Abandonment of side-lever engines.

Attempts were soon made to reduce the space required by the machinery, and the

side-levers were abandoned and direct-acting engines fitted for rotating the paddle-wheels.

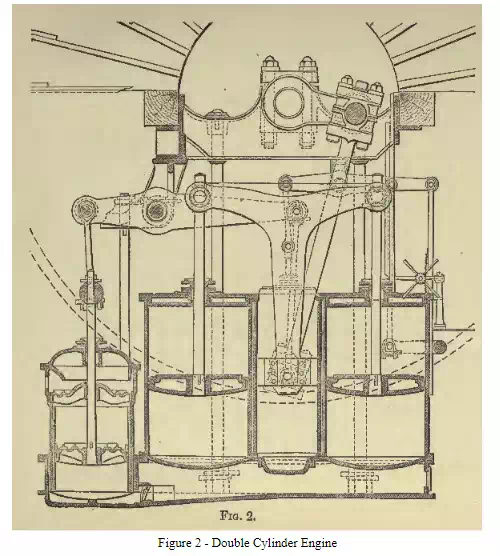

Several arrangements of this kind were fitted, the two best known being the

double-cylinder engine by Messrs. Maudslay and the oscillating engine adopted

by Messrs. Penn. Fig. 2 shows the double-cylinder engine, which

consisted of two equal cylinders side by side, the piston-rods from the

two cylinders being connected to a single cross-head. In order to get

sufficient length of connecting-rod, the cross-head was of peculiar form and

passed down between the cylinders, having a journal at its lower end, on which

one end of the connecting-rod worked, the other end being attached to the

crankpin.

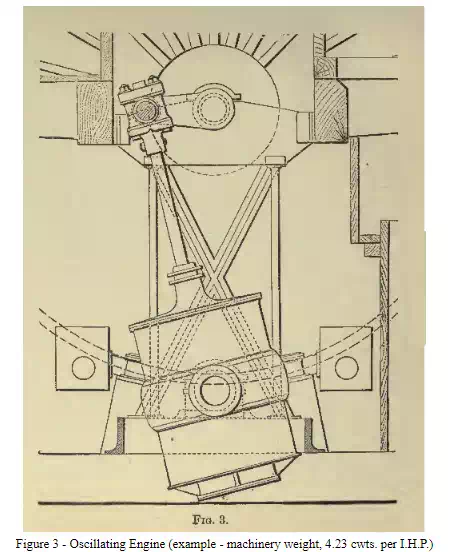

Fig. 3 shows

the general arrangement of the oscillating engine, which is the

simplest and most compact type for driving paddle-wheels. This type of engine,

although first fitted for marine purposes by Messrs. Maudslay, Sons, &

Field, who in 1828 fitted a pair of oscillating engines into the steamship

'Endeavour,' and subsequently in several other ships, was adopted and perfected

by the late eminent engineer, Mr. John Penn, with whose name it is now

generally associated.

In these engines the connecting-rod is altogether dispensed with, the

upper end of the piston-rod being fitted with brasses to work directly on the

crankpin, and the cylinder itself is carried on trunnion bearings, to allow the

necessary oscillation to suit the motion of the crank. The trunnions are

hollow, and the steam is admitted to and exhausted from the cylinders through

them. In this type of engine, space and weight have been economised as

far as is posslble for paddle-wheel engines, and the majority of engines now

made for paddle-wheel vessels are on this plan.

The 'Magicienne' was one of the best specimens of the steam war-vessels of that

period. She was fitted with oscillating engines by Messrs. Penn in 1850. The

pressure of steam in the boilers was 14 lbs. per square inch, number of

revolutions per minute at full power 20 1/2, giving a mean piston speed of 287

ft. per minute, with a maximum I.H.P. of 1,300. The total weight of the

machinery was 275 tons, or 4.23 cwts. per I.H.P.