CONTACT RATIO

The sum is the total contact ratio, εɣ.

The overlap contact ratio component exists only in gear pairs that have helical or spiral tooth forms.

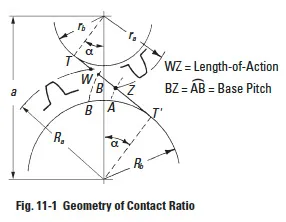

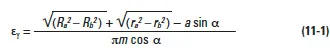

11.1 Radial Contact Ratio Of Spur And Helical Gears, εα

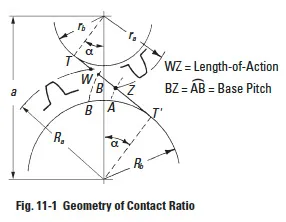

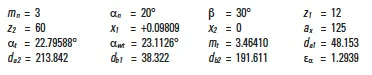

The equations for radial (or plane of rotation) contact ratio for spur and helical gears are given in Table 11-1, with reference to Figure 11-2.

When the contact ratio is inadequate, there are three means to increase it. These are somewhat obvious from examination of Equation (11-1).

An example of helical gear:

Note that in Table 11-1 only the radial or circular (plane of rotation) contact ratio is considered. This is true of both the spur and helical gear equations. However, for helical gears this is only one component of two. For the helical gear's total contact ratio, εɣ, the overlap (axial) contact ratio, εβ, must be added. See Paragraph 11.4.

11.2 Contact Ratio Of Bevel Gears, εα

The contact ratio of a bevel gear pair can be derived from consideration of the equivalent spur gears, when viewed from the back cone. See Figure 8-8.

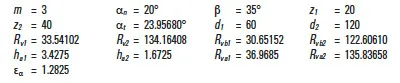

With this approach, the mesh can be treated as spur gears. Table 11-2 presents equations calculating the contact ratio.

An example of spiral bevel gear (see Table 11-2):

11.3 Contact Ratio For Nonparallel And Nonintersecting Axes Pairs, ε

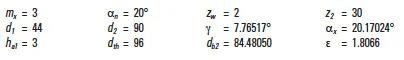

This group pertains to screw gearing and worm gearing. The equations are approximations by considering the worm and worm gear mesh in the plane perpendicular to worm gear axis and likening it to spur gear and rack mesh. Table 11-3 presents these equations.

Example of worm mesh:

11.4 Axial (Overlap) Contact Ratio, εβ

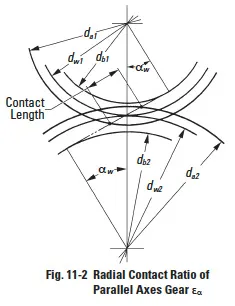

Helical gears and spiral bevel gears have an overlap of tooth action in the axial direction. This overlap adds to the contact ratio. This is in contrast to spur gears which have no tooth action in the axial direction.

Thus, for the same tooth proportions in the plane of rotation, helical and spiral bevel gears offer a significant increase in contact ratio. The magnitude of axial contact ratio is a direct function of the gear width, as illustrated in Figure 11-3. Equations for calculating axial contact ratio are presented in Table 11-4.

It is obvious that contact ratio can be increased by either increasing the gear width or increasing the helix angle.