Piston Skirt, Piston Rod and Trunk Piston

Piston is an important part of the combustion chamber of a marine engine which converts the gas force into mechanical power by reciprocating motion.

Piston skirt, piston rod and trunk piston are three components of the piston arrangement in marine diesel engines. In this article we will learn about each one of them

Generally two types of piston arrangements are used:

· Crosshead Piston: Comprises of Piston crown, Piston skirt and piston rod(used in large two stroke engine) which is connected to crosshead functioning to transfer the side thrust to the engine structure

· Trunk Piston: Comprises of piston with elongated skirt to absorb the side thrusts and attached to the connecting rod by small end rotating bearing (used in small 4 stroke marine engines).

Piston Skirts

Piston skirt is fitted in both two stroke and four stroke engines. It has different function for different engines. In large cross head two stroke engines with uni-flow scavenging these skirts are short in length and are fitted to act as a guide and to stabilise the position of the piston inside the liner. It is generally made of cast iron. The diameter of the skirt is usually kept slightly larger than that of the piston. This is done to prevent damage to the liner surface due to the piston movement.

Soft bronze rings are also fitted in the piston skirts. These bronze rings help during the running-in of the engine, when the engine is new, and can be replaced if necessary.

In two stroke engines having loop or cross scavenging arrangements the skirts are slightly larger as these helps in blanking off the scavenge and the exhaust ports in the liner.

Material of Skirt:

It is generally made of nodular cast iron which have the following properties:

· Self-lubricating

· Superior wear resistance

Piston wear ring: It is a ring made of soft bronze alloy with lead, which is fitted in the piston skirt. They have the following functionality:

· It has a low frictional characteristics

· help during the running-in of the engine, when the engine is new, and can be replaced if necessary

· Prevents the high temperature wall (upper side) of piston to directly come in contact with liner

In four stroke or trunk piston engines the skirt has arrangement for gudgeon pin, which transmits power from the piston to the gudgeon pin or top end bearing. As there are no cross head guides in four stroke engines, these skirts help in transferring the side thrust produced from the connecting rod to the liner walls.

Inspection – Following things to be checked when inspecting the piston skirt:

· Carbon deposit

· Wear and rubbing mark

· Scuffing damage in the wear ring

· Check gudgeon pin boss for crack or/and deformation in trunk piston skirt

Piston rods

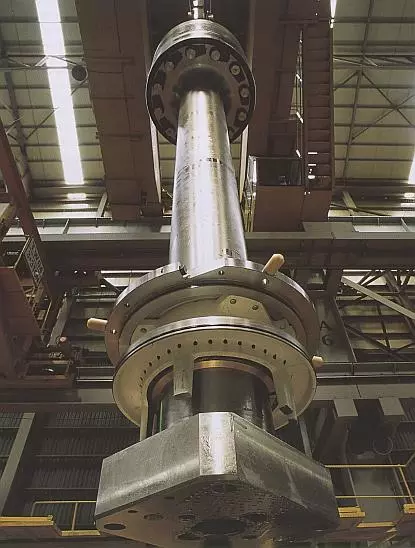

Piston rods are generally found in large two stroke engines. Piston rods help in transmitting the power produced in the combustion space to the cross head and the running gear of the engine.

The lengths of these rods depend on the length of the engine stroke and the manufacturers design. The top end of the rod is flanged or attached to the underside of the piston and the bottom end is connected to the cross head.

The piston rod passes through the piston gland or stuffing box so the rod should have smooth running surface and low coefficient of friction.

Important Function of Piston rod:

· The gas force acting on the top of piston crown is transmitted to the piston rod by internal mechanism avoiding possible distortion of the ring belt.

· For cooling of the piston the rods consists of two through and through concentric holes. These holes are for supply and return line of cooling oil.

Forged steel is used Material of Piston rod:

to make piston rod which has following property:

· High strength than cast steel

· Better surface finish

Inspection – Following things to be checked when inspecting the piston rod:

· Wear and rubbing mark due to stuffing box gland

· Scratch or dent mark due to improper handling

· Ovelity of the rod at various positions

· Surface shine of the piston rod (measure surface roughness in Rs)

Trunk Piston

Trunk piston is a term usually given to the pistons in four stroke medium speed engines. These pistons have composite design which comprises of thin sectioned alloy steel piston crown along with aluminum alloy skirt. These pistons are light, strong and rigid in construction and are capable of resisting high temperatures and corrosion.

The piston is forged and the space inside is provided for arrangement of cooling spaces, which is done by cooling oil. The skirt consists of space for gudgeon pin which transmits power to the connecting rod. The skirt also helps in transferring the side thrust produced by the connecting rod.

The piston consists of rings grooves for fitting piston rings. The landing of piston rings is hardened and plated with chrome to reduce wear. The top surface of the crown may be recessed to provide clearance for inlet and exhaust valves. Compression rings are fitted in the crown and are generally plasma coated whereas other rings are chrome plated. The oil control ring is fitted in the top of the piston skirt.

Since the piston rod is not used, the height of the engine is considerably reduced when using trunk piston but there is no separation between liner/piston assembly and crankcase, which may lead to contamination in case of blow-past.

Material: The trunk piston comprises of piston crown and elongated skirt.

· Crown is made up of heat resistant forged steel alloy including chromium, nickel and molybdenum for heat and corrosion resistance without compromising on strength

· Skirt is made up of nodular cast iron or forged silicon aluminium alloy which has the advantage of being light, with low inertia, reducing bearing loading.