SLIDING CONTACT BEARINGS – CLASSIFICATION

Sliding contact bearings are classified in three ways.

1. Based on type of load carried

2. Based on type of lubrication

3. Based on lubrication mechanism

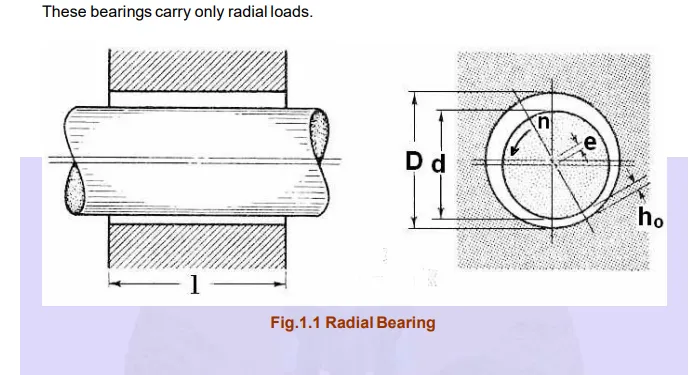

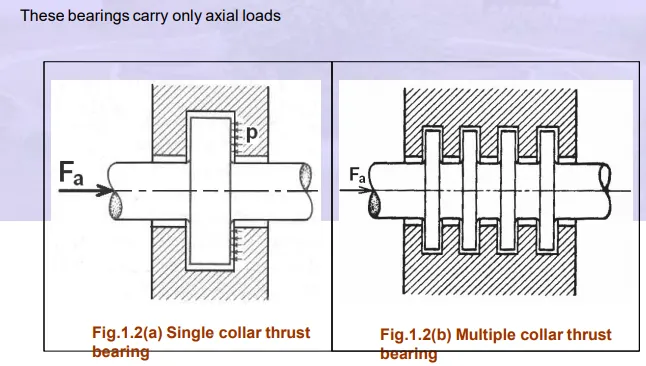

Bearing classification based on type of load carried

(a) Radial bearings

(b) Thrust or axial bearings

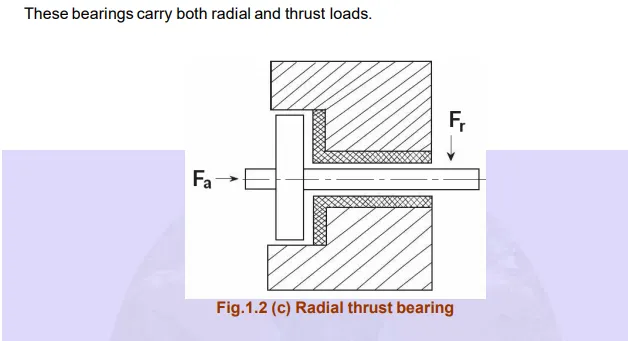

(c) Radial thrust bearings

Bearing classification based on type of lubrication

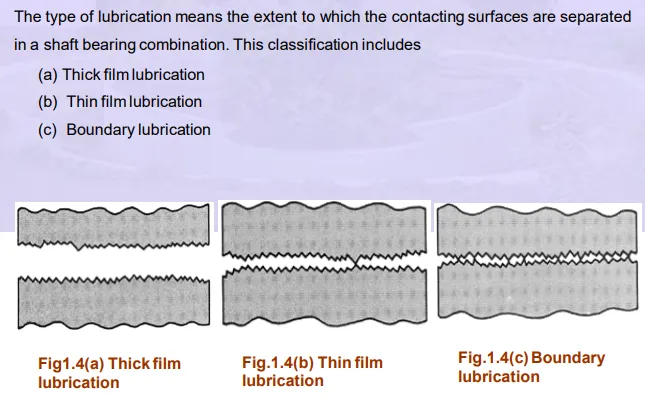

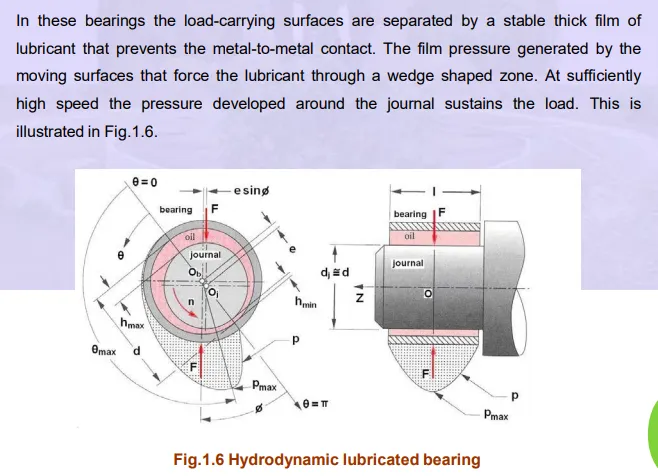

(a) Thick film lubrication – As in Fig.1.4 (a) the surfaces are separated by thick film of lubricant and there will not be any metal-to-metal contact. The film thickness is anywhere from 8 to 20 μm. Typical values of coefficient of friction are 0.002 to 0.010. Hydrodynamic lubrication is coming under this category. Wear is the minimum in this case

(b) Thin film lubrication – Here even though the surfaces are separated by thin film of lubricant, at some high spots Metal-to-metal contact does exist , Fig.1.4 (b).Because of this intermittent contacts, it also known as mixed film lubrication. Surface wear is mild. The coefficient of friction commonly ranges from 0.004 to 0.10.

(c).Boundary lubrication – Here the surface contact is continuous and extensive as Shown in Fig.1.4(c). The lubricant is continuously smeared over the surfaces and provides a continuously renewed adsorbed surface film which reduces the friction and wear. The typical coefficient of friction is 0.05 to 0.20

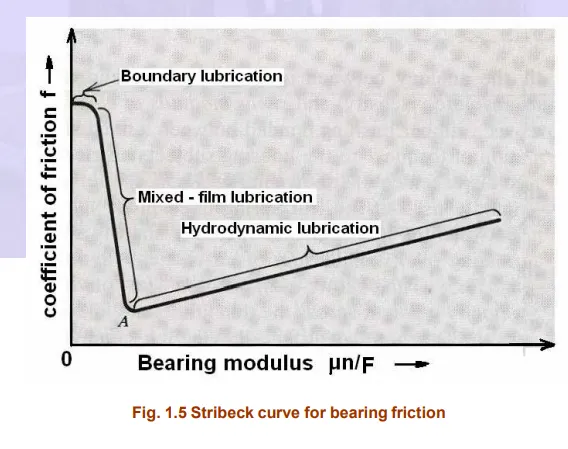

Bearing classification based on lubrication mechanism

The operating regimes of different lubrication mechanisms are depicted by Stribeck in Fig.1.5 by plotting coefficient of friction verses the non-dimensional factor known as bearing modulus.

(a) Hydrodynamic lubricated bearings

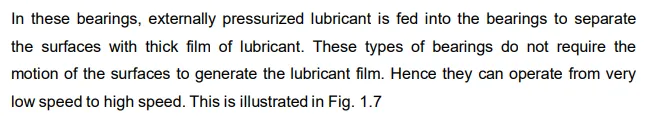

(b) Hydrostatic lubricated bearings

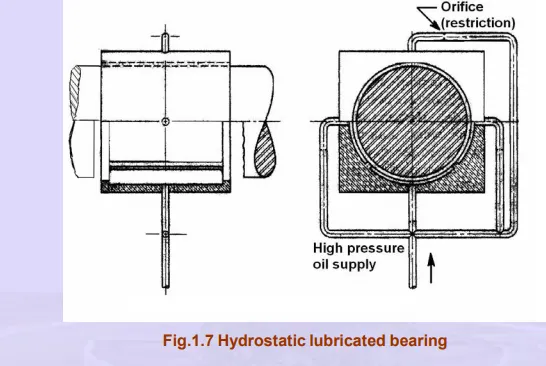

(c) Elastohydrodynamic lubricated bearings

Rolling contact bearings come under this category. The oil film thickness is very small. The contact pressures are going to be very high. Hence to prevent the metal-to-metal contact, surface finishes are to be of high quality. Such a type of lubrication can be seen in gears, rolling contact bearings, cams etc.

(d) Boundary lubricated bearings

When the speed of the bearing is inadequate, less quantity of lubricant is delivered to the bearing, an increase in the bearing load, or an increase in the lubricant temperature resulting in drop in viscosity – any one of these may prevent the formation of thick film lubrication and establish continuous metal-to-metal contact extensively. Often bearings operating in such situations are called boundary lubricated bearings.

(e) Solid film lubricated bearings

For extreme temperature operations ordinary mineral oils are not satisfactory. Solid film lubricants such as graphite, molybdenum disulfide or their combinations which withstand high operating temperature are used. These types of bearings are common in furnace applications, or trunnion bearings of liquid metal handling systems, hot drawing mills etc.