The Charge Air Cooler in Diesel Engines

The charge air cooler is an important device fitted in all turbocharged diesel engines to reduce the temperature of the charged air before its entry to the engine in order to increase the efficiency of engine. This article deals with purpose, location, and maintenance of charge air coolers.

In this article we discuss the charge air cooler fitted between the turbocharger and the scavenge air manifold in all modern four stroke and two stroke engines. Readers will be able to understand the concept of charge air coolers, and their operation, construction, and maintenance. One can also find reasons for cooler fouling, its location on engine, and methods of cleaning the charge air cooler.

Purpose of Charge Air Cooler

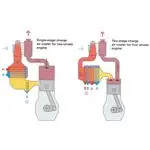

The exhaust gas from the engine is utilized in the turbocharger for compressing fresh air to charge the engine with a positive pressure greater than ambient conditions. This compression causes the temperature of the air to increase, which thus cannot be fed directly into the engine as it is out of operating limits. Thus a cooler that bring the air temperature back to near-ambient conditions is fitted on the engine. When the air is hot, its density is less and thus the mass of air charged into the engine is less when compared to the mass when the air is cold. Thus the charge air cooler improves the charge air density and its temperature.

The compressed charged air at the outlet of charge air cooler will have a reduced temperature of about 40 to 50 degrees Celsius from a temperature of about 200 degrees Celsius. This reduced temperature of air will increase the density of the charge air at low temperature. Increased air density of the charge air will rise the scavenge efficiency and allow a greater mass of air to be compressed inside the engine cylinder so that more fuel can be burned inside the combustion chamber, giving an increase in power. Also the engine is maintained at a safe working temperature. The lower compression temperature reduces stress on the piston, piston rings, cylinder liner, and cylinder head. The charge air cooler has another advantage in that it reduces the exhaust gas temperature. It has been proven that every one degree Celsius drop in scavenge air temperature will reduce the exhaust temperature about five to ten degree Celsius. This does not mean that the air can be charged at cryogenic temperatures. If very cold air enters the cylinder liner, it would cause a sudden thermal shock, leading to cracking of liner.

Thus charge air coolers also serve as heaters when a ship enters cold climate areas. Let us assume that the charge air cooler is cooled by fresh water (LT) circuit. If the ambient air temperature is very low, the fresh water, which is usually at 30 degrees Celsius, will heat the charged air and make it comfortable for the engine.

Charge Air Cooler

Location of a Charge Air Cooler

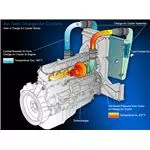

Charge air coolers are located between the turbocharger compressor side outlet and the engine inlet manifold or scavenge manifold. A clear view of the location of a charge air cooler is shown in the diagram below. The location of the charge air cooler between turbocharger and entry to engine should be such that the temperature of the charge air at the outlet of charge air cooler should not be increased before its entry to the engine cylinder due to the heated condition of the engine room. To avoid this, the air cooler should be located as close to the engine cylinder as possible. Also, the air duct between the charge air cooler and the engine inlet manifold should be insulated to avoid increase in the temperature of the air.

Location of Cooler on Large Diesel Engine

Air Cooler Fouling and its Effect on the Engine

When the air cooler becomes fouled, less heat will be transferred from the air to the cooling water (usually fresh water). This is indicated by the changes in the air temperature and cooling water temperature and a pressure drop in the air passing through the air cooler. To measure this pressure drop, a manometer is connected between the charge air cooler inlet and outlet. The amount of pressure drop will depend upon the degree and nature of the fouling.

Indications of Air Side Fouling:

○ Increase of air pressure drop across the charge air cooler.

○ Decrease of air temperature difference across air cooler.

○ Rise in scavenge air temperature.

○ Rise in exhaust gas temperature from all cylinders.

Indications of cooling water side fouling:

○ Rise in scavenge air temperature.

○ Decrease in the difference of the air temperature across the air cooler.

○ Decrease in the temperature of the cooling water across the cooler if fouling is on the tubes.

○ Increase in exhaust gas temperature from all cylinders.

○ Increase in the temperature of the cooling water due to fouling or chocking material in tubes that reduce the amount of cooling water flow.

Methods of air side cleaning:

○ Fins in the air side can be cleaned by using compressed air at Low pressure.

○ The air side can be cleaned by dipping the air cooler in a chemical bath for a certain period of time. This will remove all deposits on the air side.

○ Another method of cleaning the air side is by using the jet of water at Low pressure.

○ Note: Usage of very high pressure may lead to bending of fins and thus causing permanent damage to the air cooler.

Methods of Fresh water side cleaning:

○ For soft deposits on the water side, dip the cooler in a chemical bath. After a certain period of time, take the cooler out and then clean with water at some temperature higher than ambient. It is always preferred to circulate water using wilden pump and drums.

○ For hard deposits use a long drill bit to drill the hard deposits on the tubes. Note this requires a specialist to drill the hard deposits because small mistakes in drilling may damage the tubes.