Mechanising the infusion process. Direct-Infusion

· The controlled delivery of resin directly into the fibre under a vacuum bag without any intermediate containers.

· Control of resin mixing ratio, flow rate, and mould inlet pressure.

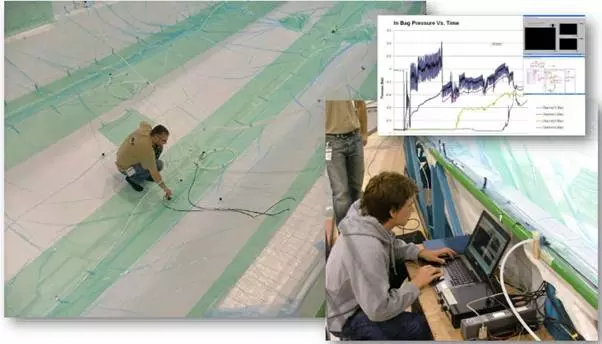

· Use of sensors (IMPS) to accurately measure and control In-Mould Pressure

What is Direct-Infusion

· Reduced H&S risks (no open container of resin or manual contact necessary)

· Reduced risk of bulk exotherm

· Materials can be degassed prior to infusion

· Accurate pressure control

· Reduced wastage

· Improved laminate quality

· Control and monitoring for QA

· Repeatability

Advantages of Direct-Infusion

Developing the Direct-Infusion process

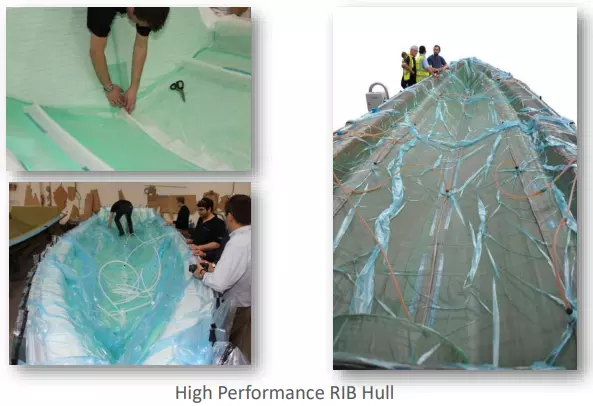

Examples of Direct-Infusion