Gearing for screw engines and its abandonment.

In order to attain the same speed of ship the screw propeller had to be driven

at a much greater speed than the paddle-wheel, and as it was not possible in the

then condition of mechanical engineering to drive the pistons at a sufficiently

high speed to enable the engine shaft to be connected directly to the propeller

shafting, the earlier engines used for working screw propellers were geared, so

that the screw shaft was caused to revolve at a much higher rate of speed than

the engine shaft.

A large spur wheel, keyed on the crank-shaft of the engine, worked into a

pinion on the screw propeller shafting, so that the speed of the engine shaft

could be multiplied on the screw shaft as might be necessary. Before

long, however, such improvements in workmanship and mechanical details

were effected, that the speeds both of piston and of revolution could be

sufficiently increased to allow direct engines to be fitted.

In these the gearing is left out, and the crank-shaft connected direct to the

screw shafting. In many marine engines at the present day, even of the largest

size, the mean piston speeds are as high as from 800 to 950 ft. per minute at

the maximum power, while in the fast-running engines supplied for torpedo boats

and destroyers it rises as high as 1,200 ft. per minute, and in extreme cases

to 1,400 ft. It is probable that in the future of marine engineering the speeds

may be increased even beyond this, in order to attain increased economy.

Horizontal engines.

The paddle-wheel engines were either vertical or inclined; but when the screw

propeller was introduced, and it became possible to place the whole of the

propelling apparatus below the water-line, the engine was placed horizontally,

and from that time, for about thirty years, the engines of warships

were almost always of the horizontal type. One of the great obstacles that

had then to be overcome in connecting the crank-shaft of the horizontal engine

direct to the screw shafting was the close proximity in which the cylinder

was necessarily placed to the centre-line of the ship, owing to the

limitation of the beam of the ship, which made it difficult to get a

connecting-rod of suitable length to work between the cylinder and the

crank.

Trunk engines.

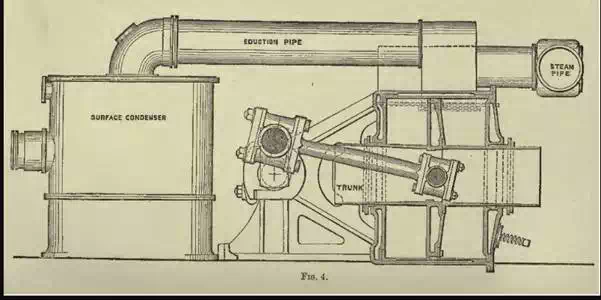

Mr. John Penn solved this difficulty by his invention of the trunk engine. In

this engine a large hollow trunk, cast on or bolted to the

piston, and working through a steam-tight stuffing-box on the end of the

cylinder, was substituted for the piston-rod, and the

connecting-rod was attached directly to a journal or gudgeon in the centre of

the piston itself, as shown in Fig. 4.

Though the use of a large trunk of this description does not at first sight appear desirable, yet the engines of this type have generally worked in a satisfactory manner, and they were amongst the most smooth-working and efficient marine engines employed. With the introduction of high-pressure steam, however, they became obsolete, owing to the difficulty of keeping the trunks in a steam-tight condition.