INTERNAL COMBUSTION ENGINES

The internal combustion (IC) engine has been the dominant prime mover in our society since its invention in the last quarter of the 19th century [for more details see, for example, Heywood (1988)]. Its purpose is to generate mechanical power from the chemical energy contained in the fuel and released through combustion of the fuel inside the engine. It is this specific point, that fuel is burned inside the work-producing part of the engine, that gives IC engines their name and distinguishes them from other types such as external combustion engines. Although Gas Turbines satisfy the definition of an IC engine, the term has been traditionally associated with spark-ignition (sometimes called Otto, gasoline or petrol engines) and diesel engines (or compression-ignition engines).

Internal combustion engines are used in applications ranging from marine propulsion and power generating sets with capacity exceeding 100 MW to hand-held tools where the power delivered is less than 100 W. This implies that the size and characteristics of today's engines vary widely between large diesels having cylinder bores exceeding 1,000 mm and reciprocating at speeds as low as 100 rpm to small gasoline two-stroke engines with cylinder bores around 20 mm. Within these two extremes lie medium-speed diesel engines, heavy-duty automotive diesels, truck and passenger car engines, aircraft engines, motorcycle engines and small industrial engines. From all these types, the passenger car gasoline and diesel engines have a prominent position since they are, by far, the largest produced engines in the world; as such, their influence on social and economic life is of paramount importance.

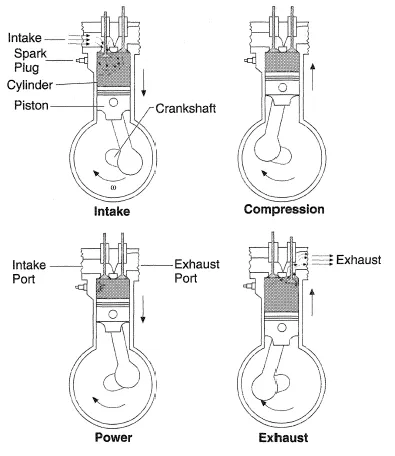

The majority of reciprocating internal combustion engines operate on what is known as the four-stroke cycle (Figure 1), which is subdivided into four processes: intake, compression, expansion/ power and exhaust. Each engine cylinder requires four strokes of its piston which corresponds to two crankshaft revolutions to complete the sequence which lead to the production of power.

Figure 1. Four-stroke engine cycle.

The intake stroke is initiated by the downward movement of the piston, which draws into the cylinder fresh fuel/air mixture through the port/valve assembly, and ends when the piston reaches bottom-dead-center (BDC). The mixture is generated either by means of a carburetor (as in conventional engines) or by injection of gasoline at low pressure into the intake port through an eiectronically-controlled pintle-type injector (as in more advanced engines). Effectively, the induction process starts with the opening of the intake valve just before top-dead-center (TDC) and ends when the intake valve (or valves in four-valve per-cylinder engines) closes shortly after BDC. The closing time of the intake valve(s) is a function of the design of the induction manifold, which influences the gas dynamics and volumetric efficiency of the engine, and engine speed.

The intake stroke is succeeded by the compression stroke which effectively starts at the intake valve closure. Its purpose is to prepare the mixture for combustion by increasing its temperature and pressure. Combustion is initiated by the energy released through the spark plug towards the end of the compression stroke and is associated with a rapid rise in the cylinder pressure.

The power or expansion stroke starts with the piston at TDC of compression and ends at BDC. At this point, the high temperature and pressure gases generated during combustion push the piston down, thus forcing the crank to rotate. Just before the piston reaches BDC, the exhaust valve(s) opens and the burned gases are allowed to exit the cylinder due to the differential pressure between the cylinder and the exhaust manifold.

This exhaust stroke completes the engine cycle by evacuating the cylinder from burned, partially-burned or even unburned gases escaping the combustion process; the next engine cycle starts when the intake valve opens near TDC and the exhaust valve closes a few degrees crank angle later.

It is important to note that the properties of gasoline, in association with combustion chamber geometry, exert a significant influence on combustion duration, rate of pressure rise and pollutant formation. Under certain conditions, the mixture at the end gas may autoignite before the flame reaches that part of the cylinder, leading to knock which gives rise to high-intensity and frequency pressure oscillations.

The tendency of gasoline fuel to resist autoignition and thus prevent possible damage to the engine as a result of knock is characterised by its octane number. Until recently, the addition of a small quantity of lead into the gasoline was the preferred method for suppressing knock but the associated health risks, combined with the need to use catalysts for reducing exhaust emissions, have necessitated the introduction of unleaded gasoline. This requires a reduction of the engine's compression ratio (ratio of the cylinder volume at BDC to the volume at TDC) in order to prevent knock with undesirable effects on thermal efficiency.

As already mentioned, the four-stroke cycle, also known as Otto cycle after its inventor Nicolaus Otto who built the first engine in 1876, produces a power stroke for every two crankshaft revolutions. One way to increase the power output of a given engine size is to convert it to a two-stroke cycle (Figure 2) in which power is produced during every engine revolution.

Figure 2. Two-stroke engine cycle.

Because this mode of operation gives rise to increased power output—albeit not to the double levels expected from simple calculations—it has been extensively used in motorcycle, passenger car and marine applications with both spark-ignition and diesel engines. An additional advantage is the simple design of two-stroke engines since they can operate with side ports in the liner, covered and uncovered by piston motion, instead of the bulky and complicated overhead cam arrangement.

In the two-stroke cycle, the compression stroke starts after the inlet and exhaust side ports are covered by the piston; the fuel/air mixture is compressed and then ignited by a spark-plug, similar to ignition in a four-stroke gasoline engine, to initiate combustion near TDC. At the same time, fresh charge is allowed to enter the crankcase before its subsequent compression by the downward-moving piston during the power or expansion stroke. Daring this period, burned gases push the piston until it reaches BDC, which allows first the exhaust ports and then the intake (transfer) ports to be uncovered. The opening of the exhaust ports permits the burned gases to exit the cylinder while partly at the same time the fresh charge, which has been compressed in the crankcase, enters the cylinder through the properly orientated transfer ports.

The overlapping of the induction and exhaust strokes in two-stroke cycle engines is responsible for some of the fresh charge flowing directly out of the cylinder during the scavenging process. Despite various attempts to reduce the magnitude of this problem by introducing a deflector into the piston (Figure 2) and directing the incoming charge away from the location of the exhaust ports, charging efficiency in conventional two-stroke engines remains relatively low. A solution to this problem is to introduce the fuel directly into the cylinder, separately from the fresh air, through air-assisted injectors during the period when both the exhaust and transfer ports are closed. Despite the short period available for mixing, air-assisted atomizers can achieve a homogeneous lean mixture at the time of ignition by generating gasoline droplets of less than 40 μm mean diameter, which vaporize very easily during the compression stroke.

Amongst the various types of internal combustion engines, the diesel or compression-ignition engine is renowned for its high efficiency, reduced fuel consumption and relatively low total gaseous emissions. Its name comes from the German engineer Rudolf Diesel (1858−1913) who in 1892 described in his patent a form of internal combustion engine which does not require an external source of ignition and where combustion is initiated by the autoignition of the liquid fuel injected into the high temperature and pressure air towards the end of the compression stroke.

The inherent efficiency advantages of the diesel engine stem from its lean overall mixture ratios, the high engine compression ratios afforded due to the absence of end-gas ignition (knock) and the greater expansion ratios. As a consequence, diesel engines in either the two-stroke or four-stroke configuration have been traditionally the preferred power plants for commercial applications such as ships/boats, energy-generating sets, locomotives and tracks and, over the last 20 years or so, passenger cars as well especially in Europe.

The low power-output disadvantage of diesel engines has been circumvented by the use of superchargers or turbochargers which increase the power/weight ratio of an engine through an increase of the inlet air density. Turbochargers are expected to become standard components of all future diesel engines, irrespective of application.

The operation of the diesel engine differs from that of the spark-ignition engine mainly in the way the mixture is formed prior to combustion. Only air is inducted into the engine through a helical or directed port and the fuel mixes with air during the compression stroke, following its injection at high pressure into a prechamber indirect-injection diesel or IDI) or into the main chamber (direct-injection diesel or DI) just, before combustion is started.

The need to achieve good fuel/air mixing in diesel engines is satisfied by high-pressure fuel injection systems which generate droplets of about 40 μm mean diameter. For passenger cars, the fuel injection systems consist of a rotary pump, delivery pipes and fuel injector nozzles which vary in their design according to the application; direct-injection diesel engines use hole-type nozzles while indirect-injection diesels employ pintle-type nozzles. Larger diesel engines use in-line fuel-injection pumps, unit injectors (pump and nozzle combined in one unit) or individual single-barrel pumps which are mounted close to each cylinder.

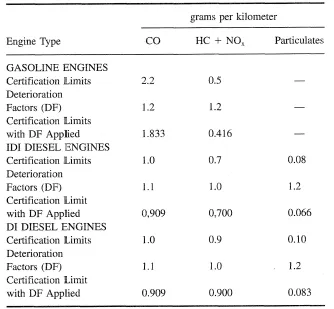

Over the last 20 years or so, the realization that the resources of crude oil are finite and that the environment we live in is becoming more and more polluted, has urged governments to introduce laws which limit the exhaust emission levels of vehicles and engines of all types. Since their introduction in Japan and the USA in the late 60s and in Europe in 1970, emission regulations are consistently becoming more stringent and engine manufacturers are facing their toughest ever challenge with the standards agreed for 1996 onwards, which are summarized for passenger cars in Table 1. It is expected that the new standards to be imposed in Europe for the year 2000 will be even lower, following Californian levels which require zero emission levels after the turn of the century. However, it is uncertain whether existing engines will satisfy these limits despite the desperate attempts by engineers worldwide.

Table 1. European Emission Standards for 1996

Figure 3. Model of a three-way catalytic converter.

It is clear from Table 1 that the major pollutants in spark-ignition engines are hydrocarbons (HC), carbon monoxide (CO) and oxides of nitrogen (NOx = NO + NO2) while in diesel engines, NOx and particulates—which consist of soot particles formed during combustion of lubricating oil and hydrocarbons—are the most harmful.

At present three-way catalysts, which are a standard component of today's passenger cars equipped with spark-ignition engine running on unleaded gasoline, allow about 90% reduction of the emitted HC, CO and NOx by converting them into carbon dioxide (CO2), water (H2O) and N2.

Unfortunately these catalysts require stoichiometric (air-fuel ratio of ~14.5) engine operation, which is undesirable from both the fuel consumption and CO2 emissions points of view. An alternative approach is the lean burn concept which offers promise for simultaneous reduction of fuel consumption and exhaust emissions through satisfactory combustion of lean mixtures with much higher than 20 air-fuel ratios. It is expected that the development of lean burn catalysts with conversion efficiencies over 60% may allow lean burn engines to satisfy future emissions legislation; this is an area of active research in both industry and academia. On the other hand, new diesel engines depend on two-way or oxidizing catalysts for reduction of exhaust particulates through conversion of HC into CO2 and H2O, and on exhaust gas recirculation and retarded injection timing for reduction of NOx levels.