Ship's Boiler Steam Supply for Accommodation and Deck Equipment

Ships boiler steam supply for accommodation and deck equipment must be reduced in pressure before use. It is then used in the accommodation for heating and, by the galley for steam cleaning worktops / cooking utensils. Steam is also supplied to the deck to drive winches and anchor windlasses.

When I was a young engineer at sea serving on oil tankers; the mate on the bridge would phone down to the engine room and request steam on deck. This was used to drive the cable winches, anchor windlass steam engine, and supply the Butterworth Pump when tank-cleaning.

Steam is also supplied to the accommodation for heating and galley use; in both cases under reduced temperature and pressure.

Nowadays, steam is still supplied the accommodation and galley, but windlasses and winches are normally electric or hydraulically driven, depending on the type of vessel.

The following sections examine the use of steam; beginning with an overview of its supply and return system.

Steam - Supply and Return Overview.

Ships boilers operate at high pressure and temperatures, often supplying superheated steam to the main engines. Therefore the steam pressure has to be decreased and this is achieved by passing it through a number of pressure reducing valves and de- superheating if required. The de-superheater is a pressure vessel where condensate is sprayed into the superheated steam flowing through it, converting the superheated steam to saturated steam. The de-superheater is located in the ships boiler room.

When steam is required on deck; the drains on the steam driven components and supply piping on deck are opened and all steam traps checked to be operating correctly. Only then is the steam to deck isolating valve in the engineroom very slowly opened. This is particularly important after the system has been shut down during a long sea voyage and will prevent damage to the pipes and flange gaskets due to rapid thermal expansion and water hammer.

Steam is supplied to the galley for cooking and hot water and also supplied to and a heat exchanger for the accommodation.

A steam hot water calorifier in the engine room provides domestic hot water to the accommodation.

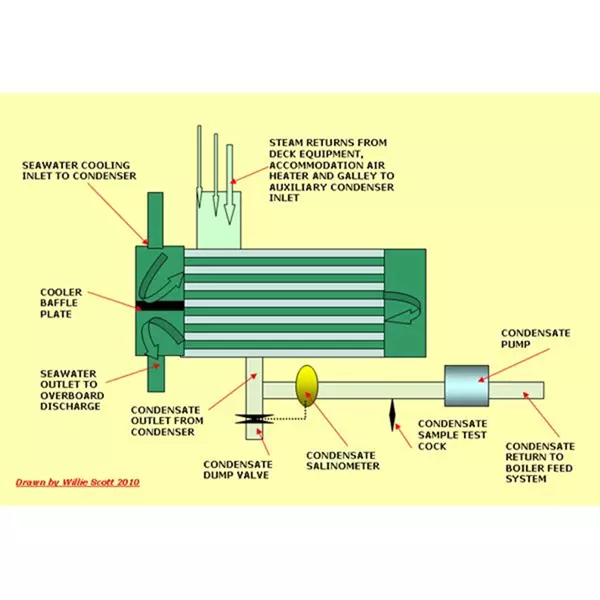

The steam from these components and functions is returned through piping back the engineroom auxiliary steam condenser. This is cooled by seawater and the resultant condensate returned to the boiler feed system.

This condensate from the auxiliary condenser is regularly tested for oxygen and acids content, and an on-line salinometer is normally fitted which dumps the condensate if the salt ppm is too high. These feedwater contaminates would corrode the insides of the boiler water tubes if allowed to enter the boiler water system. A sketch of an auxiliary condenser is shown below.

Steam Windlass

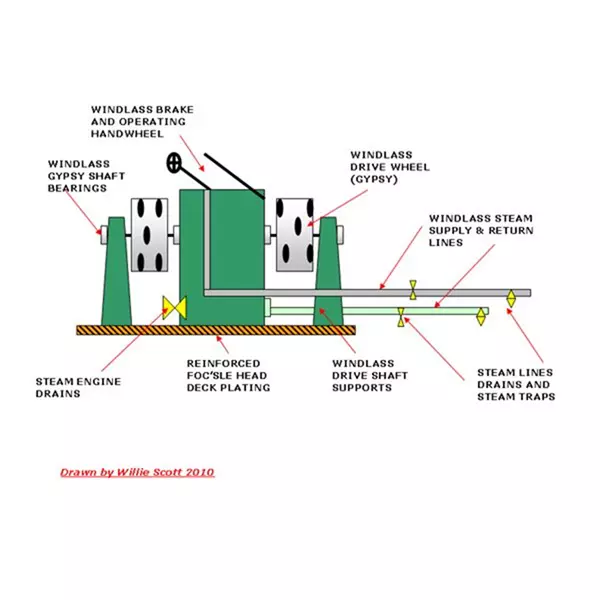

The windlass is used to raise or lower the ships anchor and is located on the focísle head. It has a normal steam engine which drives a single or dual horizontally mounted notched wheel known as gypsies. The notches in the wheels are forged or moulded to suit the chain links size and profile exactly to ensure efficient operation and prevent the chains from jumping off.There is also a gearbox and manual brake incorporated in the windlass operation.

Before starting the windlass should be thoroughly warmed through with all the relevant steam drains open. The operating hand-wheel which admits the steam to the windlass should be slowly rotated until the strain is taken, then further opened as the anchor chain is drawn in or lowered. A sketch of a twin drum steam windlass is shown below.

Galley Steam Supply

I have sailed with a few ships cooks who preferred cooking using steam ovens and steamers. Nowadays of course electric ovens are the norm, but I believe steam is still supplied to the galley for water heating and degreasing the galley deck and bulkheads.

Accommodation Heating†††††††††††††††††††††††††††††††††††††††††††††††††††††

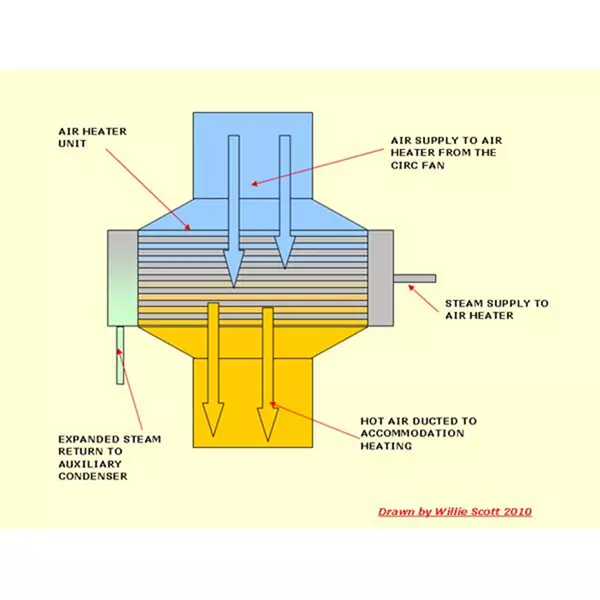

The steam supplies a heat exchanger through which air is blown and heated. This hot air is then circulated round the cabins and alleyways by a fan returning to the heat exchanger. The temperature is controlled by several instruments, some fitted to the individual cabins or at the exchanger hot air outlet.

The hot air ducting also doubles up as the air condition supply ducting when the A/C is operating.

A typical steam heater is shown below

Steam on Deck

So there we have it, steam on deck! Sadly gone out of fashion, but in its day provided a very simple, trouble-free means of operating the deck machinery and a joy to behold and work on. It was used for tank-cleaning on the oil tankers, being sprayed around the internals of the tank by a Butterworth Pump the hot steam washing the oil from the tank sides.

Steam is also supplied to an air heater used to heat the accommodation and to the galley for cooking and steam cleaning the stainless working surfaces and equipment.

The steam returns from these systems to an auxiliary condenser in the engine room where it is condensed and pumped to the boiler feed system.

A steam calorifier in the engine heats the domestic water for the accommodation showers etc.