Maintenance of Butterfly Valve on Ships

Butterfly valve allows bi-directional flow of fluids and provide air tight shutoff at full rated pressure.

Advantages of Butterfly Valve

· They offer very little resistance to the fluid when compared to equivalent globe valves.

· They occupy very little space.

· Can be easily operated by hydraulic or pneumatic actuators.

· Can be opened or shut by quarter turn.

· Possible to throttle the flow without damaging the valve.

· Can be easily installed or replaced.

· Need very little maintenance.

Instructions for Installation of Butterfly valve

· Verify that the nominal dimensions of the valve and pipe line matches.

· Spread the flange enough to allow the valves with disc in closed position. This prevents the damage of disc and seat during installation.

· It is recommended that the flange gaskets are not to be provided.

· Insert the bolts through the two bottom pipe flange holes to rest valve on during installation.

· Insert the remaining flange bolts after aligning the valve with flanges and tighten bolts partially.

· Adjust open and close operation of the valve to be easy and smooth.

· Open the valve completely and tighten the flange bolts evenly with adequate torque to prevent the leakage between flange and valve.

The Procedure of Butterfly Valve Disassembly

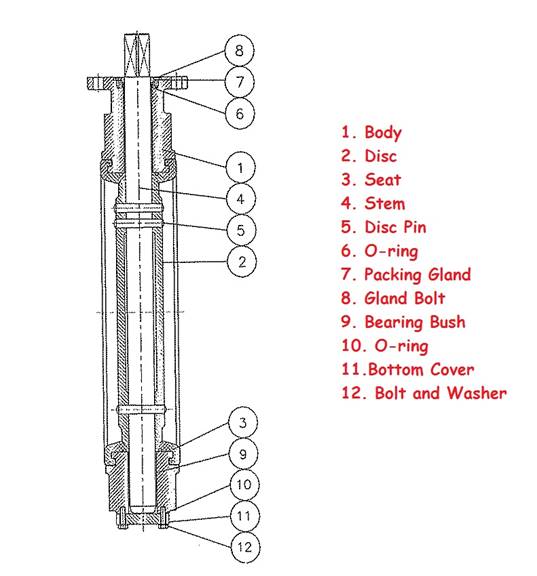

Refer to the diagram below to understand different parts of butterfly valve while dismantling and reassembly. Please note that the parts 10, 11 and 12 may be present only in bigger butterfly valves. Make sure the pipe line is not under pressure and line contents drained properly, before dismantling valve from the system. If the valve is fitted with hydraulic or pneumatic actuator, release the actuator pressure and isolate. Remove the actuator.

· Turn the disc (2) to closed position. Loosen and remove all flange bolting. Spread the flange if necessary and remove the valve from the pipeline.

· Remove the taper pins (6) in the disc (2).

· Remove the packing gland (7).

· Remove the stem (4) by pulling it out through the valve top plate.

· Remove the disc (2) from the valve body (1) by pulling or rolling the disc out of the seat bore.

· Collapse the seat (3) into the shape of a round bottom heart and pull it out of the body grooves.

· Remove the o-rings (6) and (10) and inspect. Renew if necessary.

Inspection of Butterfly Valve

Before assembly carry out following checks:

· Inspect body for any deformation, cracks, etc. Any deformation in the body results in improper positioning of the seat which leads to poor sealing of the valve.

· Confirm disc is intact without bend and perfectly sealing with the seat.

· Check the condition of the seat (flexibility) and renew if necessary.

· Check for straightness of stem spindle.

· Check the condition of packing gland and o-ring, renew if necessary. Damaged o-ring causes leakage through packing gland.

Assembly of Butterfly Valve

· Clean all the parts. Use silicone base oil or lubricant to facilitate assembly.

· Install bearing bush (9) into the valve body.

· Insert the seat (3) into the valve body. Take care to align the holes in seat and body for easy passage of stem (4).

· Install disc (2) into the valve seat (3) with taper pin holes toward the valve top plate and align stem holes.

· Install packing o-ring (6).

· Install packing gland (7) and secure it with screws.

· Install bottom cover (11).

· Align taper pin holes in the disc (2) with the holes in the stem (4) and install taper pins and tighten securely.