea components using relatively short lengths of umbilical.

For this requirement Hydraulic and Electric Jumper Umbilicals are used.

These can be located on subsea distribution modules located on the seabed positioned close to the subsea components e.g. Christmas tree or manifold.

An ROV would then connect the umbilicals.

Traditional developments have instruments for pressure and temperature monitoring of the produced fluids located on the tree.

The integrity of the production tubing is evaluated by monitoring the pressure between the production tubing and production casing through sensors located in the XT.

For the production path, instruments are normally located down-stream the production master valve.

The condition of the electrical supply through the umbilical is monitored from the topside Electrical Power Unit.

Today the subsea trees and manifolds are getting more instruments and are also often equipped with a multiphase meter which is getting more popular as they have become more accurate and reliable in operation.

The multiphase meters have been installed for better production optimization and to some extent for production allocation when different Operators are producing through same infrastructure to the processing unit.

With the introduction of subsea processing facilities, there will also be an increased need for electric power to operate electric motors and separator systems and their control systems.

Also Direct Electric Heating (DEH) of pipeline is becoming more popular which requires large amounts of power.

For signal transmission the industry is moving from communication using copper wire to fibre optic cables due to the massive increase in transmission capacity and speed.

SUBSEA INSTALLATION AND VESSELS

The development of subsea production systems requires specialized subsea equipment.

The deployment of such equipment requires specialized and expensive vessels, which need to be equipped with diving equipment for relatively shallow equipment work, and robotic equipment for deeper water depths.

Subsea installation refers to the installation of subsea equipment and structures in an offshore enviromnent for the subsea production system.

Installation in an offshore environment is a dangerous activity, and heavy lifting is avoided as much as possible.

This is achieved fully by subsea equipment and structures that are transmitted to the installation site by installation vessels.

Subsea installation can be divided into two parts:

Installation of subsea equipment such as trees and templates can be done by a conventional floating drilling rig, whereas subsea pipelines and subsea risers are installed by an installation barge using S-lay, J0-lay, or reel lay.

Special vessels can run the trees and rigless installation and subsea equipment to be installed is categorized based on weight, shapes (volume versus line type), dimensions, and water depth (deep versus shallow).

Snapshots of subsea installation and vessels

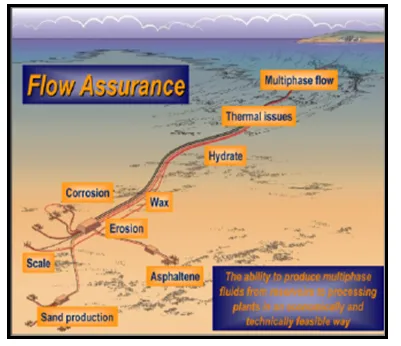

FLOW ASSURANCE

The buildup of wax, scale and hydrate deposits in wells, subsea flowlines, wellheads, risers and surface equipment is a special problem for subsea production where temperatures are quite low and the pressurized fluids are an un-processed wellstream.

Flow assurance is the new term referred to the study of the complex phenomena involved with steam of produced fluids in order to guarantee the maximum flow.

These fluids are comprised of a combination of gas, crude/condensate and water together with organic and inorganic solids: Hydrate, Scale, Wax / Paraffin, Sand, Asphaltenes

For an effective subsea production, it is necessary to identify the potential for and quantify the magnitude of all of these solid depositions in the production system.

Changing pressures, temperatures and production flow profiles over the field life also complicates the posed difficulties.

It is also necessary to control and predict potential problems during transient flow regime , which means that the system should be able to shutdown and restart in a controlled manner.

There are many considerations that go into designing an effective flow assurance program for a field and these include considering the requirements for all parts of the system for the entire production life.

Some of the considerations for an effective flow assurance program are listed below:

The petroleum industry are developing distributed sensors and other devices that can warn the operators of impending flow blockages.

Subsea Processing – From:STATOIL, 2011

In the context of Flow Assurance in subsea production system Flow Assurance System (FAS) – an advanced real time and simulation support system delivered by FMC Technologies with SPT Group and Prediktor as sub-suppliers – include online monitoring of potential flow assurance issues.

Thermal insulation and protective coating can be applied to components subjected to deepwater immersion.

Subsea Thermal Insulation with materials of superior thermal properties helps delay the onset of hydrate formation and wax deposition or DEH (Direct electric heating) is also an alternative mature and growing technology which can keep fluid temperatures above the hydrate formation temperature and above the wax appearance temperature.