Hybrid Turbocharger for Marine Engines: Maritime Technology Innovation

Lately, the maritime sector has been investing heavily in R&D to cut down harmful emissions from the ship, along with reducing fuel consumption and operating cost. Maritime market has seen several developments in the past mainly for developing waste energy recovery systems such as economiser, turbocharger etc. A marine technology innovation has taken the research to all new level and to a step ahead. It is called the Hybrid Turbocharger.

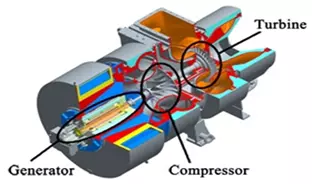

Hybrid turbocharger is developed by Mitsubishi heavy industries and it differs from conventional turbochargers in terms of both waste recovery and fuel saving. Exhaust gas energy is recovered to turn the compressor, which supplies scavenge air to the main engine and also generates electricity through an alternator attachment incorporated in the turbocharger known as MET hybrid turbocharger

The turbine and compressor does the heat energy recovery work and the alternator is used to generate electrical power without consuming any extra fuel as it is driven by the shaft power of the turbocharger.

Requirements for setting up hybrid turbocharger

For a hybrid turbocharger, three basic things required are:

1. Conventional turbocharger with extended shaft to accommodate alternator at blower end.

2. A specially designed very compact alternator to run at very high speed of around 9000 rpm.

3. A cooling system for alternator as heat generated will be more due to its compact size for given rpm.

Construction of hybrid turbocharger

A two part shell made from cast steel is fitted to the blower side scroll, which is built up with higher rigidity, in order to support alternator within the turbocharger silencer.

The lower half shell is attached first and is made such that it acts like a sump to collect lubricating oil discharged from the alternator.

Intake filter and silencer are mounted above the alternator assembly with sufficient gap to allow air to pass over the shell into the compressor blades.

Cooling water jacket made up of aluminium is provided around the rotor winding and external cooling air is also supplied at extreme ends and centre of the windings.

The alternator and compressor are connected by special designed flexible coupling.

The length and weight of the Hybrid T/C is 313mm and 4600kg more as compare to conventional system.

Working of Hybrid Turbocharger

The working is similar to any other generator, the only difference here is the prime mover which is turbocharger itself.

The speed of prime mover governs the voltage and frequency of the generator. An initial D.C power is provided so that the required output voltage and frequency can be achieved.

At 9500 KW, the hybrid system can generate about 756 KW which is enough to take up full sea load of a normal size merchant vessel.

Advantages

● With only little increase in the dimensions, enough power can be generated from main engine operation.

● Fuel saving as the heat recovery system is used for driving the alternator.

● The generator can function as motor at low load operation to drive blower for maintaining scavenge air pressure of the main engine.

● Eliminate the installation of auxiliary blower for main engine.

● As no extra fuel is used, it helps in emission cut down from ship.

Application

MV Shin Koho, a 292 m long 180,000 dwt bulk carrier with a draft of 24.5m is the world’s first merchant vessel to successfully equipped with the hybrid turbocharger technology.