Spool valve

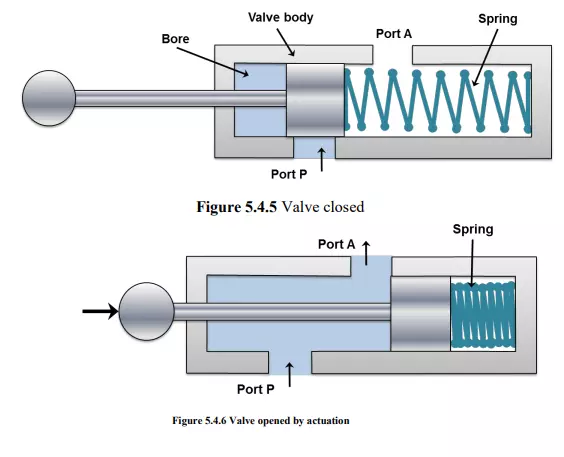

The spool valves derive their name from their appearance. It consists of a shaft sliding in a bore which has large groove around the circumference. This type of construction makes it look like a spool. The spool is sealed along the clearance between moving spool and housing (valve body). The quality of seal or the amount of leakage depends on the amount of clearance, viscosity of fluid and the level of the pressure. The grooves guide the fluid flow by interconnecting or blocking the holes (ports). The spool valves are categorized according to the number of operating positions and the way hydraulic lines interconnections. One of the simplest two way spool valve is shown in Figure 5.4.5. The standard terms are referred as Port ‘P’ is pressure port, Port ‘T’ is tank port and Port ‘A’ and Port ‘B’ are the actuator (or working) ports. The actuators can move in forward or backward direction depending on the connectivity of the pressure and tank port with the actuators port.

Number of ports

Two way valves

Two way valves have only two ports as shown in Figure 5.4.5 and Figure 5.4.6. These valves are also known as on-off valves because they allow the fluid flow only in direction. Normally, the valve is closed. These valves are available as normally open and normally closed function. These are the simplest type of spool valves. When actuating force is not applied to the right, the port P is not connected with port A as shown in figure 5.4.5. Therefore, the actuation does not take place. Similarly, Figure 5.4.6 shows the twoway spool valve in the open condition. Here, the pressure port P is connected with the actuator port A.

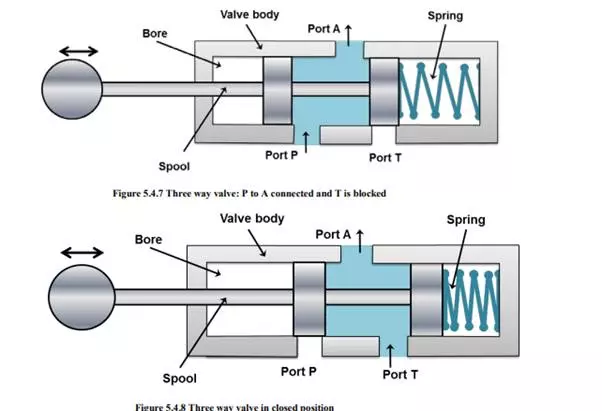

Three way valves

When a valve has one pressure port, one tank port and one actuating port as shown in Figures 5.4.7 and 5.4.8, it is known as three way valve. In this valve, the pressure port pressurizes one port and exhausts another one. As shown in figures, only one actuator port is opened at a time. In some cases a neutral position is also available when both the ports are blocked. Generally, these valves are used to operate single acting cylinders.

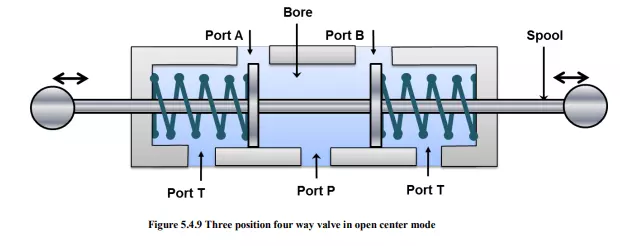

Four way valves

Figure 5.4.9 shows a four-way valve. It is generally used to operate the cylinders and fluid motors in both the directions. The four ways are: pump port P, tank port T, and two working ports A and B connected to the actuator. The primary function of a four way valve is to pressurize and exhaust two working ports A and B alternatively.