marine hydraulics

The application areas are many. Listed below are some of the uses of marine hydraulic systems:

At Sleipner Motor, we primarily use hydraulic systems for our stabilizing vector fins and our thruster systems, but we also manufacture hydraulic steering systems for a range of high-end yachts and work boats.

If correctly dimensioned, installed and commissioned, a hydraulic system requires little maintenance, and troubleshooting is pretty easy for personnel with a reasonable knowledge of general hydraulics. The two most important factors for trouble-free operation are:

In terms of cleanliness, this cannot be stressed enough on marine hydraulics. The most crucial factor for a problem-free operation is keeping the system clean and the oil-free from impurities.

Marine hydraulic can be divided into three types of systems:

The most common system is the open hydraulic system. The open system is characterized by having a pressureless tank to which the oil is returned more or less directly. Contrary to a closed system in which the oil return is directly on the pump's suction side. All hydraulic systems built by Sleipner Motor for our Side-Power systems are open hydraulic systems. Semi-closed and closed hydraulic systems will not be discussed further in this series of hydraulic talks.

A typical floor-mounted 90 liter tank from Side-Power.

Typical marine hydraulic components

The most common components in an open hydraulic system on boats are:

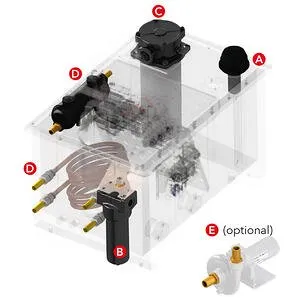

It is essential for the lifetime and reliability of a hydraulic system that the oil stays clean and within correct temperatures to avoid excessive wear and damage to any of the components in the system. The Side-Power hydraulic system is designed to achieve this by having:

A Air filter and strainer in filler cap.

B High-pressure filter with service indicator.

C Return filter with service gauge.

D Dual internal oil cooler or tank mounted in-line return cooler and drain cooler. Setup and mounting will vary depending on selected tank unit and system setup.

E DC or hydraulic driven water pump for the oil coolers (optional).

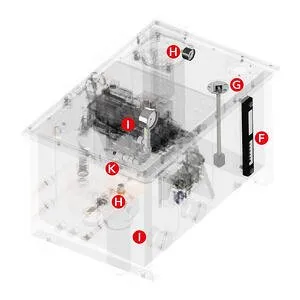

For safety and ease of service there are several sources of information and warnings on the tank.

F Oil level and temperature gauge.

G Electric alarm outputs for oil level and temperature to Side-Power control panels with a visual and audible alarm.

H Both filters have gauge/indicator for filter element condition.

I Pressure gauge on valve shows system pressure.

K Pressure sensor for control panel monitoring.

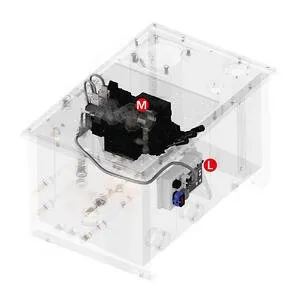

L PHC-3 Controller (Proportional Hydraulic Controller).

M Valve system.