Marine Control Valves

For the shipbuilding industry, Korean Shipbuilders has a great role to satisfy industrial demand through many types of ships such as LNGC, Container Carriers, Bulk Carrier, Crude Oil Tank, Chemical Tank, Etc. During those big period of abundant shipbuilding, Korean valve manufacturers also has support the development of shipbuilding industry through their enough experience and technology. For ship’s operation lots kind of control valves are essential and those valves are mainly pressure control valve, temperature control valve, flow control valve, etc at many important place with fluids of oil, water, steam and air in ships.

Pneumatic Control Valve

Application

Engine Room

– Purifier F.O / L.O Heater Temperature Control

– Main Engine F.O Supply Line Pressure Control

– Steam Pressure Reducing Line

– EGE Excess Steam Dumping Line

– I.G.S Steam Dumping Control

Equipment

– Tank Cleaning System Level Control

Specification

Type | Globe |

Actuator | Pneumatic Diaphragm |

Applicable Fluids | Steam, Water, Oil |

Applicable Press./Temp. | 20 kgf/㎠ / 220℃ |

Material (Body / Trim) | Ductile Cast Iron, Bronze, Cast Steel / Stainless Steel |

Flow characteristics | Equal Percentage, Linear, Quick opening |

Rangeability | 30 : 1 / 50 : 1 |

Size | 15 ~ 350 mm |

Operating Air pressure | 0.2 ~ 1.0 kgf/㎠ / 0.4~2.0 kgf/㎠ |

Accessories (Option) | ● Controller(E/P, P/P) ● Positioner(E/P, P/P) |

♦ JIS, DIN, ANSI design is applicable.

♦ Class Application : BV, LR, ABS, DNV/GL, LINA, KR, NK, CCS

Electric Motorized Control Valve

Application

Engine Room

– Purifier F.O / L.O Heater Temperature Control

– Main Engine F.O Supply Line Pressure Control

– Steam Pressure Reducing Line

– EGE Excess Steam Dumping Line

– I.G.S Steam Dumping Control

Equipment

– Tank Cleaning System Level Control

Specification

Type | Globe |

Actuator | Electric Motor |

Applicable Fluids | Steam, Water, Oil |

Applicable Press./Temp. | 16 kgf/㎠ / 220℃ |

Material (Body / Trim) | Ductile Cast Iron, Bronze, Cast Steel / Stainless Steel |

Flow characteristics | Equal Percentage, Linear, Quick opening |

Rangeability | 30 : 1 / 50 : 1 |

Size | 15 ~ 300 mm |

Power Supply / Input Signal | 220V, 110V / 4~20mA |

Accessories (Option) | ● Controller(P.I.D) ● Control Box ● Sensor(Pressure, Temp.) |

♦ JIS, DIN, ANSI design is applicable.

♦ Class Application : BV, LR, ABS, DNV/GL, LINA, KR, NK, CCS

3Way Pneumatic Control Valve

Application

Engine Room

– Main Engine Jacket Fresh Water Temperature Control

– Aux. Fresh Water Cooler Temperature Control

– Main L..O Temperature Control

Equipment

– Vacuum Condenser Level Control

Specification

Type | Globe |

Actuator | Pneumatic Diaphragm |

Applicable Fluids | Water, Oil |

Applicable Press./Temp. | 16 kgf/㎠ / 180℃ |

Differential Pressure | Ductile Cast Iron, Bronze, Cast Steel / Stainless Steel |

Operation | Dividing / Mixing |

Material (Body / Trim) | Ductile Cast Iron, Bronze, Cast Steel / Stainless Steel |

Flow characteristics | Linear, On/Off |

Rangeability | 30 : 1 |

Size | 15 ~ 200 mm |

Operating Air pressure | 0.2 ~ 1.0 kgf/㎠ / 0.4~2.0 kgf/㎠ |

Accessories (Option) | ● Controller(E/P, P/P) ● Positioner(E/P, P/P) ● Sensor(Pressure, Temp.) ● Air set |

♦ JIS, DIN, ANSI design is applicable.

♦ Class Application : BV, LR, ABS, DNV/GL, LINA, KR, NK, CCS

3Way Electric Motorized Control Valve

Application

Engine Room

– Main Engine Jacket Fresh Water Temperature Control

– Aux. Fresh Water Cooler Temperature Control

– Main L..O Temperature Control

Equipment

– Vacuum Condenser Level Control

Specification

Type | Globe |

Actuator | Electric Motor |

Applicable Fluids | Water, Oil |

Applicable Press./Temp. | 10 kgf/㎠ / 180℃ |

Differential Pressure | 2.0 kgf/㎠ |

Operation | Dividing / Mixing |

Material (Body / Trim) | Ductile Cast Iron, Bronze, Cast Steel / Stainless Steel |

Flow characteristics | Linear, On/Off |

Rangeability | 30 : 1 |

Size | 25 ~ 200 mm |

Power Supply / Input Signal | 220V, 110V / 4~20mA |

Accessories (Option) | ● Controller(P.I.D) ● Control Box ● Sensor(Pressure, Temp.) |

♦ JIS, DIN, ANSI design is applicable.

♦ Class Application : BV, LR, ABS, DNV/GL, LINA, KR, NK, CCS

3Way Pneumatic Rotary Valve

Application

Engine Room

– Main Engine Jacket Fresh Water Temperature(High Temp) Control

– Aux. Fresh Water Cooler Temperature Control

– Main L..O Temperature Control

Specification

Type | Rotary, Rotar Disc Type |

Actuator | Pneumatic Cylinder |

Applicable Fluids | Water, Oil |

Applicable Press./Temp. | 10 kgf/㎠ / 80℃ |

Operation | Dividing / Mixing |

Material (Body / Trim) | Ductile Cast Iron, Bronze, Cast Steel / SS400, Bronze, 316SS |

Flow characteristics | Linear, On/Off |

Rangeability | 30 : 1 |

Size | 80 ~ 600 mm |

Operating Air pressure | 1.4 kgf/㎠ |

Accessories (Option) | ● Controller(E/P, P/P) ● Positioner(E/P, P/P) ● Sensor(Temp.) ● Air set |

♦ JIS, DIN, ANSI design is applicable.

♦ Class Application : BV, LR, ABS, DNV/GL, LINA, KR, NK, CCS

3Way Electric Motorized Rotary Valve

Application

Engine Room

– Main Engine Jacket Fresh Water Temperature Control

– Aux. Fresh Water Cooler Temperature Control

– Main L..O Temperature Control

Specification

Type | Rotary, Rotar Disc Type |

Actuator | Electric Motor |

Applicable Fluids | Water, Oil |

Applicable Press./Temp. | 10 kgf/㎠ / 80℃ |

Operation | Dividing / Mixing |

Material (Body / Trim) | Ductile Cast Iron, Bronze, Cast Steel / SS400, Bronze, 316SS |

Flow characteristics | Linear, On/Off |

Rangeability | 30 : 1 |

Size | 80 ~ 600 mm |

Power Supply / Input Signal | 220V, 110V / 4~20mA |

Accessories (Option) | ● E&P Controller(Pi, P.I.D) ● Sensor(Temp.) |

♦ JIS, DIN, ANSI design is applicable.

♦ Class Application : BV, LR, ABS, DNV/GL, LINA, KR, NK, CCS

E&P Controller

Application

E&P Controller is supplied with control valves to control pressure or temperature locally

Specification

Supply Voltage | 110/220VAC,50/60Hz,24V DC |

Operating Voltage Range | 90~110% of Rated Voltage |

Power Consumption | 10W(MAX.) 6W(Steady State) |

Input Signal | 4~20mA,PT100ohm,K,(1~5V) |

Output Signal | DC4~20mA / AIR1.4~2.4K |

Control Action | DIRECT or REVERSE |

Accuracy | +/-0.3% of Full Span |

Control Functions | PID Control Functions, Auto-Tuning |

Alarm Output | Relay Contact Output(A) , Error LED Lamp |

Local Set Point Adjustment | UP/DOWN Push Button |

Display | LED,FND Display |

Adjustable Parameters | SV,PV,PID,Unit |

Self-Diagnostic | Watch-Dog Circuit |

Communication(optional) | RS232 or RS485(Option) |

P&P Controller

Application

Pressure Control Valve _ Positioner Control Type

Temperature Control Valve – Positioner Control Type

Specification

Type | Pressure Controller | Temperature Controller |

Supply pressure | 1.4 ~ 4.0 kgf/㎠ | |

Output pressure | 0.2 ~ 1.0 kgf/㎠ / 0.4 ~ 2.0 kgf/㎠ | |

Measuring pressure | 0~10 / 0~16 / 0~20 kgf/㎠ |

|

Temperature range |

| 0~100 / 0~150 ℃ |

Protection grade | IP54 | |

Control action | P.I / P.I.D | |

Connection(sensor pocket) |

| PT 1/2″ , PT 3/4″ |

Level Controller

Application

Equipment

– Tank Cleaning Heater System

– Vacuum Condenser

– Level Control System

Specification

Nominal Pressure | Max 25 bar up to 250℃ |

Operating Temperature | 1 to 250℃ |

Ambient Temperature | 1 to 80℃ |

Density of Liquid | Min 0.7kg/c㎥ |

Control Connections | G 1/8″ (BSPP) inside thread |

Supply Pressure | 1.4 bar |

Output Signal | 0.2 to 1.0 bar |

Linearity | ±5%(of full scale output) |

Protection grade | IP54 |

Control Action | P (proportional) |

Positioner

Application

Control Valve

– Temperature Control Valve

– Pressure Control Valve

– Level Control Valve

Specification

Type | E&P | E&P | P&P | P&P |

Operation type | Linear | Rotary | Linear | Linear/Rotary, HART |

Input signal | 4~20mA | 0.2~1.0 / 0.4~2.0kgf/㎠ | ||

Supply pressure | 1.4~7.0 kgf/㎠ | |||

Air connection | PT 1/4” | |||

Protection grade | IP66 | |||

Ambient temp. | -30℃~85℃ | |||

Material | Aluminum diecasting | |||

Air Filter Regulator

Application

Equipment

– with Control Valves

Specification

Applicable Fluid | Air |

Max supply pressure | 15 kg/c㎥ |

Max ouput pressure | 4.2 kg/c㎥ / 8.4 kg/c㎥ |

Air connection | PT 1/4″ |

Material | Aluminum diecasting |

Temperature Sensor (RTD sensor)

Application

Temperature Control Valve

Specification

Temperature | -60~200℃ |

Protection grade | IP54 |

Cable gland | 15a / 20a |

Connection | PT 1/2″ |

Thermowell | |

Max.working temperature | 220℃ |

Max.working pressure | 70 kgf/㎠ |

Connection | PT 1/2″ / PT 3/4″ |

P/I (pressure to current) transducer

Application

Equipment

– Pressure Control Valve

Specification

Type | Pressure to current | Current to pressure |

Supply voltage / Pressure | DC24V(12~32V) | 7kgf/㎠ |

Input signal | 0.2~1.0kgf/㎠ | 4~20mA |

Output signal | 4~20mA | 0.2~1.0kgf/㎠ |

Operating temperature range | -40℃ ~ 125℃ | -30℃ ~ 65℃ |

Cable gland | PG11.5(cable:Φ6.8~11.5) | 22GA. 3 wire leads |

Connection | PT 1/4” | 1/4-20 NPT |

Protection grade | IP65 | |

Temperature Regulating Valve

Application

Engine Room

– Main Engine Purifier F.O / L.O Heater Temperature Control

– Generate Engine Purifier L.O Heater Temperature Control

– H.F.O Purifier Heater Temperature Control

– Main Engine F.O Supply Line Pressure Control

– F.O Setting Tank Temperature Control

Specification

Type | Direct | Balance | Pilot |

Actuator | Heat Sensor | ||

Applicable Fluids | Steam, Hot Water, Thermal Oil | ||

Applicable Press./Temp. | 20 kgf/㎠ / 220℃ |

|

|

Material (Body / Trim) | Ductile Cast Iron, Bronze, Cast Steel / Stainless Steel | ||

Size | 15 ~ 25 mm | 32 ~ 50 mm | 65 ~ 125 mm |

Accessories (Option) | ● Heat sensor ● By-Pass Handle(Option) | ||

♦ JIS, DIN, ANSI design is applicable.

♦ Class Application : BV, LR, ABS, DNV/GL, LINA, KR, NK, CCS

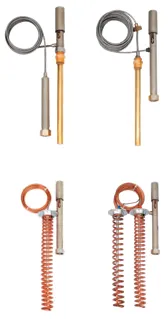

Heat Sensor

Application

Temperature Control Valve

– Direct Acting Type

Specification

Type | Bar Type | Coil Type |

Applicable Fluid | Water, Oil | Air, Gas |

Adjust Temp. Range (℃) | 0~60, 50~110, 80~140 | -20~60, 20~80 |

Capillary Tube Length (m) | 3, 5, 7, 8 ~ 15(Option) | 5(P)+7(S), 7(P)+10(S) |

Accessories | ● Sensor Pocket | – |

3Way Temperature Regulating Valve

Application

Engine Room

– Purifier F.O / L.O Heater Temperature Control

– Main Engine F.O Supply Line Pressure Control

– F.O Setting Tank Temperature Control

– Air Compressor Cooling Fresh Water Temperature Control

Specification

Type | Wax Element Control Type |

Applicable Fluids | Water, Oil, Liquid |

Applicable Press./Temp. | 20 kgf/㎠ / 220℃ |

Differential Pressure | 3.0 kgf/㎠ |

Operation | Dividing / Mixing |

Material (Body / Trim) | Ductile Cast Iron, Bronze, Cast Steel / Stainless Steel |

Size | 45 ~ 150 mm |

Accessories | ● Manual Lever(Option) |

♦ JIS, DIN, ANSI design is applicable.

♦ Class Application : BV, LR, ABS, DNV/GL, LINA, KR, NK, CCS