Cocks and valves are designed to control or interrupt flow. This is done in cocks by rotating the plug, and in valves by lowering, raising or rotating a disc in relation to a seating surface or by controlling the movement of a ball. These fittings have bodies furnished with flanged or screwed ends (or ends prepared by welding) for connection to the joining pipes.

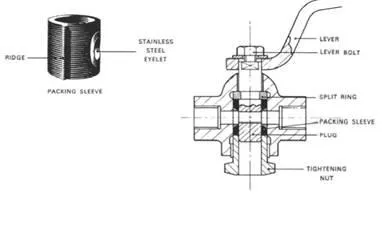

Cocks:> A cock may be straight-through, right-angled or open-bottomed as required by its situation in a pipe system. Its plug may be tapered or parallel with tightness achieved by lapping in or by resilient packing material (Figure below) often in the form of a ready made sleeve.

In machinery spaces, the short sounding pipes for fuel or lubricating oil tanks, must be fitted with cocks having parallel as opposed to tapered plugs. This, together with the requirement for weighted handles which will automatically close the cock when released, is for safety. Tapered plugs, when tightened to hold the cock open for sounding and then forgotten, have contributed to fires when tanks have overflowed. Boiler blowdown cocks on the ship's shell, are constructed so that the handle can be removed only when the cock is closed.

Figure : Example of a sleeve-packed cock (Richard Klinger Ltd)