Abrasive jet machining (AJM) is one of the advanced machining processes (mechanical energy based) where a high velocity jet of abrasives is utilized to remove material from work surface by impact erosion. The abrasive jet is obtained by accelerating fine abrasive particles in highly pressurized gas (carrier gas). A nozzle is used to convert this pressure energy into kinetic energy and also to direct the jet towards work surface at a particular angle (impingement angle). Upon impact, hard abrasive particles gradually remove material by erosion and sometime assisted by brittle fracture.

AJM differs from age old sand blasting technique by the achievable level of accuracy and precision. AJM utilizes various abrasives including alumina, silicon carbide, glass beads, sodium bicarbonate, etc.; whereas sand blasting predominantly utilizes only silica sand (SiO2). Although purposes of both the processes are quite similar, cutting parameters can be controlled precisely in AJM and thus it can provide better accuracy and precision.

In AJM, it is assumed that hard abrasive particles participate in material removal action, while carrier gas assists to blow away eroded particles from machining zone. Such abrasives must possess few basic properties for efficient removal of material as well as to get desired quality of cut. Among the desired properties sufficient hardness, irregular shape, presence of sharp edges and good flow characteristics are essential.

Different abrasives having a range of grit size can be utilized based on workpiece material and the operation it is intended to perform. Aluminum oxide (alumina) of average grit size 10 – 50µm is commonly used for grooving and drilling operation, especially when work material is hard. However, for very hard work material, silicon carbide (SiC) is preferred as it is harder than alumina. For polishing and coating removal purposes, glass beads and crashed glass are conventionally used. Size of abrasives also influences quality of cut as well as material removal rate. Larger grit size tends to produce larger cavity and thus MRR improves with the sacrifice of surface finish. On the other hand, fine abrasives reduce MRR but improve surface quality and accuracy.

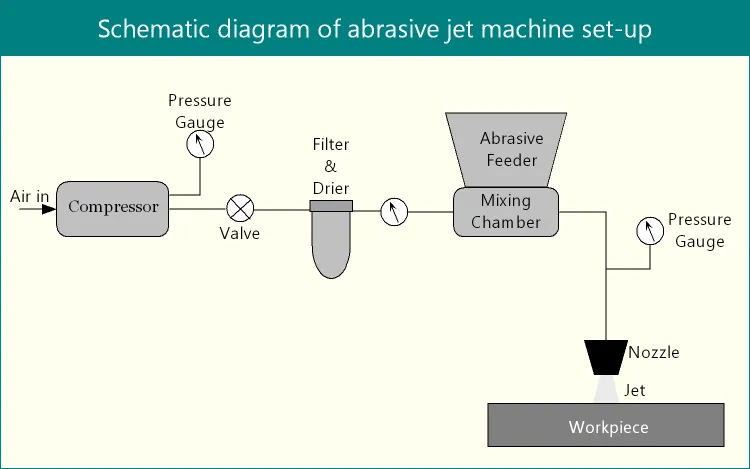

Basic purpose of carrier gas in abrasive jet machining is to accelerate fine abrasive particles (by momentum transfer). A compressor is used to elevate pressure of the carrier gas (as high as 20bar); abrasive grits are mixed with it in a mixing chamber (as per mixing ratio), and a nozzle is used to convert pressure energy into kinetic energy (in the form of high velocity jet). Carrier gas pressure along with nozzle diameter determines final jet velocity and thus machining performance.

Among various gases, air is commonly used in AJM as it is abundantly available at free of cost. Sometime commercially pure carbon di-oxide and nitrogen are also used to harness better performance for a particular purpose. However, pure oxygen is not used as it can quickly oxidize the work surface. Before compressing, carrier gas is dehumidified properly as presence of steam can block pipelines. When gas is compressed to high pressure, steam may condense and tiny water particles can create a larger globule after agglomerating with abrasives. Carrier gas is also made dust free before compressing to high pressure.

Primary function of nozzle in abrasive jet machining is to convert pressure energy of the pressurized gas-abrasive mixture into kinetic energy in the form of high velocity jet. Nozzle also directs high velocity jet towards work surface from a specific distance (called SOD) and at a particular predefined angle, called impingement angle. Inner diameter of the nozzle is paramount parameter as it determines final velocity and cross-sectional area of the jet for certain gas pressure. As flow rate and compressor delivery pressure are constant, jet velocity will be inversely proportional to the jet cross-sectional area.

Choosing nozzle material is another decisive factor from economic point of view. Usually tungsten carbide (WC) or sapphire nozzles are used in industrial applications. WC nozzles are cheaper but have limited life (20–30hr); while sapphire nozzles have extended life (150–200hr) but are costlier. Frequent changing of nozzle is associated with idle time during machining.

Air compressor: It compresses the carrier gas to a pressure of 15 – 20bar. Compressor unit also consists of drier and filter. So it removes water vapor and dust particles to avoid condensation or jamming during compression.

Pressure gauges: A number of such gauges are employed for measuring pressure of carrier gas as well as gas-abrasive mixture.

Flow regulating valves: These valves controls volume flow rate of carrier gas in order to maintain constant mixing ratio.

Hopper: In AJM, usually circular hopper with gradual compression is employed for continuously supplying fresh abrasive to the mixing chamber. Hopper is sometime vibrated to avoid bridging (jamming at outlet).

Mixing chamber: Its purpose is to mix abrasives with pressurized carrier gas. Here momentum transfer takes place and abrasives start flowing with carrier gas. Chamber is vibrated to obtain homogeneous mixing.

Nozzle: As an isentropic steady flow device, nozzle converts hydraulic energy (pressure) of the gas-abrasive mixture to the kinetic energy and thus high velocity jet is obtained.

Working chamber: A close working chamber, inbuilt with proper exhaust system, is usually maintained in order to avoid environmental pollution. It also helps protecting workers from lung dieses caused by exposing into atmosphere containing excessive tiny abrasive dust.

Servo controller: Sometime movement of work table is controlled by servo mechanism. This gives easy, accurate and precise control and is suitable for cutting intricate profiles and contours.

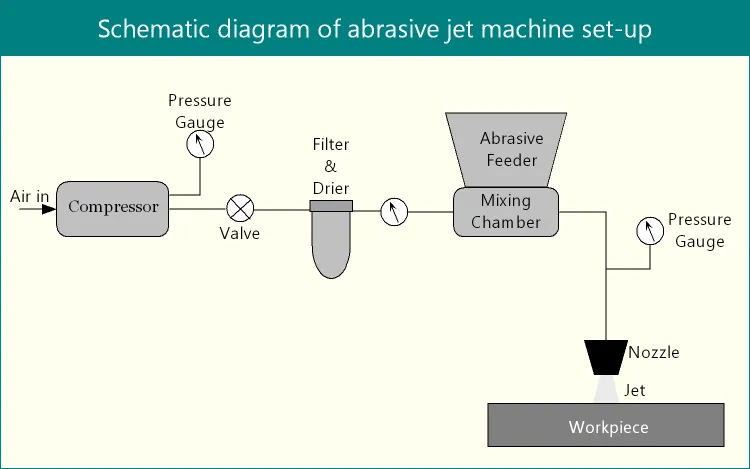

There are many factors that can influence abrasive jet machining performance. Important process parameters include (i) abrasive particles—its shape, size, strength, material and flow rate; (ii) carrier gas—its nature, composition, flow rate, pressure and temperature; (iii) abrasive jet—mixing ratio, striking velocity, impingement angle and stand-off distance; (iv) nozzle—its profile and inner diameter; and (v) work material—its mechanical properties and stress concentration.

AJM performance is usually assessed by analyzing three output responses, namely (i) material removal rate (MRR), (ii) surface roughness and accuracy of machined feature, and (iii) nozzle life or nozzle wear rate. Effects of process parameters on AJM performance are discussed below.

As discussed earlier, shape, size, strength, material and flow rate of abrasive can influence machining performance. Irregular shape abrasives having sharp edges tend to produce higher MRR as compared to spherical grits. Smaller size grits produce highly finished surface but reduce material removal rate (MRR) and thus productivity descends. Larger grits can again create trouble while mixing and flowing through the pipeline. However, variation in size in the entire volume should be low otherwise estimation or assessment will not be accurate.

Abrasive materials have varying strength or hardness. The harder is the abrasive with respect to work surface hardness, the larger will be the volume removal rate. It is basically the relative hardness between abrasives and workpiece that determines machining capability and productivity. Mass flow rate of abrasive is usually controlled by Mixing Ratio, whose effects are also discussed later in this section.

Carrier gas pressure and its flow rate are two paramount factors that determine performance and machining capability. Higher gas pressure reduces jet spreading and thus helps in cutting deeper slots accurately. However, various accessories including pipeline must be capable enough to handle such high pressure without failure. Moreover, increased gas flow rate gives the provision for utilizing higher abrasive flow rate, which can improve productivity.

Mixing ratio (M) is the ratio between mass flow rate of abrasive particles and mass flow rate of carrier gas. It basically determines concentration of abrasives in the jet. Mixing ratio can be increased by increasing abrasive percentage and in such case an increasing trend in MRR can be noticed because larger number of abrasives participates in micro-cutting action per unit time. However, excessive concentration of abrasive in the jet can significantly reduce MRR because of lower jet velocity (as gas pressure is constant) and unavoidable collision (thus loss of kinetic energy).

MRR can be enhanced by proportionally increasing both the abrasive flow rate and gas flow rate at same rate so that mixing ratio remains constant. In such case, higher pressure of the carrier gas has to be utilized. This necessitates thicker and stronger pipelines and other accessories to smoothly handle such high pressure without leakage and rupture. Indefinite increase in MRR is not practically feasible because of limited capability of equipment and accessories.

Distance from the work surface to the tip of nozzle in abrasive jet machining set-up is called Stand-Off Distance, abbreviated as SOD. Higher SOD causes spreading of jet and thus its cross-sectional area increases with the sacrifice of jet velocity. As a consequent, machining deeper slots or hole becomes difficult; instead a wider area is cut. Alternatively smaller SOD can cut a deeper but narrow slot or hole. It also enhances MRR. Thus an optimum value of stand-off distance is required to set for obtaining satisfactory performance in abrasive jet machining.

Impingement angle (θ), also called spray angle or impact angle, is basically the angle between the work surface and abrasive jet axis. Practically it is kept between 60º – 90º in order to get satisfactory performance in AJM. Larger angle tends to create deeper penetration, while smaller angle tends to increase machining area. An impingement angle (θ) between 70º – 80º provides better result in terms of material removal rate in abrasive jet machining.

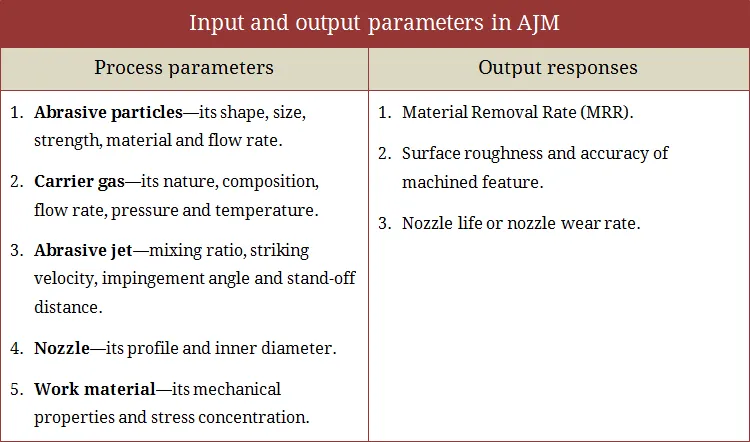

Knowledge of material removal rate (MRR) is beneficial for selecting process parameters and choosing feed rate of the nozzle. It also facilitates accurate estimation of productivity, delivery time as well as production cost. Since only kinetic energy of abrasive grits is utilized for erosion, the analytical formula for MRR can be established by equating available kinetic energy with the work done required for creating an indentation of certain cord length on a specific work material.

However, ductile and brittle materials behave differently in indent formation, and thus size of indentation created by the impact of single abrasive grit is different for ductile and brittle materials. Under few assumptions, MRR for abrasive jet machining for different materials can be modeled analytically and can be expressed as provided below.

Abrasive jet machining can be advantageously utilized for multifarious purposes including surface cleaning, deburring, abrading and even making holes. Common applications of abrasive jet machining process are provided below. It is to be noted that, irrespective of the purpose, abrasive jet machining (AJM) is beneficial only for hard and brittle materials. AJM should be avoided if work material is soft and ductile; otherwise quality of machined surface will be poor. Read also: Applications of AJM process.