Methods of Starting IC Engines

Starting devices are commonly employed with compression ignition engines and especially with the engines fitted with turbulence combustion chambers. Petrol engines as well as gas engines and small units of low compression C.I. engines may be started by hand or by electric starters. Generally the instruction book supplied by the manufacturers must be carefully studied for the starting procedure.

With larger units in the low compression class of C.I. engines the following methods are used for starting:

(1) Blow lamp

(2) Electric heater in the combustion chamber

(3) Compressed air

(4) Special cartridge.

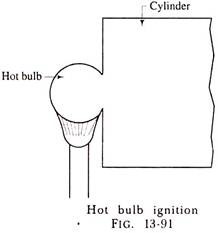

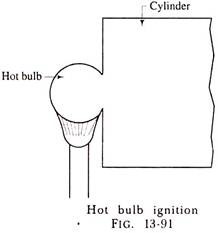

Fig. 13-91 shows the blow lamp method of starting. The blow lamp is applied to the hot bulb or uncooled part of the cylinder until the spot is hot enough to ignite the oil vapour. The engine is then barred over and when injection occurs the oil ignites and the engine commences to run.

The electric heater acts exactly as the blow lamp, but the heat is supplied by electrical means. A compression relief valve is also used with smaller units to facilitate the work of starting. The medium and high compression engines are invariably started by compressed air.

The air is used for a few cycles to store up energy in the flywheel and the oil is sprayed in. In multi-cylinder engines the cylinders are brought into action one or two at a time. For road vehicles with Diesel engines all cylinders but one are cut off and the engine is started by electric starter or hand. When the engine has run for a .few seconds the other cylinders are brought into action.

The compressed air may be provided by means of:

(i) Hand driven compressors for small units

(ii) Compressors driven by the engine itself

(iii) Separately driven compressors.