Lamont Boiler

Lamont Boiler is a water tube boiler and It is a high-pressure boiler.

The other different types of water tube boiler: Benson boiler, Stirling boiler, Babcock and Wilcox boiler, Yarrow boiler and Loeffler boiler.

Here we are going to study Definition, Main Parts, Working, Application, Advantages, Disadvantages of Lamont Boiler and you can download whole articles in PDF at the end.

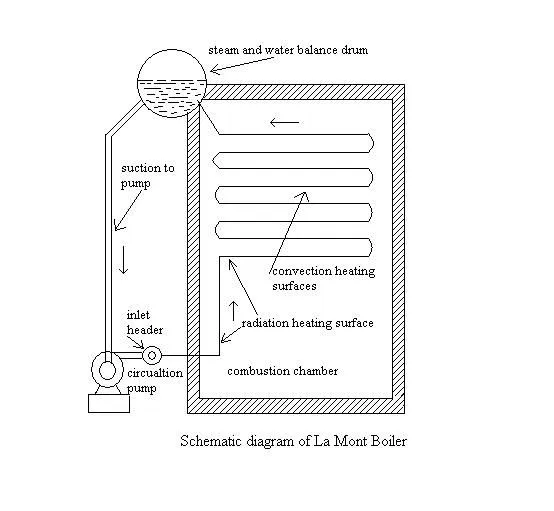

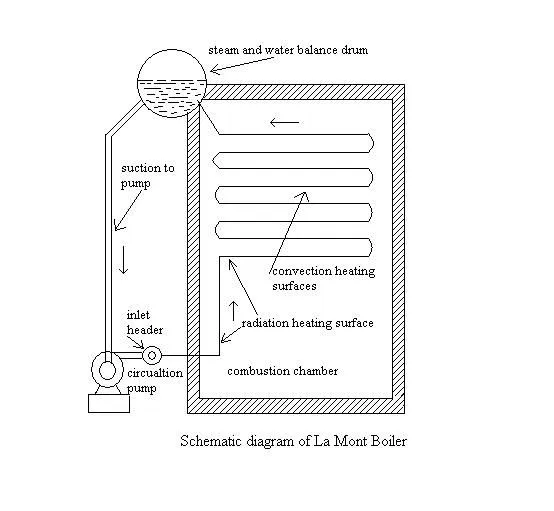

LaMont boiler is a high pressure forced circulation water-tube boiler in which water is circulated through an external pump through long closely spaced tubes of small diameter.

The pump is employed in order to have adequate and positive circulation in steam and hot water boilers.

A Lamont Boiler consists of several parts like:

· Economizer

· Centrifugal Pump

· Evaporator Tube

· Grate

· Furnace

· Superheater

· Water Steam Separator Drum

· Air Preheater

Economizer use to preheat the water by using the remaining heat of the combustion gases.

The feed water first supplied to the economizer before entering the boiler.

Economizer is a device that is used to increases boiler efficiency.

The Lamont boiler is a force convection boiler. So a centrifugal pump is used to circulate water inside the boiler.

This pump is driven by a steam turbine. The steam for the turbine is taken by the boiler.

The evaporator tube or can say water tubes are situated at the furnace wall which increases the heating surface of the boiler.

This is also at the upside and downside of the furnace and other equipment.

The main function of these tubes to evaporate water into steam.

This also cools down the furnace wall.

The space in the furnace where the fuel is burned is called grate.

It is placed at the bottom side of the furnace.

In the Lamont boiler vertical furnace is used.

The main function of the furnace is to burn the fuel.

The steam generated by the evaporator tube is saturated steam.

If it directly used in the steam turbine can cause corrosion.

So the saturated steam sends to the upper heater, where it can increase the temperature of the steam.

The steam separator is situated outside of the boiler.

The mixture of water and steam from the evaporator tube sends it to the steam separator, where it separates the stem and sends it to the superheater.

The remaining water again sends to the economizer.

The main function to preheat air before entering into the furnace.

Air preheater is a device that increases the efficiency of the boiler.