How to know if the Piston is at Top Dead Center?

††  ††

††

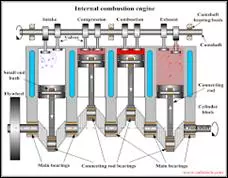

During the maintenance of the marine engines we have to ascertain that the piston is at TDC to check tappet clearance. Though markings are provided on the flywheel, the marine engineer must know the other methods like inspection of camshaft and fuel pump window.

What is the need to know the TDC Position of Piston

During the maintenance of a four stroke marine diesel engine there are times when we must know whether the particular unitís piston is at the top dead center of not. For example during the checking the tappet clearances of the engine it is important to know which unit is at TDC. Referring the flywheel would indicate two units, but only one can be at injection TDC.

So which one is it? In this article the various methods to find out the position of the piston would be discussed. Some are very simple and conventional methods but some are little complicated but never the less very important when you require an independent method to find the TDC.

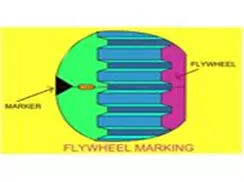

Flywheel Method

The flywheel is the simplest method to know which unit is at TDC. If the flywheel shows two units, simply open the bonnet covers and check visually. The unit at TDC would be having both the inlet and the exhaust valve closed and hence relaxed springs; the other unit would have both the arms of the rocker arm at different levels. In addition the push rods of the unit at TDC would be loose and can be turned by hand because of the release of the clearances.

There is a word of caution however this method is only useful in a working generator which you have just stopped to check the tappet clearances. In case you have removed the rocker arms for any reason the spring height and the push rod freeness check would lead you nowhere and misguide you.

Flywheel Marking

Fuel Pump Method

The most accurate method to know the position of the piston without opening up the piston is the fuel pump window. The fuel pumps have a window and as the plunger goes up and down, so does the mark on the bottom spring holder. On the body of the fuel pump there are cut marks which start the start of injection.

†In a diesel engine the start of injection is the injection TDC where both the inlet and the exhaust valves are closed. In this injection TDC we can check the tappet clearance. It must be noted however that the injection TDC is not the absolute TDC as the piston is still some way down depending on the design of the engine. An injection TDC may be around 5 degrees before TDC.

Dial Gauge Method

In this method the fuel injector is taken out and from the opening a dial gauge is put inside. Then the turning gear is engaged and the engine turned over. The pointer of the dial gauge will move in one direction and then stop and start in opposite direction.

†The moment the pointer of the dial gauge stops and changes its direction of movement is the TDC of the unit. This method is not normally used in day to day practice, but may be used in the calibration of the flywheel if it is not calibrated or after some repairs.

Dial Gauge

†††††††††††††††

Camshaft Method

The camshaft window of the engine can be opened up and the camshaft inspected. The cam of the engine has a base circle, acceleration and the dwell period. If the roller of the follower is at the base circle then the particular valve is closed by spring action. When both the exhaust valve and the inlet valve follower are on the base circle then also the unit is at TDC.

It must be remembered that as a four stroke engine has two rotation of the crankshaft there is one injection TDC where the injection and the combustion take place the second time the piston is at TDC is when the exhausting of the flue gases take place. It is very important to identify the combustion TDC as tappets have to be adjusted at that point.

Cam Profile

†††††††††††††††††††††††††††††††††

Crankcase Method

In this method the crankcase doors are opened up and the piston is visually checked whether is going up or down. This is the surest method but a bit cumbersome. It should be used when you have a strong doubt about the other methods.

Valve spring Method

This is not an independent method but is used in conjunction with the flywheel method. In this method if the flywheel is indicating two units, you can check the springs of both the units.

The unit the springs are loose at is the one at TDC. The caution is that this method is useful for an engine in use. If you have removed the rocker arms during the overhaul and thereafter you want to use this method than it can cause errors.

Push Rod Method

This method is like the spring method and you check that the push rods are free to turn. The unit at TDC will have loose springs. The care that must be taken is that it should be used along with the flywheel method and should be used in a working engine. By a working engine, I mean the engine that was running and has been stopped for tappets adjustment.

Spill Timing Method

This is a very accurate and tedious method and generally used to check the start of injection of the fuel pump. It will also give you the injection TDC. It is not used in tappets checking process but used to find the start of injection when you have power or thermal balance problems.

Basically in this method the delivery valve of the fuel pump along with the delivery valve spring are removed. Thereafter a special "U" shaped pipe is put in place of the high pressure pipe. After this operation the engine is turned by the turning gear and slowly brought near the expected TDC.

Soon oil will start spilling out of the pipe because the oil is entering from the inlet port which is uncovered by the plunger. Keep turning the engine slowly and the oil quantity will reduce. The point where the oil flow just stops is the start of the injection. At this moment the plunger of the fuel pump has closed the inlet port and if you observe the fuel cam you will find the follower is no longer at the base circle.

As this method involves the spilling of fuel, it is called as the spill timing method.

Conclusion

There are various methods by which the TDC can be found. The simplest and the most straightforward method is the reference of the flywheel, but sometimes the flywheel itself is changed and you need to calibrate the new one. Sometimes to check if the slippage of the crankshaft has taken place you need two methods, especially where the crankshaft does not have marks to indicate slippage.