Earth Fault on Ships

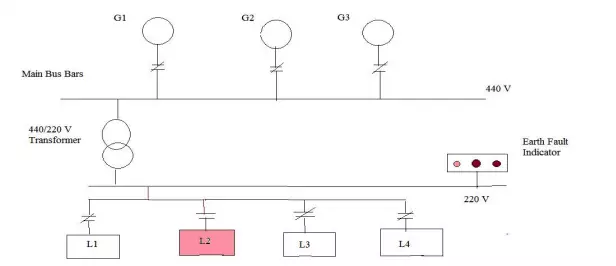

Earth fault is considered very critical on board a ship. Some ships, which operate at 440V do not have any trip devices attached for a single earth fault. However, when the operating voltage exceeds 3000V, it is mandatory to have a protection system that isolates when ship machinery suffers an earth fault.

The seriousness of the action to be taken on an Earth Fault depends on the part of the electrical system it affects. Conventional ships which operate on 3 Phase, 440V, have earth fault indicators installed on all three phases.

Any earth fault on a 440V system is considered to be a serious trouble and immediate action is required to identify the faulty circuit. Earth fault on 220V or any low voltage lighting circuit can be considered as important but need not require immediate attention. However, attention should be paid at the next earliest opportunity.

Finding Earth Fault on 440V circuit

Whenever there is an earth fault alarm, immediately inform the electrical officer (if he is on board). First action is to check the trueness of the alarm. Usually there will be a test button which when pressed, resets the alarm and rechecks the condition of the earth fault.

If the ship is having IAS (Integrated Automation System), check on the computer in the list of events, after which the alarm has activated. If IAS facility is not available, there is only one option left i.e. isolating each and every machinery system in the 440 V circuit.

When this is done, check for which machinery the earth fault indication returns back to normal.

Isolation of all machinery, which operates on 440V is not always possible. Certain critical equipment like steering gear and lubricating oil pumps cannot be isolated when the ship is underway. However changeover can be done from running machinery to the standby one and the earth fault can be found.

Finding Earth Fault on 220V Circuit

Finding an earth fault on a 220V circuit is comparatively difficult than a 440V circuit. The main reason being the lighting circuits found all-round the vessel. However, any earth fault alarm with respect to a 220V circuit is usually treated as important but not an emergency.

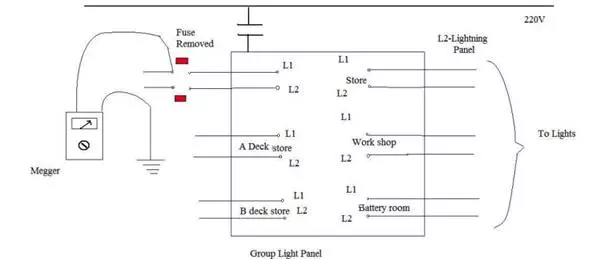

When a 220V earth fault alarm sounds, as said earlier, pressing the test button checks the trueness of the alarm and then investigation can be started on each and every 220V circuit.

Example: Earth Fault Alarm Sounds on a 220V Panel

· Check the trueness of the alarm

· Isolate the complete group start panel for a lighting division one by one

· Check the Earth Fault indicator for status (still faulty or normal)

· If faulty, then put on the breaker which is put off earlier and isolate other group start panel for lighting circuit

· Once the group start panel is identified, then individual lighting switches are turned off one by one and checked for the alarm condition

· When any switch is turned off and the condition becomes normal, the lighting circuit is marked and then inspection is done on the particular light for abnormalities.

Ingress of moisture is most common reason for an earth fault.

Alternate Idea: Instead of turning off breakers one by one for the lighting circuit, turn off the lighting circuit of a particular doubted area. This method helps when there are two or more earth faults in 220V lighting circuit.

Turning off all the breakers of a particular area and then switching on the breaker one by one will eliminate multiple earth faults.

When turning off lighting switches one by one, it is difficult to identify multiple earth faults.

Once the particular faulty circuit is spotted, then further break them into individual parts and check them for earth faults. For this, usually a megger against earth is used.

By removing the fuse of the two-phase lines, each line can be tested and the fault pinned down.