Atmospheric Pollution Causes Deterioration of Sweeteners of Treats and Decreases Competitiveness in the Food Industry of Coastal Baja California, Mexico

Most pollution at sea, in coastal areas and around beaches etc. takes the form of oil spills. This has led to several natural disasters resulting in the death of fish, a loss of revenue from tourism in some areas, and economic losses in the food industries located in coastal zones. The contamination affecting the food industry in these areas causes the deterioration of food products, is injurious effects to health and the damaged food products are consigned to wastage. The visual appearance of the final product represents one of the key factors of food quality and this can be affected and altered by atmospheric pollution generated by contaminantspollutan sulfur in Tijuana city, located on the coast of Baja California. In addition to these chemical agents that modify the nutritional properties of the pigments that are added to food products in this marine zone of the Mexican Republic, variations in climatic factors such as temperature and humidity are also considered in this study. In the major food companies that manufacture sweetened breads, pastries and sweets in this Tijuana cihat fabricate lower quality sweetened breads and foods are occasionally sometimes made as a result of the deterioration of certain types of artificial pigments that are very sensitive to light, heat, and mainly acidity [1]. An investigation was carried out to discover the causes of the loss of quality in aspects of the production process such as candy coating.

MANUFACTURING PROCESSES AND QUALITY FACTORS IN THE INDUSTRY

Manufacturing is defined as a set of organized and programmed activities for the transformation of materials, objects or services into articles or services useful to society. The manufacturing engineer utilizes industrial processes as the mechanism for the transformation of materials into useful items for society [2]. It is also seen as the structure and organization of actions that allow a system to accomplish a certain task. In the vast majority of cases, in order to obtain a particular product it will be necessary to perform a lot of individual operations — depending on the scale of observation — including operations from the extraction of the natural resources necessary to sell the product to those involving a job with a particular machine or tool. A manufacturing industry is present under all types of economic systems. In a capitalist economy, manufacturing is usually directed toward the mass production of products for sale to consumers at a profit. In a collectivist economy, manufacturing is directed by a state agency. In modern economies, manufacturing runs under some degree of government regulation [3]. Modern manufacturing includes all the intermediate processes required in the production and integration of the components of a finished product. The industrial sector is closely related to the engineering and industrial design sectors. The process may be manual or may employ the use of machines. For higher volumes of production, the technique of the division of labor is utilized, whereby each worker performs only a small portion of the whole task. This specialization saves time and money and results in a greater speed of production. Although craft production has been part of humanity for a very long time (since the Middle Ages), it is generally considered that modern manufacturing emerged around 1780 with the advent of the British Industrial Revolution, expanding thereafter throughout continental Europe, then to North America and eventually to the whole world [4]. Manufacturing has become a huge part of the economy of the modern world. According to some economists, manufacturing is the sector that creates wealth in an economy while the service sector tends to be a consumer of wealth. The process of quality control involves applying quality manufacturing processes to a product.

Techniques used are those such as Statistical Process Control (SPC) applied to samples of the product. By closely controlling the process, the risk of the product being of poor quality is greatly lessened. This technique has the advantage of lower losses through preventing the occurrence of defective product and the associated generation of higher costs. The quality control process operates under the supervision of the quality control department. For some time now, there have been a lot of manufacturing systems based on quality assurance rules [5]. The transition to the serving of a customer in base in organizations, has led to fundamental changes in manufacturing practices. For this reason, the changes have been especially evident in areas such as product design, human resource management and supplier relations. For example, in product design, activities are now integrated into narrow marketing operations, engineering and manufacturing. The practice focuses on empowering employees to collect and analyze information, taking crucial operational decisions and accepting responsibility for continuous improvement, thus spreading the responsibility of the quality control department across in the enre manufacturing processes. The providers have become partners in product design and manufacturing efforts. In this research project, which was developed in the food industry, the manufacturing process is evaluated in the area where the sweetener is applied to the final product of a sweetened bread. The operations in this part of the process are performed using specialized activities, which are regulated by certified companies and government authorities. The proper adherence to the guidelines for the use of bread sweetener results in the presentation of an optimal product to the consumer [6].

ENGINEERING AND COMPETITIVENESS

Creativity is one of the most valued and demanded qualities by companies in the field of industrial engineering, due largely to the competitiveness of the market. The application of creative thinking to the design process of an engineering project gives added value in each and every one of its phases [7]. To carry out this fusion of creativity and engineering, we need to redefine traditional project methodology. In teaching the concept of creative engineering, the transition of the systems must be taken into account, along with other important factors related to industrial engineering and competitiveness. This approach is a suitable one to promote the genduction of thee thsired quality and quantity of goods in the time required, usi the generation of new ideas, methods and processes available to the industry with a special emphasis on engineering and competitiveness. Product engineering serves as a model to help us better understand about the to use the most creative and innovative engineering methods along with traditional values. Competitiveness is a clear example of the synergy produced between engineering and creativity and is apparent through the project results [8].

INTERNAL AND EXTERNAL FACTORS IN THE COMPETITIVENESS OF THE INDUSTRY

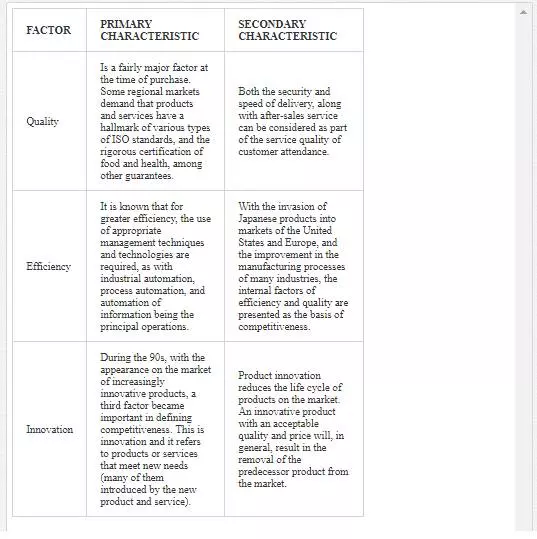

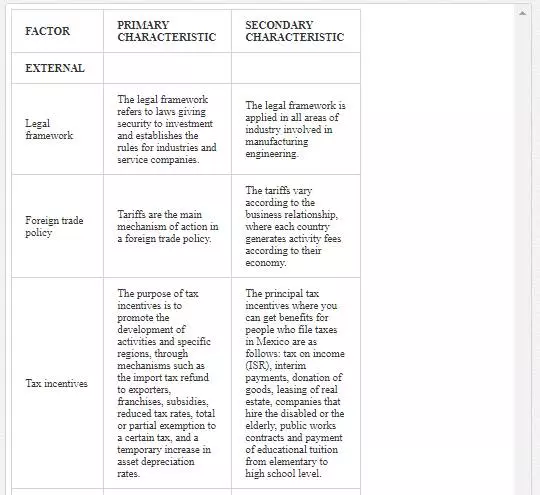

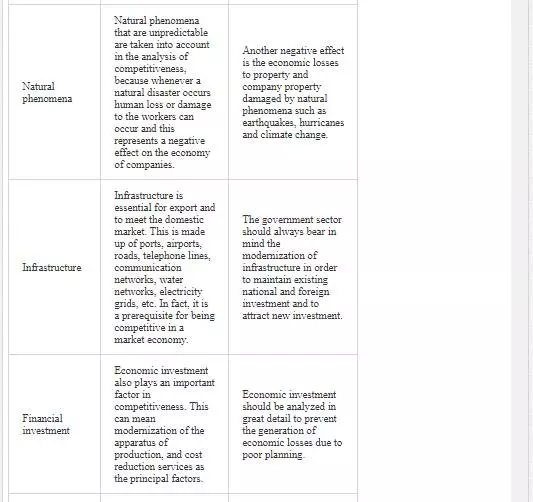

The factors that define the degree of competitiveness of an industry and in engineering services in manufacturing can be classified as internal and external factors. The internal factors are those that directly depend on the organization and on which the organization can act [9], while external factors are those that do not depend on the organization. Internal factors can be grouped into three areas: quality, efficiency and innovation as mentioned in Table 1.

Constant competition and the drive for excellence in new products make the integration of the manufacturing process and automatized systems a necessity. In the process of product innovation, specialized simulation software allowing for repeated testing has generated optimal systems for the development of parts and new products with specialized parameters. Certainly, the development of many systems mentioned in this section relies on other areas of knowledge. For example, expert systems require the knowledge and experience of specialists in the area of study in question. Engineering support systems require the participation of engineers and experts in their conception and development; in many cases these systems are developed by highly qualified personnel and both undergraduate systems and computer systems [10].

RELATIONSHIP BETWEEN ENGINEERING, COMPETITIVENESS AND EDUCATIONAL ACTIVITIES

Working on such projects can help to engage the different learning styles of young people and educators have an obligation to stimulate student curiosity in the operation and efficient use of matter and energy. Therefore, physics should be shown as a science that is essential to the scientific and technological progress of mankind and thus contributes to improving the quality of life.In an analysis of a study into the relationship between engineering and competitiveness, it is stated: "When I read, I'm imagining what is described in the book I'm studying” [11]. This makes me think that the student must remain permanently connected to the physical subjects presented by the teacher, and what better way to stimulate them than with a didactic prototype as shown in Figure 1. Vicarious learning is something that occurs through the observation of others. People and animals can learn just by watching another person or animal, and this behavior challenges the idea that cognitive factors are not necessary to explain learning. If people learn by observing, then we can focus their attention by creating images that to promote remembering, analyzing and decision making to affect learning as is presented in Figure 1. The skills and attitudes of competitiveness are developed when working in an environment in which a suitable nade and orderly effort coexist. The trust between students creates an interaction that motivates them towards project the comof projects, producing in them a proactive change. Engineering activities, especially ones related to topics of physics and chemistry, are in essence a practical science related to the use of many concepts and formulas. There is no single constructivist theory of learning. Most theories in cognitive science include some form of constructivism, as they believe that individuals construct their own cognitive structures as they interpret their experiences in particular situations. The group dynamics used to better understand the relationship between engineering and competitiveness, refers to the set of forces —movement, action, change, interaction, reaction or conversion — that operates in a particular group for the duration of their relationship, giving a style or personality to that group and making them behave in that particular way. The reciprocal interactions of these forces and their result on a given group are its dynamics [11]. Finally, communication skills and student attitudes will be developed when working in an environment of appropriate adequate planning rderly effort.

COMPETITIVENESS IN THE FOOD INDUSTRY

The study of the influence of competitiveness in the business world is a matter of ongoing discussion, especially in the food sector where there is a huge number of companies worldwide — a significant percentage of the total of which are manufacturers of sweetened breads and treats. Some companies are internationally recognized, but those with smaller economic resources are in a highly competitive part of the market, and to some experts this is considered to be the limiting factor to growth and competitiveness [8]. The findings of this study include some interesting trends, although they lack certain stan information and more accurate statistical data. The industries of this type, is related with sustainable competitive advantages and managed by companies that are analyzed in the study as vectors of competitiveness. The three vectors considered are: technological innovation, internationalization and funding.

FOOD INDUSTRY

Food processing includes the methods and techniques used to harvest raw materials using clean components and then transform them into commercial food products for human consumption componto produce commercial of different ways in which food can be produced. The manufacture of one foodstuff could take days depending on customer specifications and conditions for the design capacity of the industrial plant in question [4]. The production line is used when the market size is large and where is a range within a selection of products. A large number of the same goods to be produced make it possible to use simple methods that require a complex manufacturing process. All methods include an estimation ng of the number of customers who want to buy the food product in question. Mass production is used when there is a mass market for a large number of identical products, such as chocolate bars, ready meals and canned foods. The product passes from one stage of production to another along a production line. All components of the product are specified by the customer, who chooses them based on their structure, taste, smell and other characteristics of the food. An extensive network of global transportation is required by the food industry to market its numerous products. These include suppliers, manufacturers, warehouses, retailers and consumers.

There are also companies that add vitamins, minerals, and other necessary requirements to the product to replace cover those lost during manufacturing process. The wholesale markets for fresh produce have tended to decline in importance in Latin America and some Asian countries as a result of the expansion of supermarkets that buy directly from farmers through preferred providers, instead of going through markets. The constant and uninterrupted flow of goods from distribution centers to store locations is a critical link in the operation of the food industry. Distribution centers operate more efficiently; performance can be increased, costs reduced and advantage taken of better work if the right steps are taken when a material handling system is set up in a warehouse. With large parts of the population concentrated in urban areas, food shopping is growing and is a basic human requirement according to the nutritional process. This is a relatively recent development that has taken place mainly in the last 50 years [4]. The supermarket is the defining element of sale in the food industry, where tens of thousands of products are gathered in one place and are in continuous year-round supply. Restaurants, cafes, bakeries and mobile trucks are also ways to reach consumers of food. Food prepare another area where the changes in recent decades have been spectacular. The food industry sells fresh products and the bakery industry in particular needs a large amount of raw materials and ingredients to make the products and get them to their consumers. One type of important ingredient is color pigment — used to for better improve thrion and appearance of the product [12].

STAGES IN THE FOOD INDUSTRY

The food industry uses a variety of processes in the manufacture of food products with advanced technologies utilized in those production processes. This is in order to create the optimum conditions for customer satisfaction, hygiene and to lower costs in all types of food processing technologies such as those used in sweetened bread and treats. The main stages in the manufacture of foods are [13]:

a. Use of technologies for the monitoring and storage of food and raw material for processing.

b. Evaluation of the types of ingredients for food preservation in the company and outside of it.

c. The use of both simple and complex methods in the processing of food according to the specific conditions requested by the client.

d. Monitoring of the quality of the final product using specialized methods and techniques to suit the needs of consumers.

e. Storage of finished products in specific areas with high levels of security.

f. Analysis of food waste or chemicals used in the process for the manufacture of foodstuffs.

Heavy industry, such as the metals industry has been a factor in the pollution of the coastal zones and was studied to better understand the effects of this industry and the damage it causes to the company being evaluated.

SWEETENERS AND FOOD

Sweeteners are additives such as coloring pigments or substances that impart color when they are added to foods or beverages. They come in many forms, consisting of liquids, powders, gels and pastes. Sweeteners are used in the commercial production of food and domestic cooking. For your safety and general availability, the dyes are also used in a variety of non-food applications including cosmetics, pharmaceuticals, craft projects and medical devices4. People associate certain colors with certain flavors, and the color of food can influence the perceived flavor in many respects. Sometimes the goal is to simulate a flavor that is perceived by consumers as natural, such as adding red coloring to candied cherries (which would otherwise be light brown), but sometimes it is for the purpose of cosmetic appearance, such as in Heinz ketchup green tomato sauce, launched in 1999. Flavor additives are used in foods for many reasons, including [14]:

a. To offset color loss due to the exposure to light, air, extremes of temperature, moisture and storage conditions.

b. For the correction of natural variations in flavor, to enhance colors that occur naturally, and to provide a variety of colors to colorless substances and foods to give them a better appearance.

Flavor and color additives are recognized as an important part of many of the foods that we eat. The flavorings and sweeteners used in the food industry are tested for safety by various agencies around the world, and sometimes the different bodies have different views on food safety with respect to the color additives used [8]. In the United States, the regulatory body is the Food and Drug Administration (FDA) and they approve which additives can be used in foods, drugs and cosmetics — as synthetic food colors do not exist in nature — while in the European Union, all additives, both synthetic and natural, have to be approved for use in food applications. The best known food flavorings and colorings are turmeric and lutein. Most countries have their own regulations and list of food dyes that are approved for use in various applications, including that for the maximum daily intake [15]. The certified flavors and colors are synthetically produced and widely used since they impart a strong uniform color, and are less expensive and more easily mixed to create a variety of hues and flavors. Certified flavors and colors in foods generally do not add undesirable flavors to those foods, while pigments derived from natural sources such as vegetables, minerals or animals are exempt from certification. Additives derived from natural flavors and colors are generally more expensive than certified synthetic colors and may add undesirable flavors to foods.

Prime examples of exempt colors are annatto extract, beet, caramel, beta-carotene and grape skin extract. The natural colors of food take on a variety of shades and hues [6]. Around 80% of what we taste is detected as coming from the sense of smell. The trigeminal nerve is responsible for detecting irritants that enter through the mouth or throat and can sometimes determine flavor. The taste of food is not just a concern for cooks, but is also a scientific challenge for the food industry. Flavorings and seasonings, whether natural (spices) or artificial (E numbers), are used to highlight or modify flavors. An increasing number of natural food colors are being produced commercially, in part due to consumer concerns surrounding synthetic dyes. Examples include candies made with caramelized sugar, annatto – a reddish-orange dye from the annatto seed, chlorophyllin – a green dye made from algae, chlorella cochineal –, red dye derived from the insect Coccus dactylopius, Betanin extracted from beet, curcuminoids from turmeric, carotenoids from saffron, paprika, lycopene, elderberry juice, a green dye from Pandanus amaryllifolius, and a blue food coloring from the butterfly pea Clitoria ternatea. These residues often remain in the finished product, but it is not a legal requirement for this to be declared on the product packaging as the residues are part of a group of substances known as carry-over ingredients. Because of their organic nature, natural food colors can sometimes cause anaphylactic shock and allergic reactions in susceptible individuals. Coloring agents known to be potential hazards include annatto and cochineal carmine [17].

EFFECTS OF AIR POLLUTION ON THE PROPERTIES OF PIGMENTS

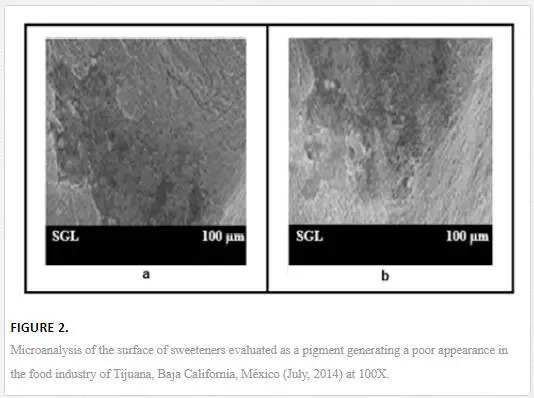

The presence of contaminants in the atmosphere is of great concern due to their varied effects according to humidity and temperature. For example, in some seasons contaminants can cause the deterioration of foodstuff and thus change the properties of the pigments used in them [18]. These properties can result in a loss of appearance in the food, even when packaged and packed using a bleaching process. Despite the enforcement of quality standards in the environments in which of foodstuffs are manufactured, and even in systems with robust quality control measures in place, certain types of pollutants were present within the industry where the study was conducted. There are various types of sources that emit these pollutants into the atmosphere, mainly located in the coastal city of Tijuana, which suffers from the emission of sulfides from cars and the thermoelectrical plant that supplies Tijuana with electricity. The highest levels (at 70% Relative Humidity (RH) and 25 °C), that are presented r the majority of the year, cn change the properties of pigments used in the manufacture of sweetened breads and treats so that sometimes the pigment does not properly adhere to the surface of the bread. Sometimes the pigment drops off, or in the process of marketing and transport the external structure of the food product is modified resulting in a poor appearance and the food in question being returned to the company that manufactured it, generating economic losses as shown in Figures 1a and 1b. As shown in figure below, the dark sections are parts of pigment which are not properly attached to food products resulting in economic losses as it becomes necessary to market them at a lower price to the consumer. This decreased the competitiveness of the industry in the period evaluated, and is presented in Figure 2. In the zones with a dark color, the figure shows the deterioration of the sweeteners in bread, where a layer was peeled off the bread, resulting in a damaged appearance and a lower quality product. Specialized persons and managers in the food industry where this phenomenon was evaluated, considered that it was necessary put products made with such defects into the trash resulting in economic losses. This analysis was represented of the study evaluated in the company mentioned.

PETROLEUM AS A POLLUTANT IN SEAWATER

In recent decades, oil has played a major part in the global economy, contributing to socio-economic and technological development in many different cultures and countries. Oil only occurs in certain parts of the planet and excavations and drillings are restricted to these areas. This leads to a search for the areas where oil is located and can be transported for processing to extract its derivatives. This transport is the main source of pollution and spills, sometimes resulting in small scale problems and sometimes in disasters on a much larger scale. The spill of this hydrocarbon usually occurs due to an accident or inadequate practice causing pollution to the environment and especially the sea. This affects the entire ecosystem in which the event took place and can catastrophically damage wildlife and fisheries produce, and the effects on the coast can become very persistent over time [19].

FOOD INDUSTRY OF THE COASTAL ZONES OF MEXICO

The main coastal cities in Mexico, with companies making products that are affected by the coastal atmosphere, principal in indoors of this companies; are Acapulco in Guerrero, Ciudad del Cabo in Baja California Sur, Ensenada in Baja California, Campeche City in Campeche, Mazatlán in Sinaloa and the port of Veracruz in Veracruz [20]. The principal products of these areas of Mexico are sardines, tuna, wheat and maize flours, and breads. In the coastal region of Baja California, a great quantity of tuna, bread, vegetables, and legumes are produced as the principal foods.

Methodology

The research was conducted at a company that makes flour for food products, with the low quality of defective products being correlated with the climatic factors of relative humidity (RH) and temperature as the most important aspects of the climate. A monthly evaluation of the manufacturing processes of the industrial plant being analyzed was made, and the indices of RH and temperature in each month of the evaluation period. Other factors evaluated were the physicochemical surface properties of the pigments using SEM techniques. In each month of the period from 2012 to 2014, 100 food products were analyzed. Statistical correlation was performed using the Mat Lab program [21]. Both ISO [22, 23] and ASTM [24] Standards were also used and the study was performed in three steps as described in the following information:

a. Analysis of climatic factors. This took place in indoor locations of the food industry mentioned above, specifically in the areas where the use of sweeteners in manufacturing processes of the bread occurred, in order to determine the negative effects of temperature and relative humidity in the adhesion of sweeteners used in the bread. The two principal climatic factors mentioned were evaluated in hourly, daily, weekly, monthly, seasonal and yearly periods using an Acurite hygrometer coupled with a thermometer.

b. Evaluation of air pollution. This step was used to determine the principal air pollutants causing a negative effect in the process of adhesion of sweeteners used in the bread, and the level of concentration of the chemical agents obtained in the analysis. The air pollutants were evaluated in hourly, daily, weekly, monthly, seasonal and yearly periods, using specialized air pollution monitoring equipment including Technique Sulfating Plates (TPS) and a Gas Alert Micro 6 portable monitor.

c. Microanalysis. This was undertaken using SEM analysis to determine the principal chemical agents of air pollution that were present in the manufacturing process.

Hypothesis

Before undertaking this study, a prediction was made that atmospheric pollution would have a negative effect with respect to the use of sweeteners in treats and that this would lead to a deterioration of product quality and economic losses.

Objective

Determine exactly the ranges of pollution and climatic factors that cause the non-adhesion of sweeteners in the bread.

Results and discussion

The principal airborne pollutants detected in this investigation were in the gaseous and solid state, comprising mainly small dust particles of hydrogen sulfide (H2S), sulfur dioxide (SO2) and nitrogen oxides (NOX)m and these were able to penetrate to the interior areas of the industrial plants. These chemicals caused unfavorable indoor environments in the evaluated company evy entering through air inlets in the filter systems, as well as through holes and cracks. In combination with moisture and temperature they caused damage to the manufactured foods. The difference between a food in good condition and a food with unbound pigment sections is shown in the results obtained.

ANALYSIS OF CLIMATIC FACTORS

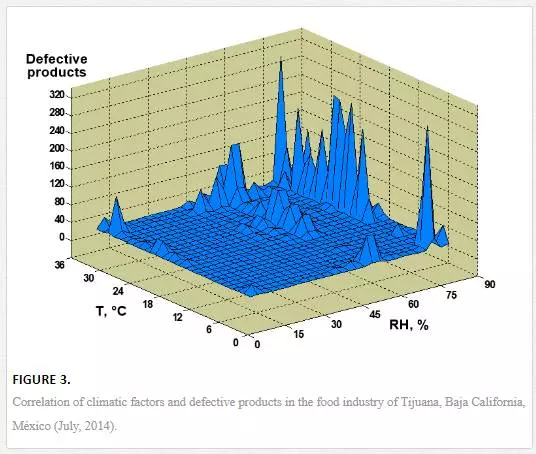

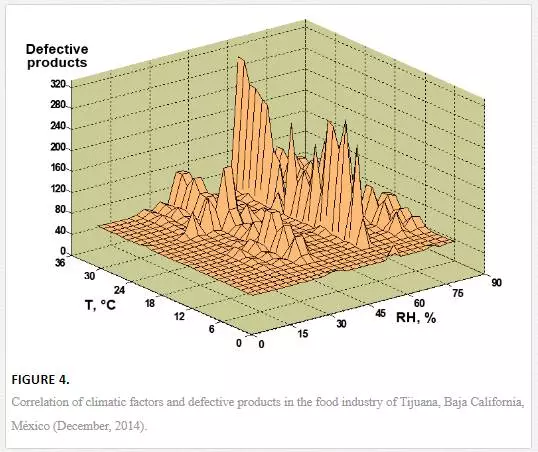

Climatic factors are important in the production and manufacturing processes of the food industry, where high or low levels of relative humidity and temperature can result in a negative effect on products as the sweeteners can be added at some times but not at others. This is a concern to specialized people and managers, who consider that the products manufactured need to be put in low quality sections or may even need to be put in the trash. These low quality products are considered to be defective and may require some extra work to rectify problems with them. This in turn makes it necessary to pay workers overtime and this needs to come from the budget of evaluated company. Also generated space in some areas of the food industry analyzed and this represents an economic spending. On the other hand, we also see a loss of time in the delivery process to the customer, which can generate costs not anticipated at the inception of product operations, in addition to potential legal battles and lost customers. Figures 3and 4 show information representing the correlation of the principal climatic factors of RH and temperature, with the defective products manufactured in the months of July 2014 (Figure 3) and December (Figure 4). This caused a negative effect on the financial operations of the food industry evaluated. This company is located in Tijuana, Baja California, in northwest Mexico, near of the border with the United States. This area of Mexico is a coastal zone, with changes in the levels of the climatic factors mentioned, principally in the periods of the presence of the phenomenon called the Santa Ana Winds at the start of the spring period (the last days of March and the first days of April) and in the autumn (the last days of October and the first days of November) of each year. In Figure 3, the analysis of July of 4 showed the high quantity of defective products, with 320 as the maximum and values of relative humidity and temperature around 75% and 35 °C respectively. The minimum number of defective products was 12, with values of the climatic factors mentioned above of 15% and 35 °C. Figure 4 represents the analysis of December 2014 where the maximum value for the quantity of defective products was 320 with values of 65% and 35 °C relative humidity and temperature respectively. This was causing the observed effect of the occasional detachment of the sweeteners in the bread. To improve the manufacturing processes of the sweetened bread it was necessary to aveexert control over the climatic factors through the use of an automatic system proposed and designed by the researchers of this study. This automatic system works through the detection of both low and high humidity and temperature together, to trigger the operation of fans and an automated irrigation system within the manufacturing area without affecting the manufactured products.

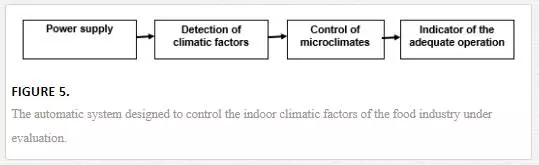

The automatic system designed to control the climatic factors is discussed below. The system was designed to consist of simple steps and the control device had to have a cost of less than 100 pesos, which is already assessed in companies with improving productivity performance that keep companies from installation cost. The automatic system consists of several simple steps shown below in a block diagram and then explained theoretically (Figure 5):

CORRELATION OF AIR POLLUTION WITH THE DETERIORATION OF PIGMENTS

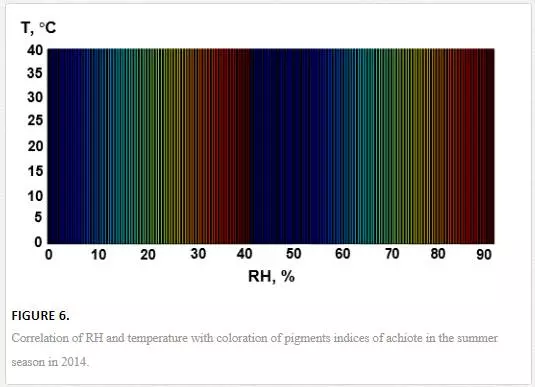

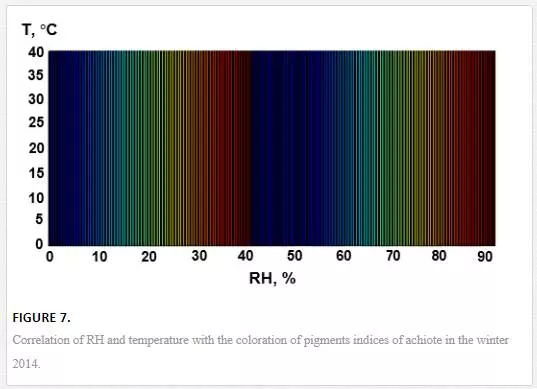

The properties of pigments vary according to the variations in relative humidity and temperature levels as indicated by color in Figures 6 and 7. Red indicates high levels of color loss through fading, followed by yellow, then the light blue and ending with dark blue. All levels are derived from the correlation of the values of relative humidity and temperature. The coloring pigments are also shown along with the ranges in which humidity can have a negative effect and therefore when to take the necessary measures. Various pigments such as caramel, annatto, chlorophyllin, and saffron used by the company where the study was conducted were analyzed. In the winter season, more risks occurred than in the summer but this does not mean that the pigments were fading quickly, but a simulation indicated the possibility that this will occur. In both figures, the colors define the defects in according to the events occurred and the possibility to be considered as a defective products. In Figure 6, blue appeared the most times, indicating that the manufacturing processes was adequate, with some parts of the figure showing green and yellow colors representing products with some defects. Green represents a quality of product that can be considered as adequate while a yellow color indicates a product outside of quality tolerances and considered to be defective. Red represents a low level of quality. Both analyses were made in 2014.

Figure 7 shows the same process as Figure 6 but with fewer blue zones and more green, yellow and red zones of the same size.

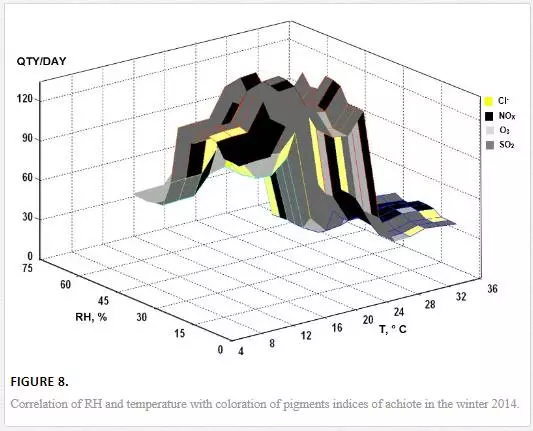

ANALYSIS OF PRODUCTIVITY CORRELATED WITH ATMOSPHERIC CORROSION

The productivity of a company is very important in the fight to keep it competitive in the world market and to maximize profits. This represents the adequate index of the industrial operations in the manufacturing areas. The productivity yield is affected by with climatic and atmospheric parameters, where air pollution has a negative effect on the adhesion of the sweeteners used in the bread. Figure 8shows the correlation of climatic factors related to the pollution agents in the indoor area of the food industry, and the quantity of products manufactured by day. The chemical agents were evaluated using colors to represent the level of negative effect on the yield of sweetened bread products manufactured. This analysis was made in the winter when the index of RHrela higher as this was the parameter with the most significant effect on the deterioration of the bread. The air pollutants with the most significant effects were as sulfur dioxide or sulfur derivatives followed by ion chlorides, nitrogen oxides and ozone, that shows the graphic with the colors. The sulfurs and ion chlorides were present in the low productivity zones of the figure. In change where were presented the levels of nitrogen oxides and ozone, productivity was high. Relative humidity Handhith the most significant effect on productivity when they were in the ranges of 50% to 75% and 20 °C to 35 °C respectively.

SEM EVALUATION

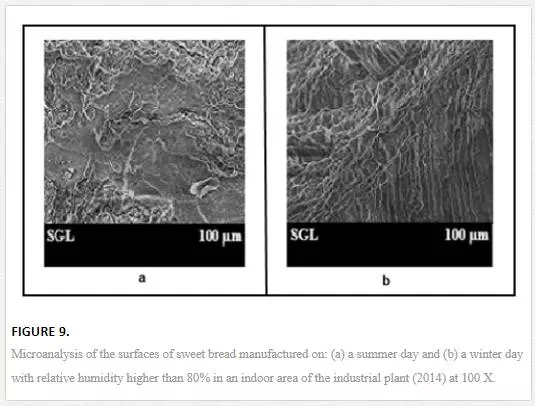

SEM techniques were used to make a microscopic evaluation of the defective and non-defective breads in order to compare the manufacturing processes using the automatic system with that where the climatic factors were not controlled. Figure 9 represents two daily evaluations of the deterioration of the sweetened bread on a summer day (July) and a winter day (December), where the relative humidity was higher than 80% and the temperature between 20 °C and 30 °C as is common in winter in Mexican cities. Figure 9 shows two examples of pigments in manufactured foods with good color in section (a) and spoiled food color level, causing discoloration and (b) food products deteriorated in different days of the year.

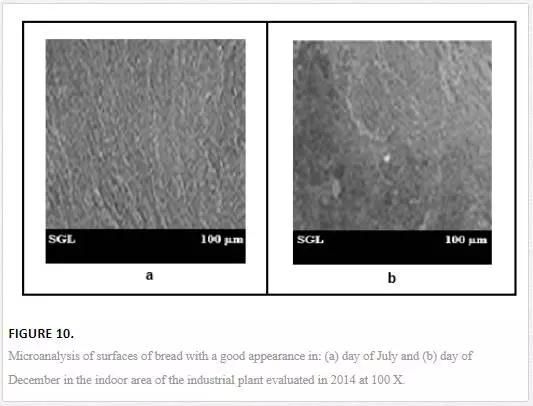

In change in figure 10, was made an evaluation with the use of the automatic system representing an improvement in the sweetened bread with better adhesion of the sweeteners as shown in a layer which appears smoother. Figure 10 shows a microanalysis of the appearances of sweet bread with ideal adhesion of the pigments in both summer and winter seasons. In both seasons the formation of the sweeteners was uniform and was considered to be of a high level of quality. The automatic system was very helpful in obtaining products with a good appearance that would therefore appeal to customers. This system controlled the relevant climatic factors and sent an electrical signal when the level of air pollutants was higher than that of the air quality standards, with the inefficient operation of the electronic device that make the function of control.

Conclusions

General corrosion is the cause of the destruction of most of the materials used in the food industry. The development of corrosion processes in the materials used to make food products leads to the modification of their properties which has a subsequent adverse effect on the manufacturing processes, particularly in the case study of the company that allowed us to investigate their marketed foods. Pigments used as food additives are very important in producing foods with an attractive appearance and that enable quick and easy marketing in the region, before some changes in these coatings start to be observed. Moisture was the factor that had the most significant effect on this process and a humidity control system — which has already been tested in other companies — is recommended. Temperature had an effect to a lesser extent, but it is still important to consider temperature, because if the humidity varies then the characteristics of the temperature change too. Sometimes the pigments have good adhesion and these products have the quality required in this type of food. At other times the sweeteners and pigments deteriorate easily, and some people consider that fresh bread made on the coast of the Baja California area is of low quality. In support of this, a study was done on pigments quickly losing their sweetener properties through variations in climatic factors such as RHrand temperature. Air pollution correlations were developed, showing the effect of levels of rH Hnd temperatures greater than 80% and 10 °C in the winter season, mainly in the months of December and January in Tijuana city.