Use of Overspeed Regulatory Mechanism in Ships

How do you check that the speed of the main marine diesel engine does not shoot to dangerous limits in certain situations?

We have learned about the relay governors used in ship auxiliary engines whose main purpose was to control the speed variation under changing loads as well as to act as a safeguard in case of lubricating oil failure to the engine. There might be conditions when the governor needs to regulate the engine speed immediately not only in case of lubricating oil failure but also due to over speeding as that may cause extensive damage to the engine in emergency situation. One such situation could be that the propeller of the ship might get lost due to extremely rough weather or some other problem.

Overspeed Governors

Overspeed governors are the answer to the problem in such situations and act to control the speed if there is suddenly a great variation of speed of the order of about 10% of the running speed.

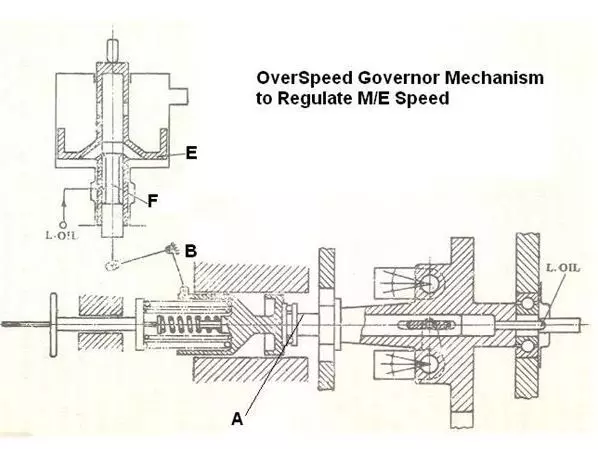

The working diagram of such an overspeed governor is shown here. If you notice closely it is not much different from that of a governor used to control the auxiliary engine speed on ships. But there is one main difference though and that is that this type of speed governor does not come into action for minor variations of speed but only comes into action for a major variation in speed. Hence the difference lies in the basic design characteristics of the governor. The working of this device can be understood by following the logical steps of its operation as follows.

○ Let us suppose a ship is running and suddenly looses its propeller.

○ The speed would instantly increase due to decrease in load

○ This will be sensed by the flywheels and they will jump outwards

○ The thrust collar “A" moves forward and moves the linkage “B"

○ Servomotor slide valve “F" gets pushed upwards

○ The oil flowing under servo piston “E" gets affected

○ The fuel pump admission settings get lowered

Finally when the speed starts to decrease, the reverse process takes place unless normal speed is restored. Of course all this happens very quickly though it has taken a long time to describe.

Isochronous Mode

Governors used to control the speed of main marine diesel engines are normally run in the isochronous mode. This basically means that the speed of the engine would remain the same irrespective of changes in engine load. Of course there is a very small time period following a change in load when the governor stabilizes the speed to its original value and the speed can vary slightly during that period of time.

We also learnt about droop in our previous article and I would like to mention at this stage that although the main diesel engines could be run without droop known as zero droop settings, yet it is not advisable to run smaller generators associated with power generation with such settings. There should be a minimum droop associated in these mainly to achieve a smooth load division amongst these machines. We will discuss about load sharing in a separate article though.

Companies Making Governors

There are many companies which make governors for marine applications and one such company is known as Woodward Governor Company which is a niche company manufacturing governor units for all sorts of marine applications. In our next article we will study the working of one such actual governor in detail.