Control valves -2

Classification of control valve according to number/ways of switching position

Three position four way (3/4) valves

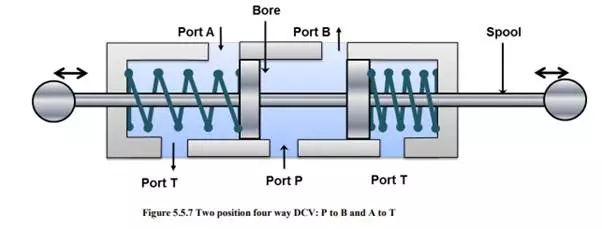

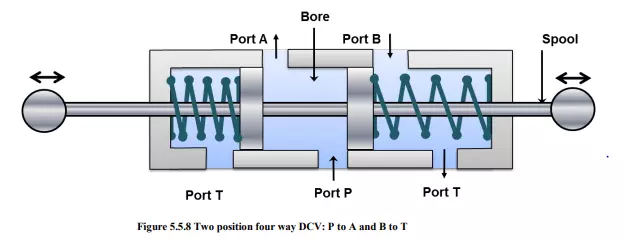

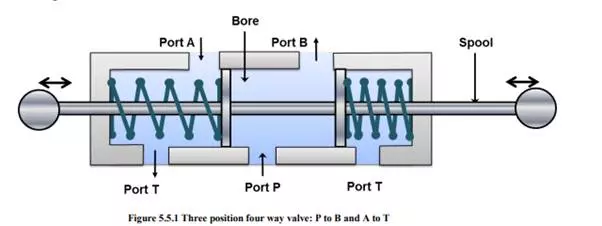

Three position four way (3/4) valves are used in double-acting cylinders to perform advance, hold and return operation to the piston. Figures 5.5.1 and 5.5.2 show three position four way valves. These types of valves have three switching positions. They have a variety of possible flow path configurations but have identical flow path configuration. When the centered path is actuated, port A and B are connected with both the ports P and T respectively. In this case, valve is not active because all the ports are open to each other. The fluid flows to the tank at atmospheric pressure. In this position work cannot be done by any part of the system. This configuration helps to prevent heat buildup.

When left end (port B) is actuated, the port P is connected with ports B and T is connected with port A as shown in Figure 5.5.1. Similarly, when the right end is actuated the port P is connected to A and working port B is connected to port T as shown in Figure 5.5.2. The three position valves are used when the actuator is needed to stop or hold at some intermediate position. It can also be used when the multiple circuits or functions are accomplished from one hydraulic power source.

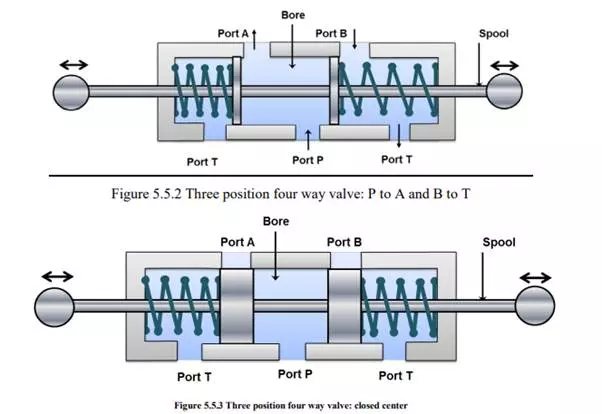

Figure 5.5.3 shows a three position four way valve in the closed center position. The working of the valve is similar to open center DCV. In closed center DCV all user ports (port A and port B) are closed. Therefore, these ports are hydraulically locked and the actuator cannot be moved by the external load. The pumped fluid flows through the relief valve. The pump works under the high pressure condition which not only wastes the pump power but also causes wear of the pump parts. The fluid temperature also rises due to heat generation by the pump energy transformation. The increase in fluid temperature may lead to the oxidation and viscosity drop of the fluid. The oxidation and viscosity drop reduces the pump life and leakage in the system.

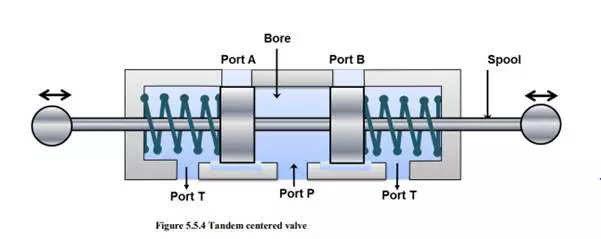

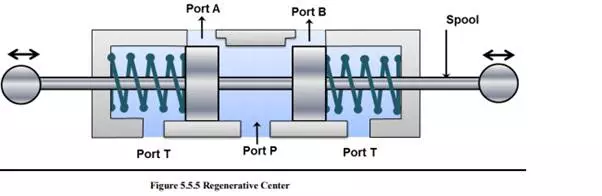

Figure 5.5.4 shows a tandem center three position four way direction control valve. In this configuration, the working ports A and B are blocked and the pump port P is connected to the tank port T. Tandem center results in the locked actuator. However, pump to tank flow takes place at the atmospheric temperature. This kind of configuration can be used when the load is needed to hold. Disadvantages of high pressure pumping in case of closed center (shown in Figure 5.5.3) can be removed by using this configuration. The regenerative center is another important type of common center configuration used in hydraulic circuits. Regenerative means the flow is generated from the system itself. Regenerative center is used when the actuator movement in one direction requires two different speeds. For example, the half-length of the stroke requires fast movement during no-load condition and remaining half-length requires slow motion during load conditions. The regenerative center saves the pump power.

Figure 5.5.5 shows the regenerative configuration for the three position four way (3/4) DCV in its mid position. This configuration increases the piston speed. In the mid position pump Port P is connected to A and B, and tank port T is blocked.

Figure 5.5.6 shows the floating center 3/4 DCV in its mid position. In this configuration, the pump port is blocked and both the working ports A and B are connected to the tank port T. Therefore, the working ports A and B can be moved freely which is reason they are called as floating center. The pumped fluid passes through the relief valve. Therefore, pump works in the high pressure condition. This configuration is used only in some special cases.

Two position four way (2/4) valves

The two position four way valves have only two switching positions and do not have any mid position. Therefore, they are also known as impulse valves. The typical connections of 2/4 valves is shown in Figures 5.5.7 and 5.5.8. These valves can be used to operate double acting cylinders. These are also used to reciprocate or hold an actuator. The operation is faster because the distance between ports of these valves is smaller. Hence, these valves are used on machines where fast reciprocation cycles are needed such as punching and stamping etc.