Modern Steam

The steam turbine continues to be a major factor in electric power generation throughout the world. Even nuclear power plants use the heat from a controlled nuclear chain reaction to produce needed steam. In the United States, more than 88 percent of all electricity is produced by steam turbines

As mentioned earlier, there are basically three stages of matter: Solid, liquid and gas. Each stage is held together by a different level of molecular force. With water, gaseous steam takes up space due to its molecules being furthest apart. However, when enough pressure is applied to steam, an amazing thing happens. The molecules are forced together to the point that the water becomes more like a liquid again, while retaining the properties of a gas. It is at this point that it becomes a supercritical fluid.

Many of today's power plants use supercritical steam, with pressure and temperature at the critical point. This means supercritical steam power plants operate at much higher temperatures and pressures than plants using subcritical steam. Water is actually heated to such a high pressure that boiling does not even occur.

The resulting high-pressure fluid of supercritical steam provides excellent energy efficiency. With the aid of high pressure, supercritical steam turbines can be driven to much higher speeds for the same amount of heat energy as traditional steam power. They also release less CO2 exhaust into the atmosphere. Additionally, new high-pressure boilers built with rocket technology are being developed to further control the levels of CO2 emitted. Some boilers will even cool the steam back into a liquid and channel it into the ground to capture emissions.

The future is bright for steam on other fronts as well. In the search for alternative automobile fuel systems, some scientists continue to pursue the 15th century dream of a car driven on steam power.

How do Steamboats Work?

A HISTORIC FORM OF TRAVEL

Great steam-powered paddlewheel riverboats have plied the rivers of the United States for 200 years. The grand American Queen, constructed in 1995 in Morgan City, Louisiana, carries on the tradition of the elegant 19th century steamboat travel.

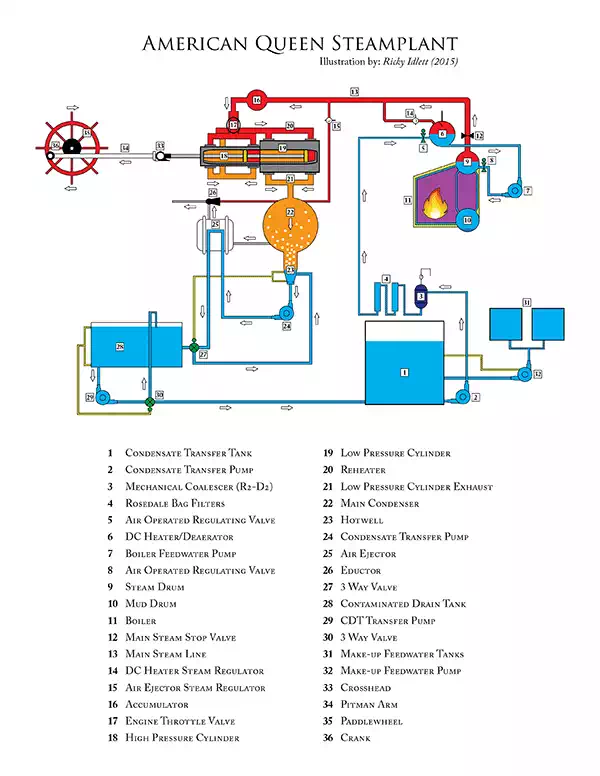

What makes the American Queen different from most of the riverboats in existence today is that a true steam engine is used to drive the paddlewheel. This steam engine is basically the same as the engines of the past century. How does a steamboat work then, you may ask? The American Queen’s stern wheel is driven by a four-cylinder, horizontally-inclined, tandem-piston, steeple compounded, double-acting reciprocating steam engine. While this may sound complicated, it is pretty easy to understand.

COMPREHENDING THE TERMINOLOGY

To truly understand how a steamboat works, we need to review some basic terminology. There are four steam cylinders. One high and one low pressure cylinder are on each side of the paddlewheel. “Steeple Compound” means the steam is expanded twice within the engine with the two cylinders attached directly to each other. Therefore, the high pressure cylinders receive “live” steam from the boiler to move their pistons down the cylinder bore. After the steam is expanded in the high-pressure cylinder, it is exhausted into the low-pressure cylinder. The steam then expands again, allowing more work to be performed than in a single expansion engine. Tandem piston means that the high and low-pressure pistons are mounted on the same piston rod, in the way that two people ride a tandem bicycle.

A double-acting

engine is powered by the steam on both the out and return strokes, which

effectively doubles the number of cylinders, resulting in eight expansions in

each revolution of the paddlewheel. The engine is lying down rather then

standing on end and is therefore said to be horizontal. Horizontally installed

engines distribute the machinery weight over a larger area of the hull, thus

reducing the vessel’s draft in shallow water.

THE AMERICAN QUEEN’S ENGINES

The engine on the American Queen came from the U.S. Army Corps of Engineer’s dredge Kennedy. It was assembled in 1932 by Nor Nordberg Manufacturing Company of Milwaukee, Wisconsin. The Kennedy was decommissioned after the 1984 World’s Fair in New Orleans, sold to Bolivar County, Mississippi, and its dredging equipment was reused by the county. Ultimately, the dredge went out of service and was moored in Rosedale, Mississippi.

In June of 1992, a survey of the machinery was conducted and the decision was made to utilize the Kennedy’s engines on the American Queen. Upon acceptance of a bid for the engines, salvage work commenced. Restoration took place in Newcastle, Indiana, by Newcastle Engineering, Inc. The engines were then transported by truck to Morgan City, Louisiana, and installation commenced in September of 1994 by the American Queen’s onboard Engineering Department.

Twenty-eight thousand pounds per hour of “live” steam at 300 pounds per square inch is generated by the combustion of #2 marine fuel in a single Babcock & Wilcox. The American Queen’s engineering plant is operated 24 hours a day, every day of the year, by a complement of officers and crew licensed by the United States Coast Guard. They maintain a tradition begun almost 200 years ago by pioneering rivermen who threw logs into copper boilers to move steamboats upriver in spite of crude equipment and tough working conditions. With the knowledge and efforts of these dedicated steamboaters, overnight paddlewheel passenger service continues on America’s rivers and continues to be a unique part of America’s heritage.

The engine room onboard the American Queen is open to guests. The next time you are onboard, stop in to see how a steamboat engine works for yourself.