Welding Methods And Weld Defects

Welding is one of the most widely used hot-work processes used in the shipbuilding industry. The development in welding technology has enabled the industry to produce perfectly watertight and oil-tight joints. Welded joints as compared to riveted joints are much easier to produce and they reduce the cycle time of the project. Welded joints have also resulted in reduced steel weight and require less to negligible maintenance compared to rivet joints. The major contribution of welding technology to the shipbuilding industry is the possibility of producing smooth hull surfaces, therefore reducing the bare hull resistance and power requirements considerably.

Welded joints as compared to riveted joints are much easier to produce and they reduce the cycle time of the project. Welded joints have also resulted in reduced steel weight and require less to negligible maintenance compared to rivet joints. The major contribution of welding technology to the shipbuilding industry is the possibility of producing smooth hull surfaces, therefore reducing the bare hull resistance and power requirements considerably.

The three main welding techniques that are used in a shipyard are as follows:

· Arc Welding

· Gas Welding

· Resistance Welding

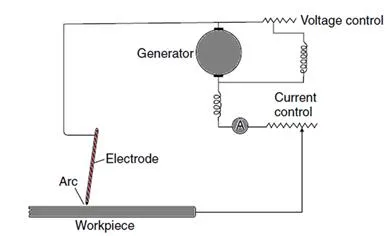

The fundamental principle of arc welding is to connect a metal electrode to an electrical power supply, forming a closed circuit if the plate is touched with the electrode. When the electrode is raised from the plate by a few millimetres, the electric current jumps the gap and an electrical arc is created at high temperature. This results in melting the parent metal and the metal in the electrode, allowing both the metals to fuse.

Figure 1: Circuit diagram of arc welding process.

Arc shielding is an important aspect of all arc welding processes. In order to prevent oxidation the fused metal, the arc is shielded from the ambient air, and contact with oxygen and water vapour are cut off. The two mostly used shielding techniques used by shipyards are as follows:

· Slag Shielded Arc Welding

· Inert Gas Shielded Arc Welding

Slag is the residue left over after the parent metals and the electrode metal has fused. It forms a layer over the arc and the welded joint, protecting it from oxidation. The presence of slag stabilises the arc, providing a better weld quality. There are three main Slag Shielded Arc Welding processes used in shipyards:

• Shielded Metal Arc Welding: The filler metal of most electrodes used in the shipbuilding industry is mild steel. Mild steel drawn in form of rods are coated with a mixture of mineral oxides, fluorides, silicates, hydrocarbons, and a liquefied binder which binds them together to form a solid envelope around the fuller metal. This coating forms the slag, stabilises the arc and prevents oxidation of the joint. Shielded metal arc welding is used in the fabrication of panels, grillages, tank units, etc. They are used in manual arc welding processes, and can help achieve welding at different positions, namely:

· Down hand welding.

· Overhead welding.

· Vertical welding.

Positional flexibility with this welding process makes it the only welding process used to weld the underside of overhead deck plates.

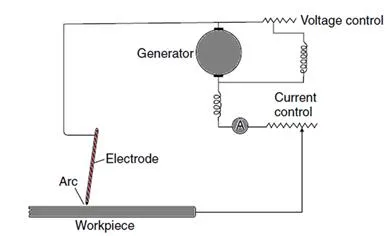

• Submerged Arc Welding: In this welding process, the arc is sparked and maintained under a blanket of granulated flux which is laid on the weld joint before the arc strikes the joint. Follow the figure to understand it further.

Figure 2: Submerged Arc Welding.

A hopper containing granulated flux runs along the length of the weld joint. It deposits a blanket of flux on the joint. The hopper is followed by a trolley which holds the filler metal electrode. The electrode is continuously fed by rollers driven by a drive motor, and the feed rate of the electrode is set to such a value so that the electrode tip is always submerged within the flux. The arc is hence generated within the layer of flux, allowing complete insulation from the environment.

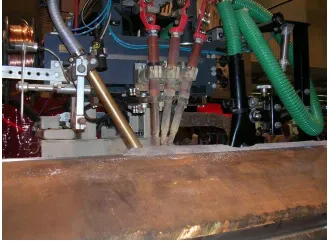

Figure 3: Submerged arc welding with a hopper leading three arc nozzles. (Source: wikipedia )

The speed of movement of the trolley, the feed rate of electrode and amount of flux on the joint are very important parameters that are pre-decided depending on the thickness of the plates, the material of the parent metal, and quality of weld joint to be achieved.

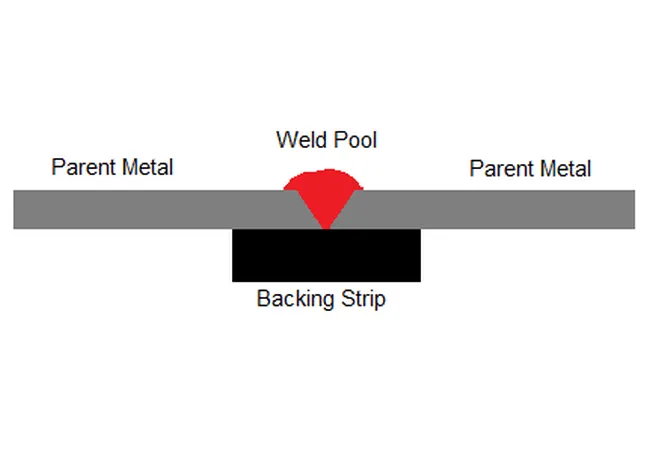

Submerged arc welding is the most commonly used downhand welding method in the shipbuilding industry, owing to its arc stability and quality of joint. Since most of the joints are welded on one side, a backing strip made of ceramic material is placed under the joint, to prevent the flow of weld bead from the other side.

Figure 4: Use of backing strips.

• Stud Welding: This welding process is used when a stud or bolt is to be welded to a parent metal. The stud is fixed at the muzzle of the stud welding gun. When the gun is fired, the stud is struck onto the metal. The high velocity of the stud along with the completed electric circuit generates the arc which fuses both the metals. Once the stud is driven into the metal, the electrical supply is automatically cut off. Granular flux is contained at the end of each stud to provide insulation from air.

This process is used for fastening insulation panels to bulkheads, wooden flooring onto deck plates.

Gas shielded arc welding processes use a blanket of a gas, instead of flux, to provide insulation to the arc against the ambient environment. They are used extensively in shipyards to welding the comparatively lighter structures.

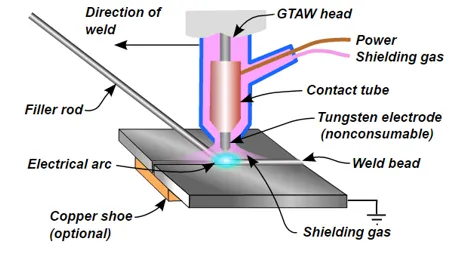

• Tungsten Inert Gas Welding (TIG): In this welding process, the arc is created between a non-consumable tungsten electrode and the parent metal plates. The tungsten electrode is surrounded by a nozzle that maintains a continuous flow of an inert gas around the arc. This inert gas shields the arc from oxygen, hence stabilising it, and preventing oxidation of the weld pool. A filler rod is introduced into the arc, which helps in the fusion of the two metals. The inert gas used in this process is usually Argon. TIG welding is preferred for plates of thickness usually less than 6 to 8 mm.

Figure 5: Tungsten Inert Gas Welding

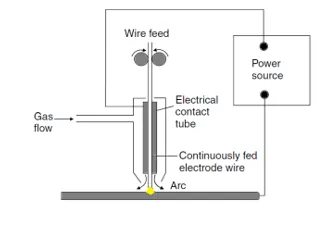

• Metal Inert Gas Welding (MIG): Metal inert gas welding is, in a way, an advancement on tungsten inert gas welding, where the electrode is a consumable metal wire.

Figure 6: Metal Inert Gas Welding.

The welding torch consists of an electrical contact tube which connects the electrode wire to the power supply. The electrode wire is continuously fed into the nozzle by a pair of driver rollers. It passes through the electrical contact tube. The flow of an inert gas is maintained into the welding torch through a separate line leading into the torch. It creates a blanket of inert gas around the stabilized arc.

Carbon dioxide is the most widely used inert gas for this purpose. MIG welding has been widely used in welding of aluminium deckhouses and spherical membrane tanks in liquefied gas carriers.

We will also discuss some of the other welding processes used in the shipbuilding industry for specialised purposes:

• Plasma Welding: This is similar to the process of TIG welding, except for the fact that the tungsten electrode is separated from contact with the plasma. Plasma is shot into the weld joint, which increases the temperature and provides shielding effect. This welding process is used for thinner metal sheets, most usually, in sheet-metal workshops in a shipyard.

• Laser Welding: Laser welding processes are used in advanced shipyards, and since this requires minimum heat input, the welding distortions (we will discuss this in detail soon) produced are minimised. The source of the laser in this process is either carbon dioxide or Nd:YAG (neodymium yttrium aluminium garnet) crystals.

• Thermit Welding: Thermit welding is more of a typical fusion process which is used to hold together large steel sections or forgings, for examples heavy sections of the stern frame of a ship. The heating in this welding process is achieved from a mixture of aluminium and iron oxide.

• Friction Stir Welding: This is a widely used process in shipyards, the source of heat being friction created between the rotating pin and the parent metal plates. The advantage of this welding process is its feasibility in the vertical direction, which makes it possible to friction weld but joints of side shells between blocks of a ship.