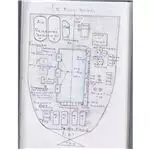

Layout Of Middle Level Of Engine Room

Introduction

We learnt about the engine room design and layout of the bottom most platform and saw the various machineries and equipment that can be found over there. Now we will proceed a step further (rather upward) and jump over to the next platform or the middle tier of the engine room and find out what all can you expect to see over there.

I must state at this stage, that though this would give you a general idea about the equipment layout, do not take this as a hard and fast rule which cannot be altered. So sometimes you might find some machinery or equipment at a different place or location than you have been reading in these articles. This is so because there are so many different types of ships having different uses and sizes etc, that it is not possible to generalize everything about all vessels.

You can expected to find the following pumps on the middle platform of the ship's engine room:

○ Main engine booster pump

○ Boiler feed pump

○ Fresh water condenser pump

○ Maine engine fuel pumps

Coolers

○ Jacket cooling water cooler

○ Main lube oil cooler

○ Fresh water generator cooler

Heaters

○ Purifier steam heater

○ Main engine fuel oil heater

Auxiliary Machinery

The following auxiliary machinery can be expected to be found at the middle level of the engine room

○ Main air compressor

○ Auxiliary / topping air compressor

○ Emergency air compressor.

○ Control air compressor

○ Dehumidifier

○ Fresh water generator

○ Auxiliary air blower for main engine.

○ Auxiliary generators / alternators.

○ Heavy oil purifier

○ Diesel oil purifier

Middle Platform Sketch

Reasons for Location

Sometimes the location of a particular machinery or equipment is not merely due to aesthetic or design reasons but there might be some operational features associated with the specific location. Given below is a list of reasons why some equipment is found at the middle platform

Why generators are provided at the middle platform?

Generator are provided at the middle platform because in the extreme situation of flooding of bottom platform. immediate shutdown of the power supply or black out condition can be avoided.

Why Fresh Water Generator is located at the middle platform?

For normal steam generation the temperature is equal to the boiling point of water that is at 100

o c at atmospheric pressure. In fresh water generator the temperature to which the sea water is heated is lower than that but because of it being at low pressure, the steam is generated. When the pressure is reduced, the boiling point of water also reduced; this is the basic principle behind the fresh water generator.

Normally the waste heat is used to heat water in the fresh water generator. Waste heat from the jacket cooling water or steam line can be connected for the purpose. If the fresh water is generated is located at the bottom platform, there would be a back pressure of sea water and sufficient vacuum will not be created. Hence the reason for it to be placed at the middle platform.

Why lube oil & heavy oil heaters are provided?

Heavy oil and lube oil is heated before entering the purifier for the effective purification of the oil, and since the purifiers are located at the middle tier, the heaters have to be there.

Air Bottles

Main air bottles contain air at a pressure of (25 -30 )kg/cm2. These bottles provide air for the starting of main engine. Compressed air from the air bottle is taken and pressure reduced to (6-8) kg/cm2 by the pressure reducing valve and this air is used for control and service purposes. As per regulations, the air in one of the main air bottle with other air bottle closed and with out the compressor running should be enough to give at least 12 continuous KICKS / MOVEMENTS to the main engine .

Mainly vertical air bottles are used for less space consumption.

Auxiliary air bottles are used for the auxiliary engines.

Emergency air bottle is used to start the emergency generator in case of power failure and gives control air for the QCV (quick closing valve).